n

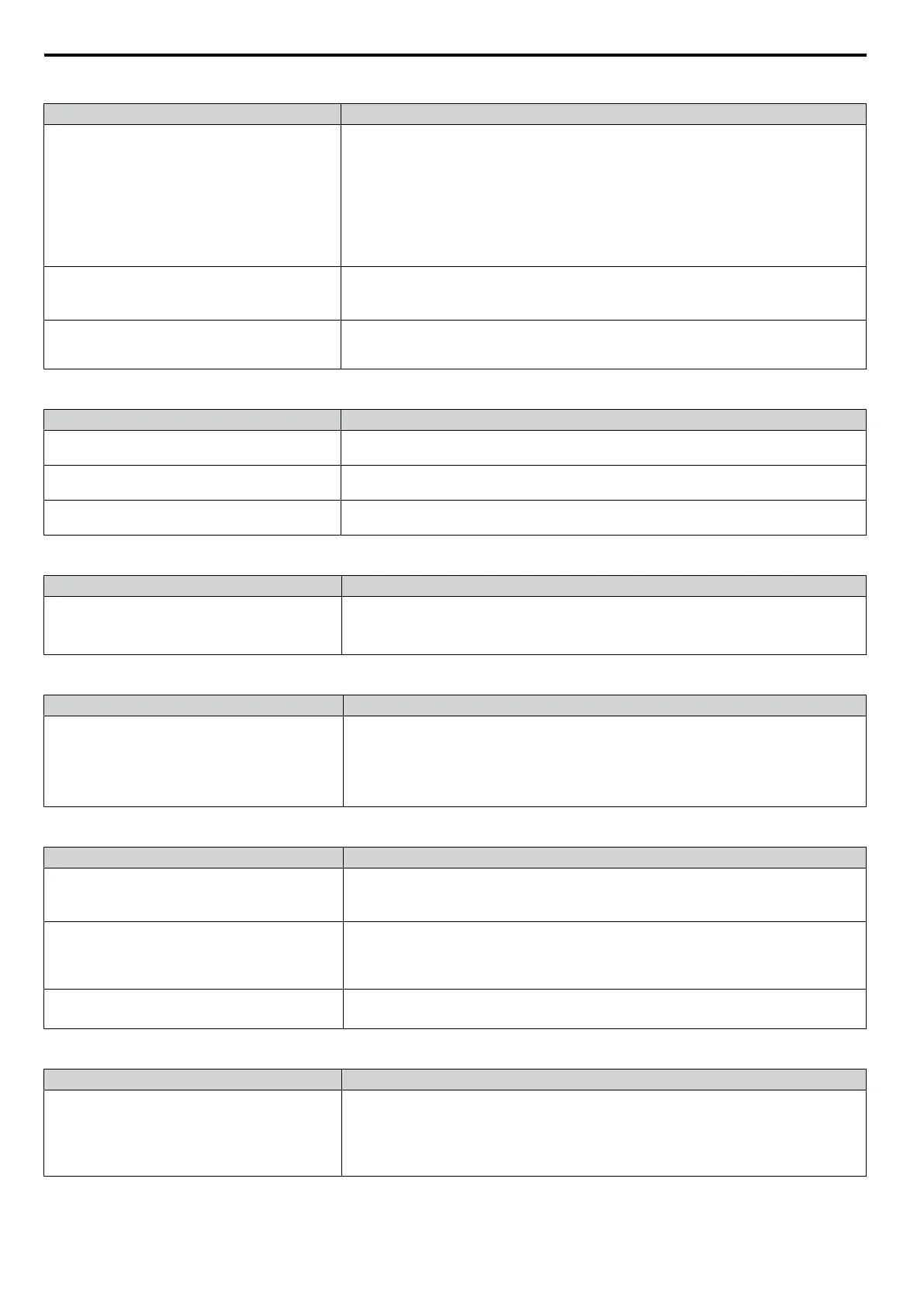

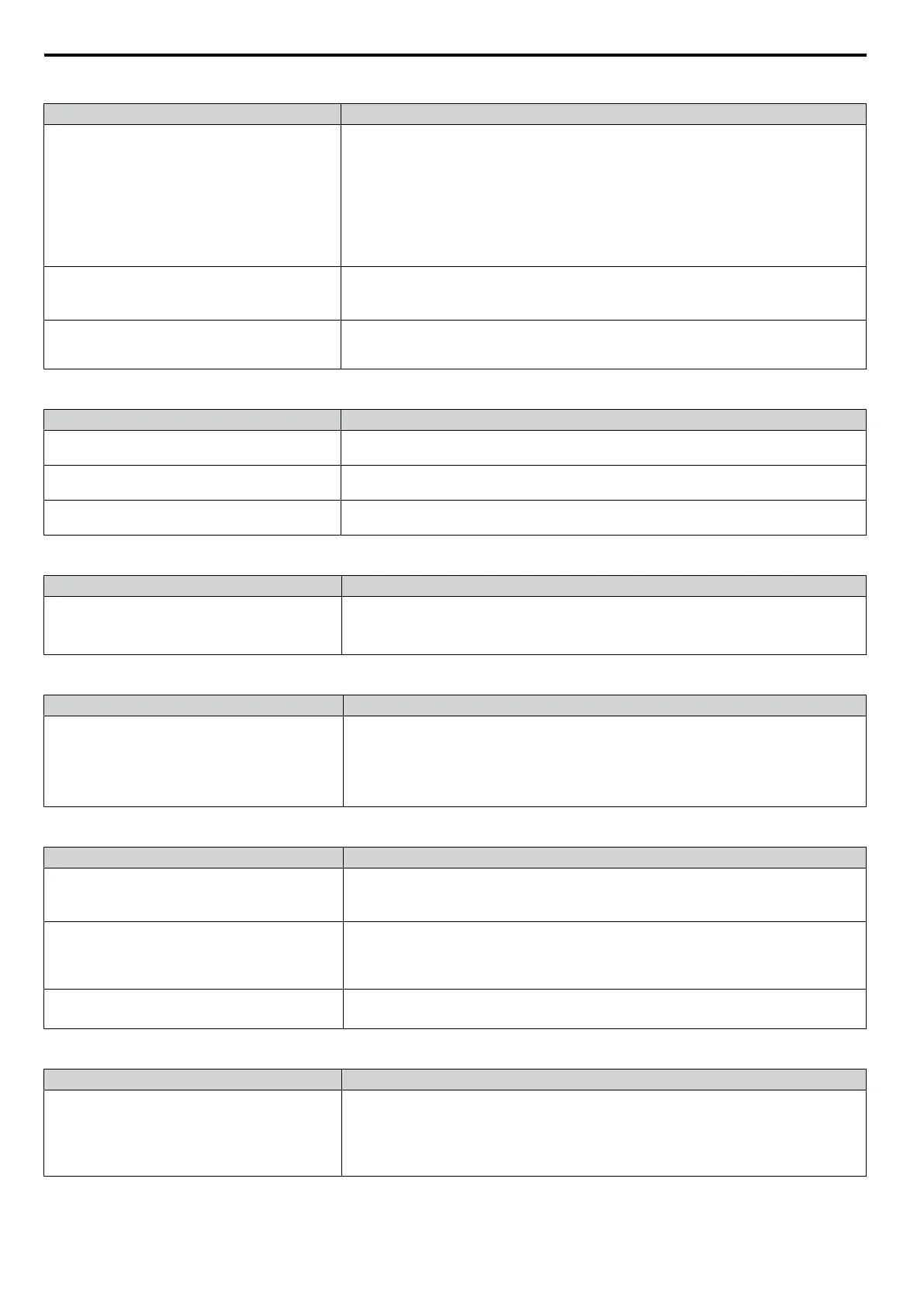

PID output fault

Cause Possible Solutions

No PID feedback input.

• Check the multi-function analog input terminal settings.

• Set multi-function analog input terminal A1 or A2 for PID feedback (H3-02 or H3-10 =

“B”).

• A signal input to the terminal selection for PID feedback is necessary.

• Check the connection of the feedback signal.

• Check the various PID-related parameter settings.

• No PID feedback input to the terminal causes the value detected to be 0, causing a PID fault

and the drive to operate at max frequency.

The level of detection and the target value do not

correspond with each other.

• PID control keeps the difference between target and detection values at 0. Set the input level

for the values relative to one another.

• Use analog input gains H3-03/11 to adjust PID target and feedback signal scaling.

Reverse drive output frequency and speed detection.

When output frequency rises, the sensor detects a

speed decrease.

Set PID output for reverse characteristics (b5-09 = “1”).

n

Insufficient Motor Torque

Cause Possible Solutions

Auto-Tuning has not yet been performed (required

for OLV Control).

Perform Auto-Tuning.

The control mode was changed after performing

Auto-Tuning.

Perform Auto-Tuning again.

Only Line-to-Line Resistance Auto-Tuning was

performed.

Perform Rotational Auto-Tuning.

n

Motor Rotates After the Drive Output is Shut Off

Cause Possible Solutions

Low DC Injection Braking and the drive cannot

decelerate properly.

• Adjust the DC Injection braking settings.

• Increase the value of b2-02 (DC Injection Braking Current).

• Increase the b2-04 (DC Injection Braking Time at Stop).

n

ov or Speed Loss Occurs When Starting into a Rotating Load

Cause Possible Solutions

The load is already rotating when the drive is trying

to start it.

• Stop the motor using DC Injection braking. Restart the motor.

• Increase the value of b2-03 (DC Injection Braking Time at start).

• Enable Speed Search at start (b3-01 = “1”).

•

Set a multi-function input terminal for external Speed Search command (H1-oo=“61” or

“62” during restart).

n

Output Frequency is not as High as Frequency Reference

Cause Possible Solutions

Frequency reference is set within the range of the

Jump Frequency.

• Adjust the parameters used for the Jump Frequency function (d3-01, d3-02, d3-03).

• Enabling the Jump Frequency prevents the drive from

outputting the frequencies specified

in the Jump Frequency range.

Upper limit for the frequency reference has been

exceeded.

• Set the maximum output frequency and the upper limit for the frequency reference to more

appropriate values (E1-04, d2-01).

• The following calculation yields

the upper value for the output frequency = E1-04 x d2-01 /

100

Large load triggered Stall Prevention function during

acceleration.

• Reduce the load.

• Adjust the Stall Prevention level during acceleration (L3-02).

n

Buzzing Sound from Motor at 2 kHz

Cause Possible Solutions

Exceeded 110% of the rated output current of the

drive while operating at low speeds.

• If the output current rises too high at low speeds, the carrier frequency automatically reduces

and causes a whining or buzzing sound.

• If the sound is coming from the motor, disable carrier frequency derating (L8-38 = “0”).

• Disabling the automatic carrier frequency

derating increases the chances of an overload fault

(oL2). Switch to a larger capacity motor if oL2 faults occur too frequently.

6.9 Troubleshooting without Fault Display

286

YASKAWA ELECTRIC SIEP C710606 16C YASKAWA AC Drive – V1000 Technical Manual

Loading...

Loading...