AdjustingtheTractionNeutralSwitch(continued)

IMPORTANT

Topreventdamagetothetractionneutralswitch,makesurethat

nothingcontactstheswitchfaceduringoperationoradjustment.Do

notscratchthefaceoftheneutralswitch.

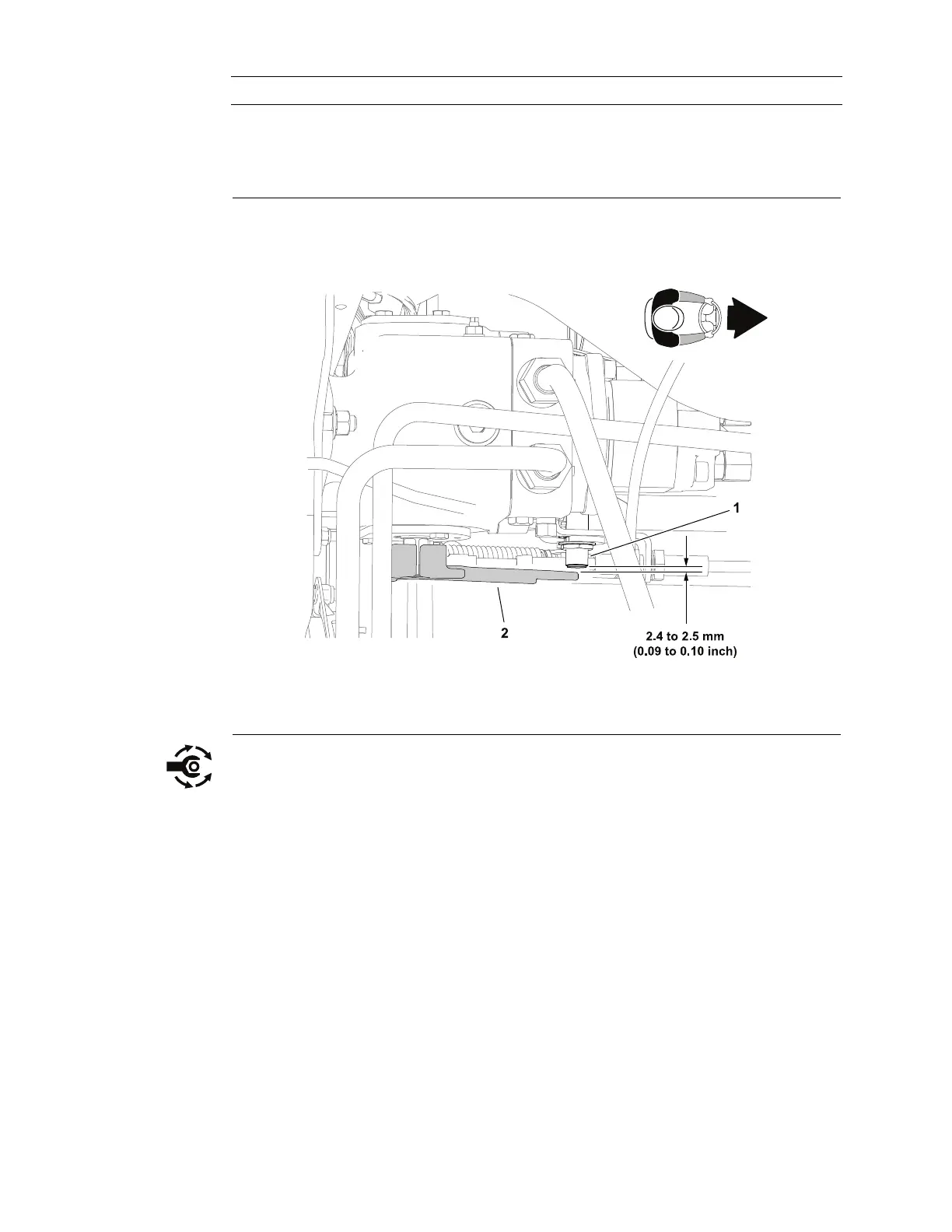

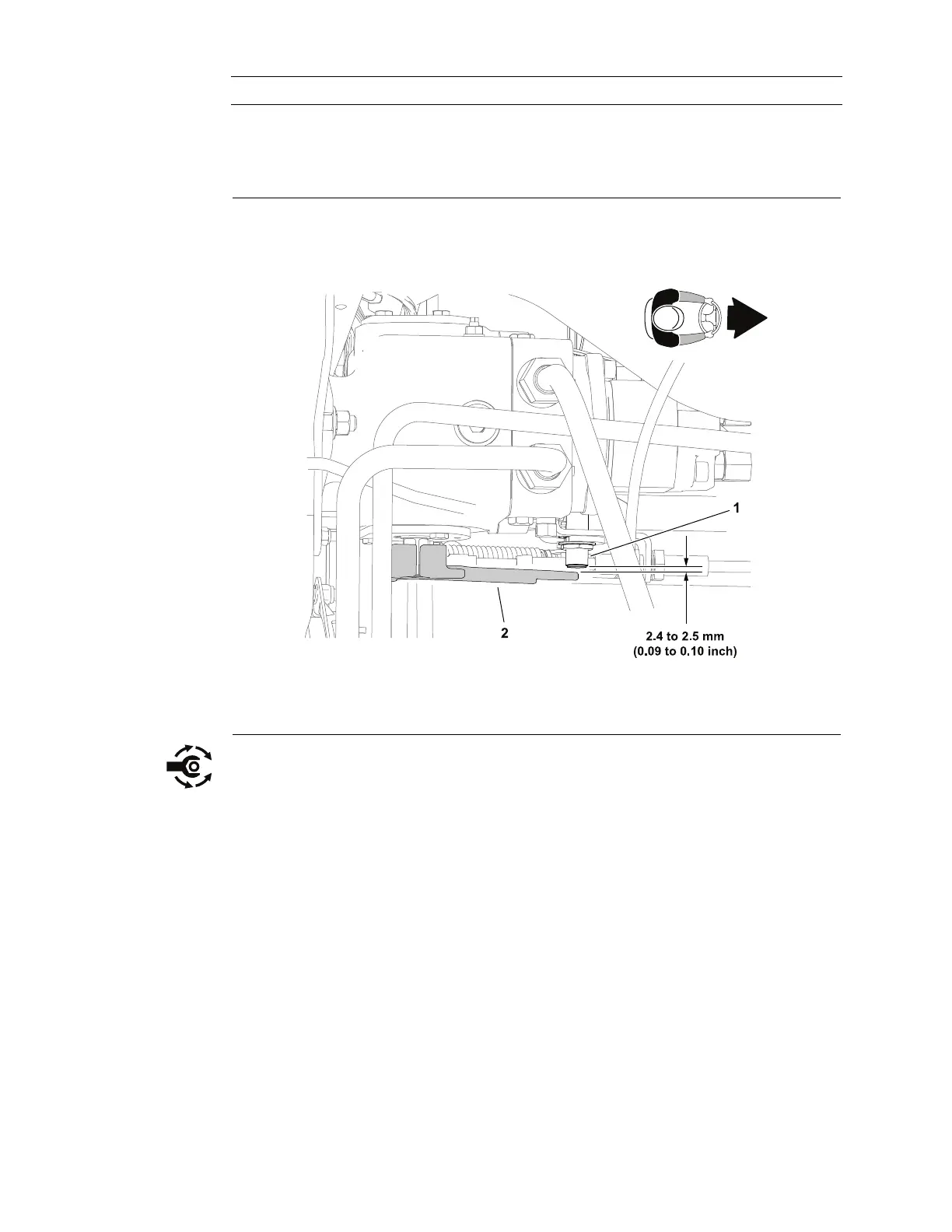

2.WhenthetractionleverisintheNEUTRALposition,theclearancebetweenthe

faceoftheneutralswitchandthepumplevershouldbefrom2.4to2.5mm

(0.09to0.10inch).

g301786

Figure89

1.Neutralswitch2.Pumplever

3.Iftheclearanceisincorrect,loosenthejamnutsthatsecureneutralswitch

tothebracket.Usethejamnutstomovetheswitchtothecorrectposition.

Tightenthejamnutsfrom18.4to22.4N·m(162to198in-lb).Re-checkthe

switchtoleverclearanceandadjustifnecessary.

4.Afteradjustingtheneutralswitch,usetheTDMdisplay/controllerscreento

verifythatneutralswitchandcircuitwiringarefunctioningcorrectly.

TestingtheTractionNeutralSwitch

ThetractionneutralswitchanditscircuitwiringcanbetestedusingtheTDM

display/controllermaininformationscreens(neutralicon);refertoUsingthe

TDMDisplay/ControllerScreensforTroubleshooting(page3–12).Iftesting

determinesthattheswitchandcircuitwiringarenotfunctioningcorrectly,

proceedwiththefollowingtestprocedure:

1.Parkthemachineonalevelsurface,lowerthecuttingunit(orattachment),

engagetheparkingbrake,setthekeyswitchtotheOFFpositionandremove

thekeyfromthekeyswitch.

2.Ensurethatthetractionneutralswitchiscorrectlyadjusted;refertoAdjusting

theTractionNeutralSwitch(page6–29).

ElectricalSystem:TestingtheElectricalComponents

Page6–30

Groundsmaster

®

3200,3300and3310

19240SLRevA

Loading...

Loading...