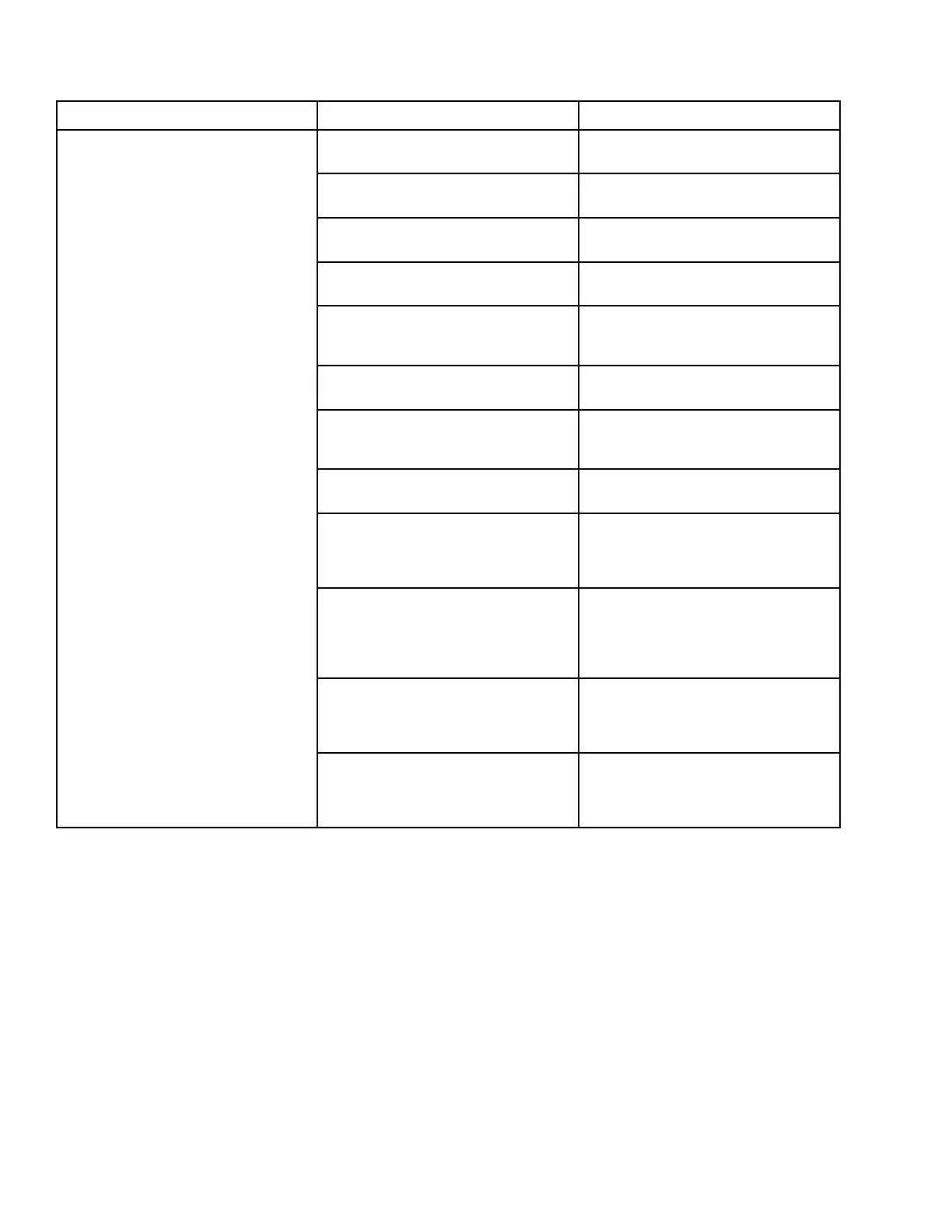

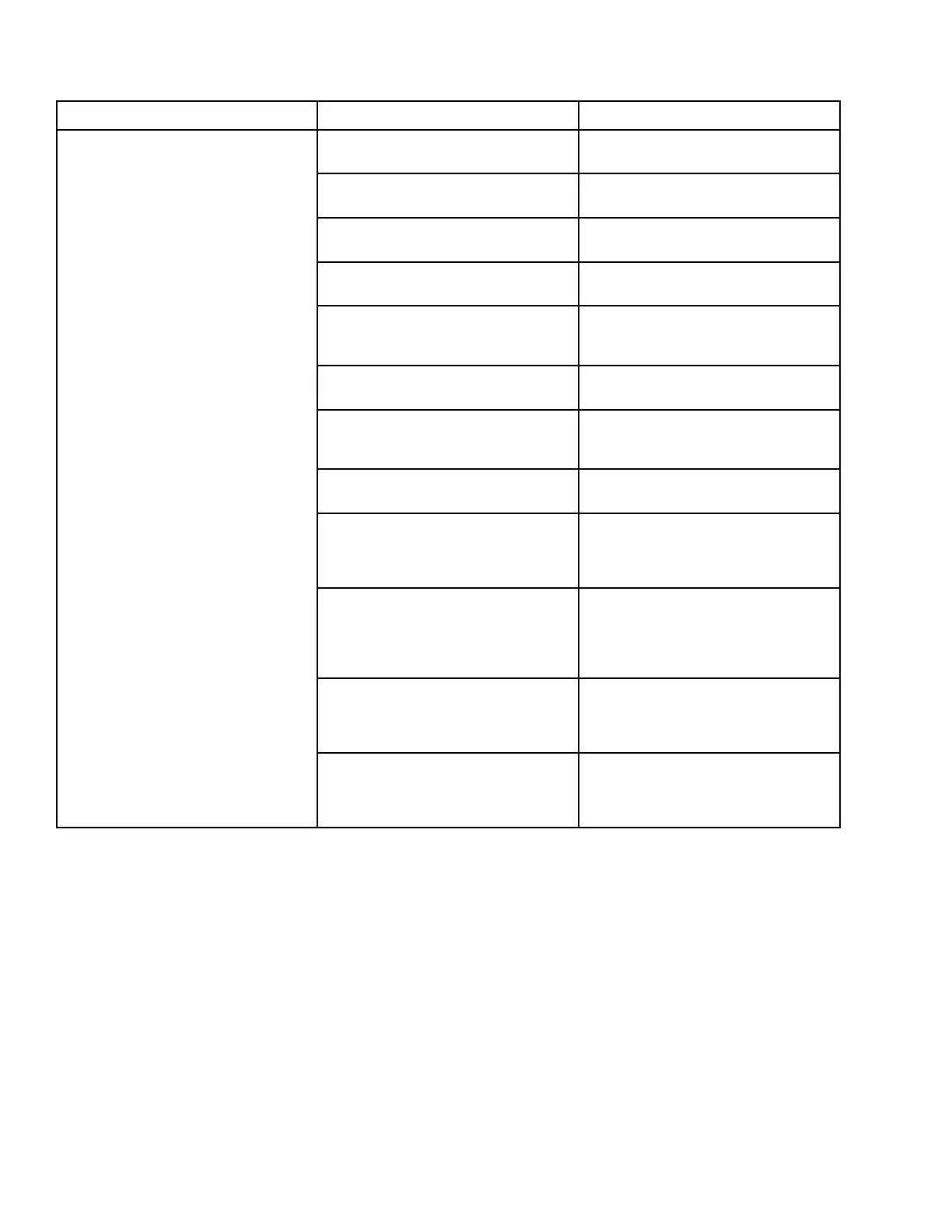

GeneralHydraulicSystemProblems(continued)

Problem

PossibleCauseCorrectiveAction

Thetractionsystempressureishigh

duetoloadordraggingbrakes.

Inspectbrakeoperationandserviceor

adjustifnecessary.

Thehydraulicuidlevelinthehydraulic

tankislow.

Adjustthehydraulicuidlevel.

Thesuctionlterorsuctionlineis

damaged,loose,orclogged.

Secure,cleanorreplacethesuction

lterorsuctionline.

Thehydraulicuidiscontaminatedor

theuidviscosityistoolight.

Replacethehydraulicuid.

Note:Refertothetractionunit

Operator’sManualforhydraulicuid

specications.

Thehydraulicuidcoolerisdamaged

orplugged.

Repairorreplacethehydraulicuid

cooler.

Theuidcoolerairowisobstructed.Verifycoolingfanoperationandremove

debrisfrominandaroundtheuid

cooler.

Thetractionpumpbypassvalveisopen

ordamaged.

Closeorreplacethetractionpump

bypassvalve.

Thechargepressureislow(steering

andliftcircuitperformanceisalso

affected).

Verifychargepressure;refertoT esting

theTractionCircuit–ChargePressure

intheHydraulicSystemchapterofthis

manual.

Thetractionpumpiswornordamaged.

Verifytractionpumpoperation;refer

toTestingtheTractionCircuit–Piston

(traction)Pump(P1)FlowandRelief

PressureT estintheHydraulicSystem

chapterofthismanual.

Thewheelmotor(s)iswornor

damaged.

Verifywheelmotoroperation;referto

TestingtheTractionCircuit–Wheel

MotorEfciencyintheHydraulic

Systemchapterofthismanual.

Thehydraulicsystemoperateshot

(exceeds95°C(203°F).

Note:Ifatractioncircuitcomponent

hasinternalwearordamage,it

ispossiblethattheothertraction

componentsarealsodamaged.

Troubleshooting:GeneralHydraulicSystemProblems

Page3–16

Groundsmaster

®

3200,3300and3310

19240SLRevA

Loading...

Loading...