RemovingtheGearPump(continued)

Acasedrainexistsinthetraction(piston)pumpandasuctionportisnear

theinputshaftofthegearpump.Whenthegearpumpisremovedfromthe

tractionpump,installplugsintothecasedrainandsuctionportstoprevent

thepumpsfromdraining.

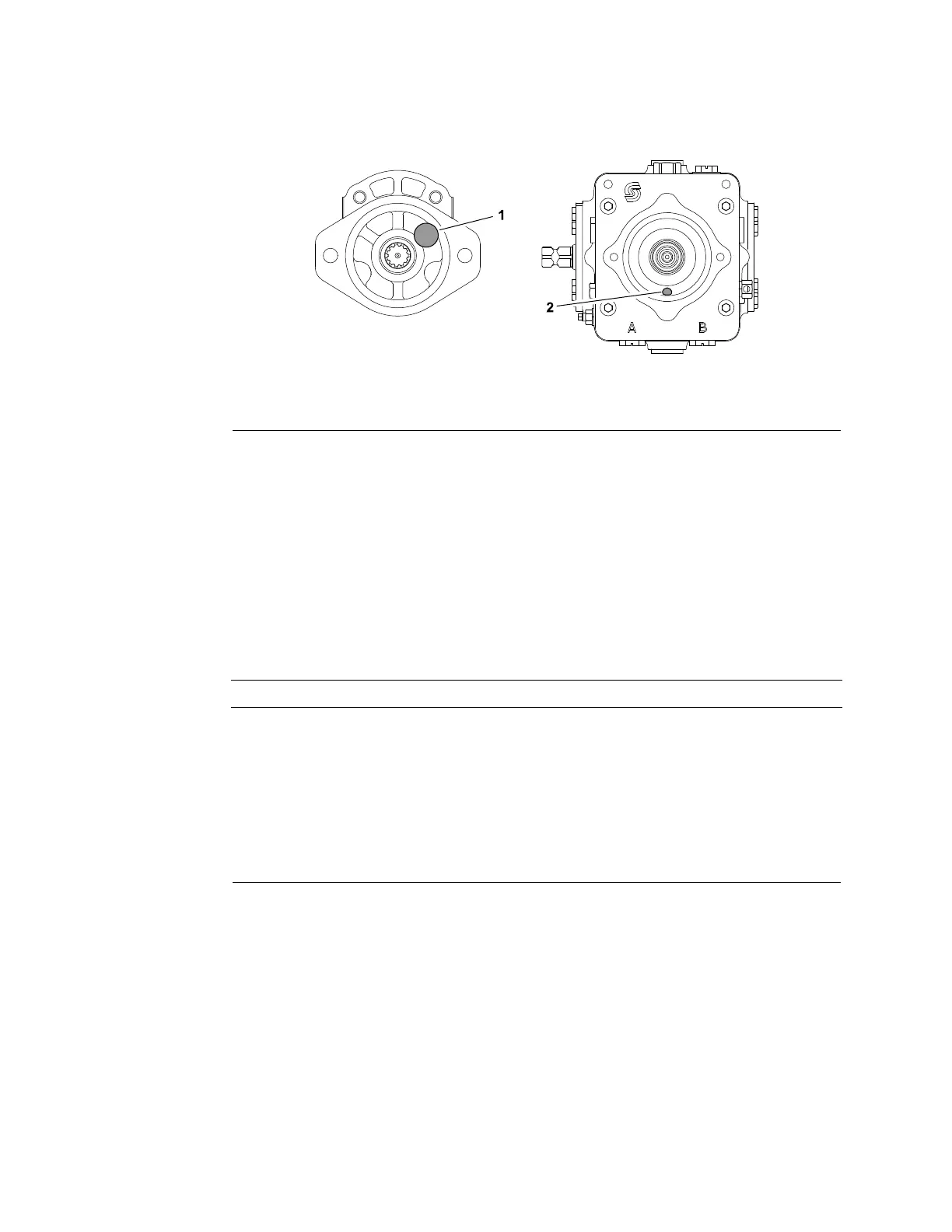

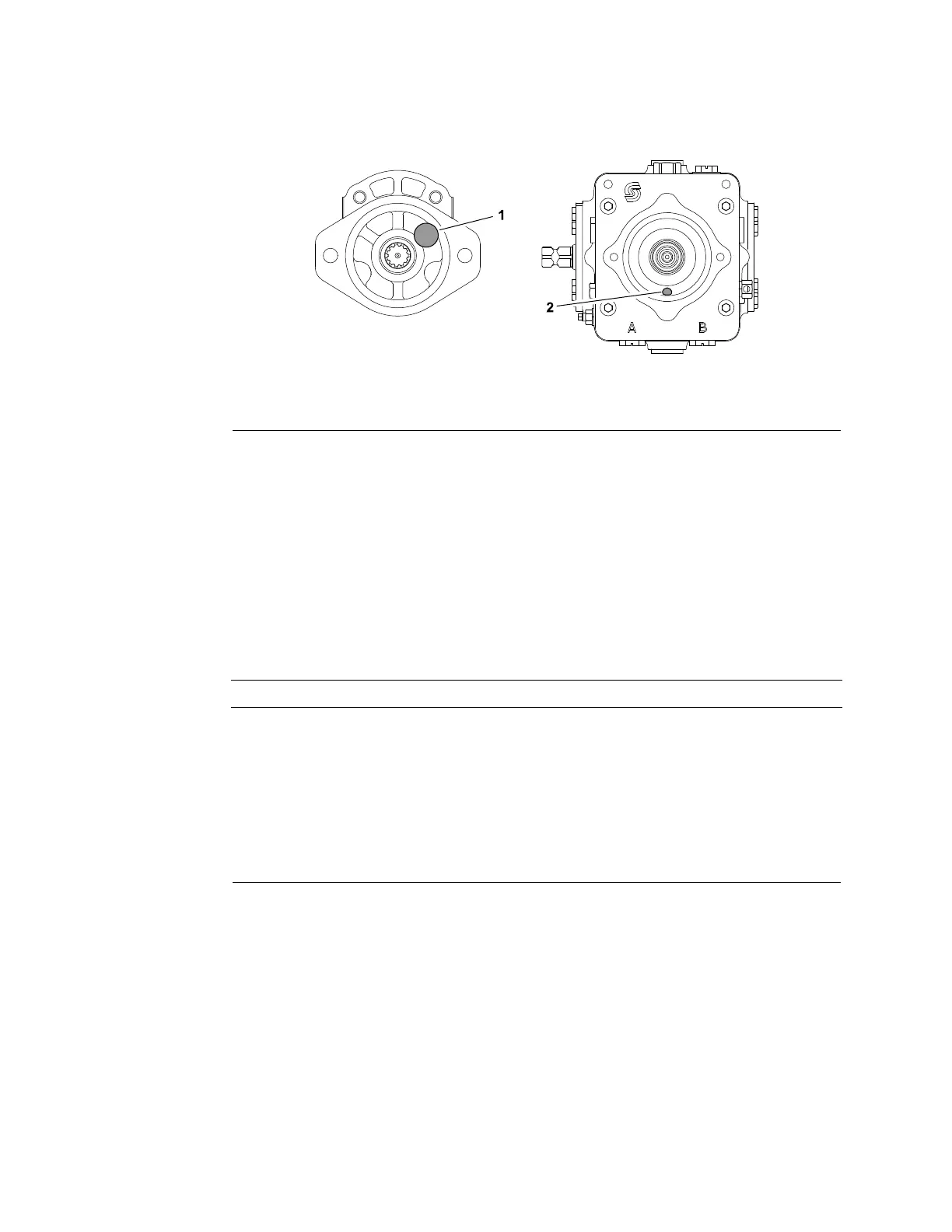

g213694

Figure54

1.Tractionpump(P1)casedrain2.Gearpump(P2)suctionport

9.Ifnecessary,removethehydraulicttingsfromthepump.Recordthe

locationsandorientationsofthettingsforassemblypurposes.

10.RemoveanddiscardalltheO-ringsfromthehydraulichoses,tubes,and

ttingsthatweredisconnectedorremoved.

InstallingtheGearPump

RefertoFigure53forthisprocedure.

1.LubricatenewO-ringsandplacethemontothettings.Ifpreviouslyremoved,

installthettingsintothepumpports;refertoInstallingtheHydraulicFittings

(SAEStraightThreadO-RingFittings)(page5–9).

IMPORTANT

Acasedrainexistsinthepiston(traction)pumpandasuctionport

isneartheinputshaftofthegearpump(Figure54).Beforethegear

pumpisinstalled,ensurethatanyplugsplacedineitherofthese

portsareremoved.Failuretoremovetheplugswillcauseexcessive

pressureinthepistonpumpanddamagetheseals.Also,before

securingthegearpumptopistonpump,llthepistonpumphousing

withcleanhydraulicuidthroughcasedrainhole.

2.ApplycleanpetroleumjellyorlightgreasetoanewO-ring(item1Figure53)

andpositiontheO-ringontothegearpumpange.

3.Alignthegearpumpshaftandslidethegearpumpintothetractionpump

coupler.

4.Securethegearpumptothepistonpumpwiththepreviouslyremoved

fasteners.

5.Removethecapsandplugsfromthehydraulicttingsandhydrauliclines

theninstallthehydrauliclinestothepistonpumpandthegearpump;referto

InstallingHydraulicHosesandTubes(O-RingFaceSealFitting)(page5–7).

Tightenthegearpumpsuctionhoseclampto10N∙m(90in-lb).

6.Primethehydraulicpump;refertoPrimingtheHydraulicPumps(page5–60).

HydraulicSystem:ServiceandRepairs

Page5–76

Groundsmaster

®

3200,3300and3310

19240SLRevA

Loading...

Loading...