FilteringtheClosed-loopTractionCircuit

Filteringofaclosed−loophydraulicsystemafteramajorcomponentfailure

(e.g.traction(piston)pumporwheelmotor)isrequiredtopreventdebrisfrom

transmittingthroughoutthesystem.Ifalteringtoolisnotused(toensurethat

thesystemisclean),repeatfailuresandsubsequentdamagetootherhydraulic

componentsinthesystemwilloccur.Toeffectivelyremovecontaminationfrom

theclosed−looptractioncircuit,useofaTorobidirectionalhighowhydraulic

lterandhydraulichosekitisrecommended;refertoHighFlowHydraulicFilter

Kit(page2–18).

1.Parkmachineonalevelsurface,lowerthecuttingunit(orattachment),set

thekeyswitchtotheOFFpositionandremovethekeyfromthekeyswitch.

2.ReadandadheretotheinformationprovidedinGeneralPrecautionsfor

RemovingandInstallingtheHydraulicSystemComponents(page5–52).

WARNING

ReviewandfollowtheJackingInstructions(page1–6)beforelifting

themachine.

3.Raisebothfrontwheelsfor2WDmachines,orall4wheelsfor4WDmachines

offtheoorandsupportthemachine.

4.Installthehydrauliclterdirectlyupstreamofthenewcomponenttoprevent

systemcontaminationfromenteringanddamagingthenewcomponent.

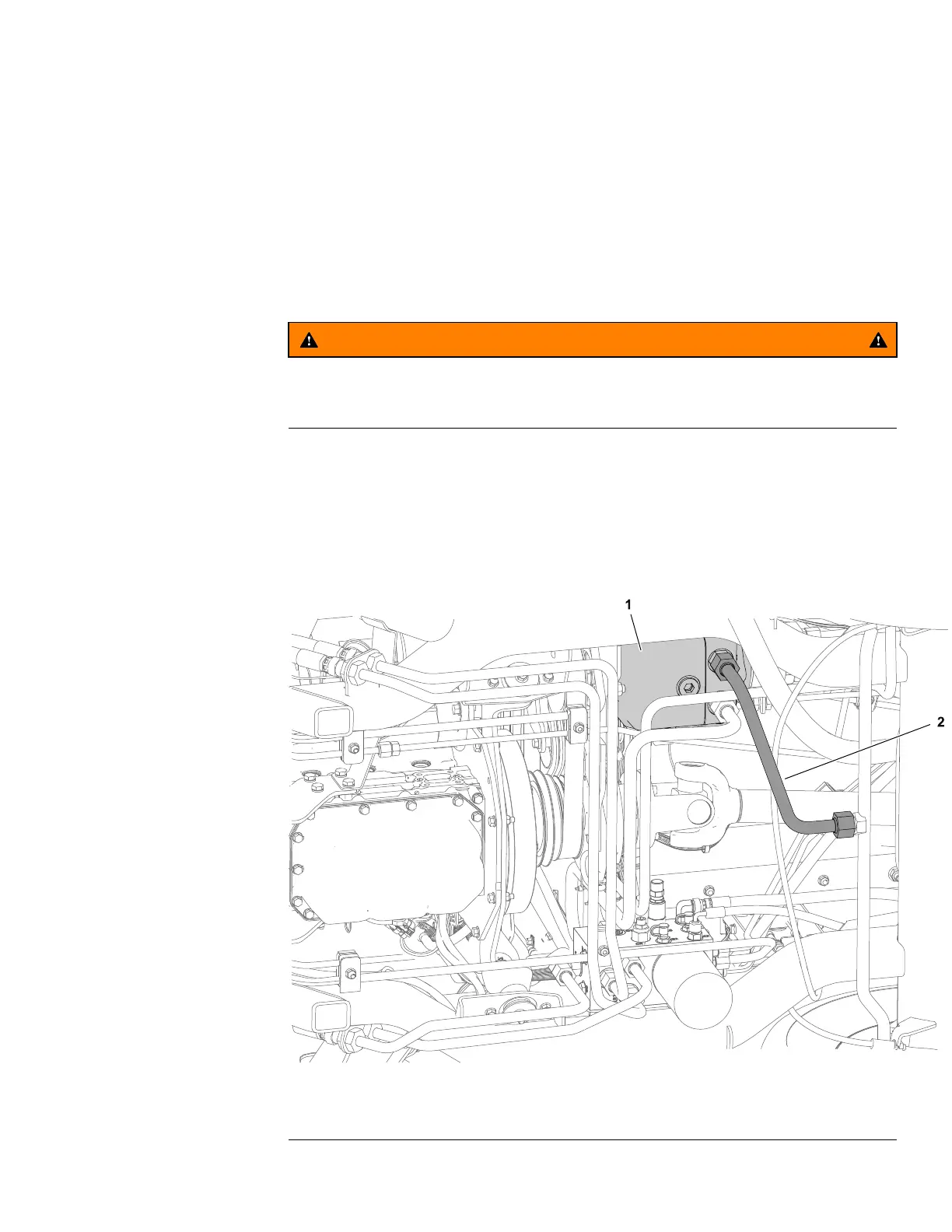

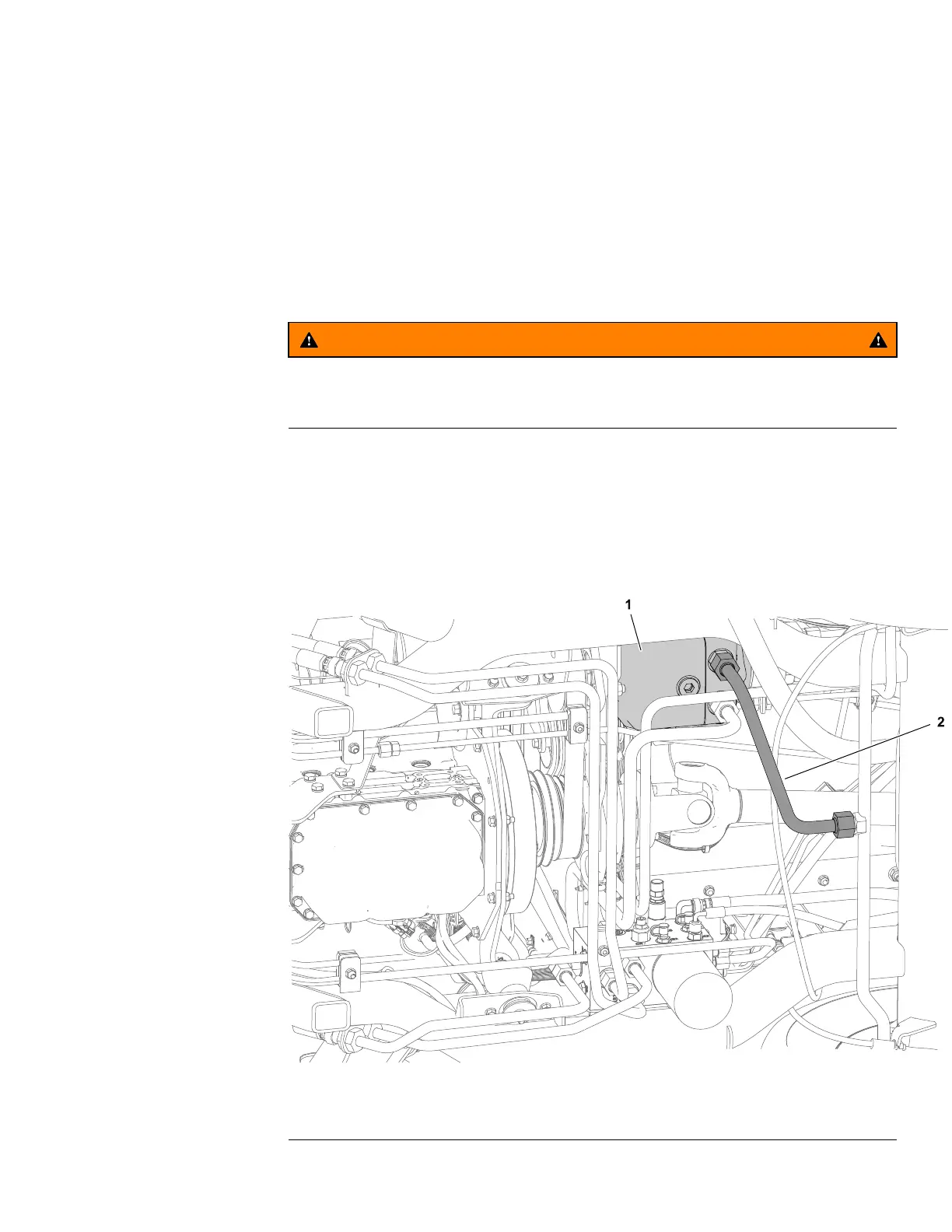

A.Ifthetraction(piston)pumporafrontwheelmotorwasreplaced,

thoroughlycleanbothendsofthehydraulictubeshowninFigure44,then

removethehydraulictubefromthemachine.

g299564

Figure44

1.Traction(piston)Pump

2.Hydraulictube

Groundsmaster

®

3200,3300and3310

Page5–57

HydraulicSystem:ServiceandRepairs

19240SLRevA

Loading...

Loading...