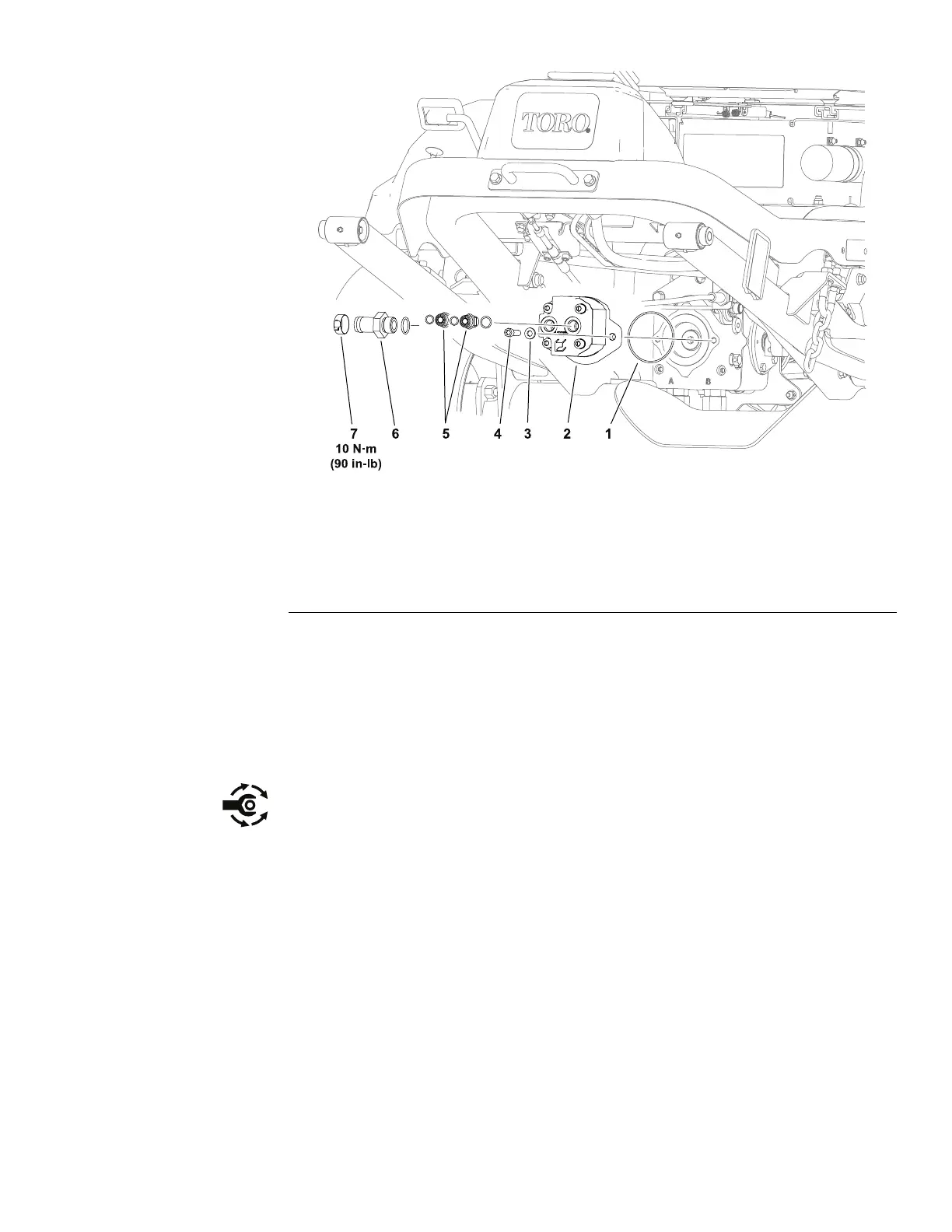

GearPump(P2)

g302898

Figure53

1.O-ring5.Straighttting

2.Gearpump6.Barbtting–suction

3.Washer(2each)

7.Hoseclamp

4.Capscrew(2each)

RemovingtheGearPump

Note:Thegearpump(P2)canberemovedseparatelyorwiththetraction

(piston)pump;refertoRemovingtheTraction(piston)Pump(page5–70).

RefertoFigure53forthisprocedure.

1.Parkthemachineonalevelsurface,lowerthecuttingunit(orattachment),

setthekeyswitchtotheOFFpositionandremovethekeyfromthekeyswitch.

2.Emptythehydraulictankthroughthedrainplugatthebottomofthetank.

UseanewO-ringandinstalltheplugwhennishedtopreventcontamination

fromenteringthehydraulicsystem.Tightenthedrainplugfrom18to19

N·m(155to171in-lb).

3.ReadandadheretotheinformationprovidedinGeneralPrecautionsfor

RemovingandInstallingtheHydraulicSystemComponents(page5–52).

4.Cleanthehydraulicpumpandallhydraulicconnectionstopreventhydraulic

systemcontamination.

5.Forassemblypurposes,labelallthehydraulicconnections.

6.Disconnectthehosesandtubesfromthettingsonthehydraulicpumpand

allowthehydrauliclinestodrainintoasuitablecontainer.

7.Installcleancapsorplugsontheopeningsofpumpanddisconnectedlines

topreventcontamination.

8.Removethefastenerssecuringthegearpumptothetraction(piston)pump

andseparatethegearpumpfromthetractionpump.Locateanddiscardthe

O-ringbetweenthepumps.

Groundsmaster

®

3200,3300and3310

Page5–75

HydraulicSystem:ServiceandRepairs

19240SLRevA

Loading...

Loading...