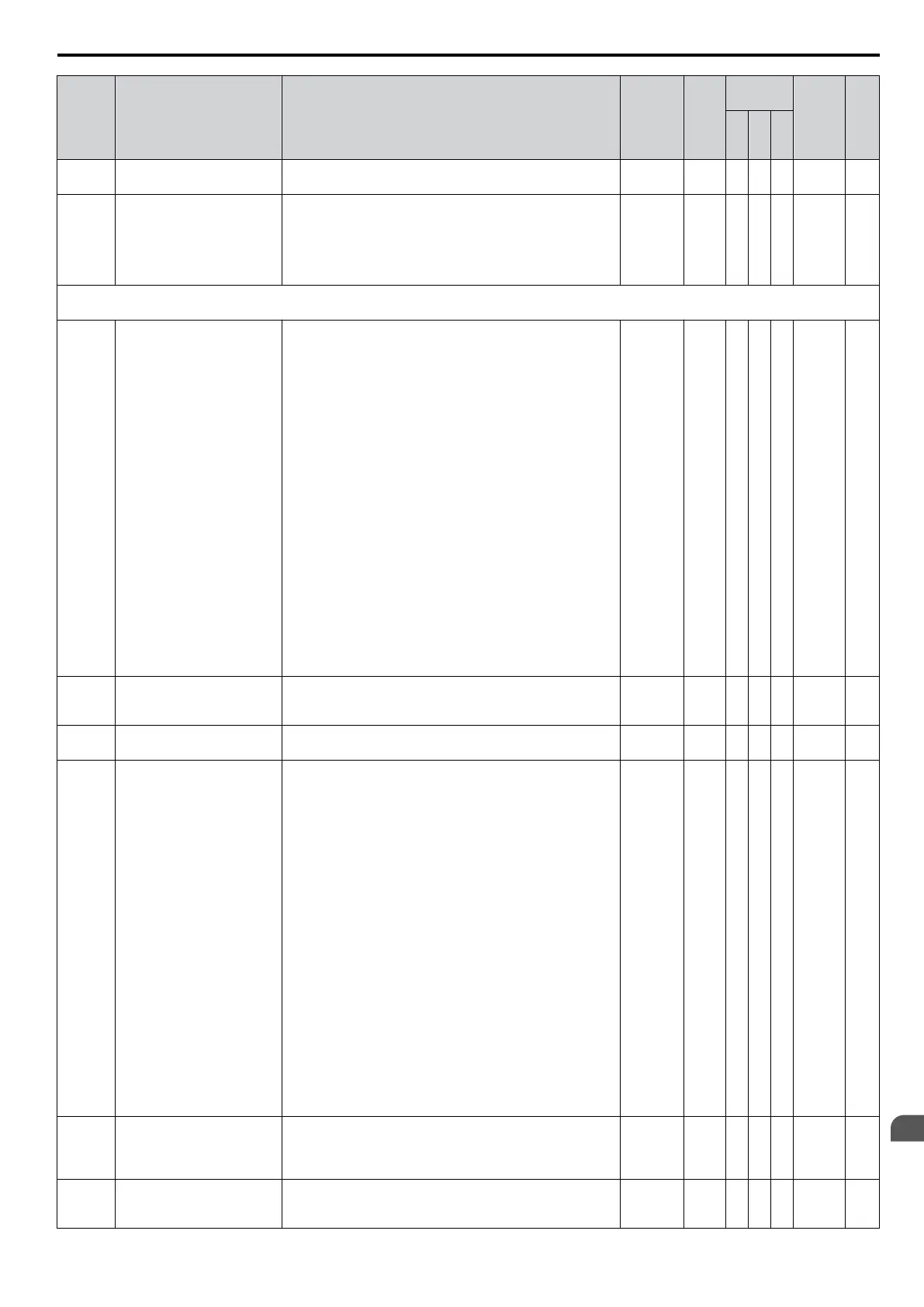

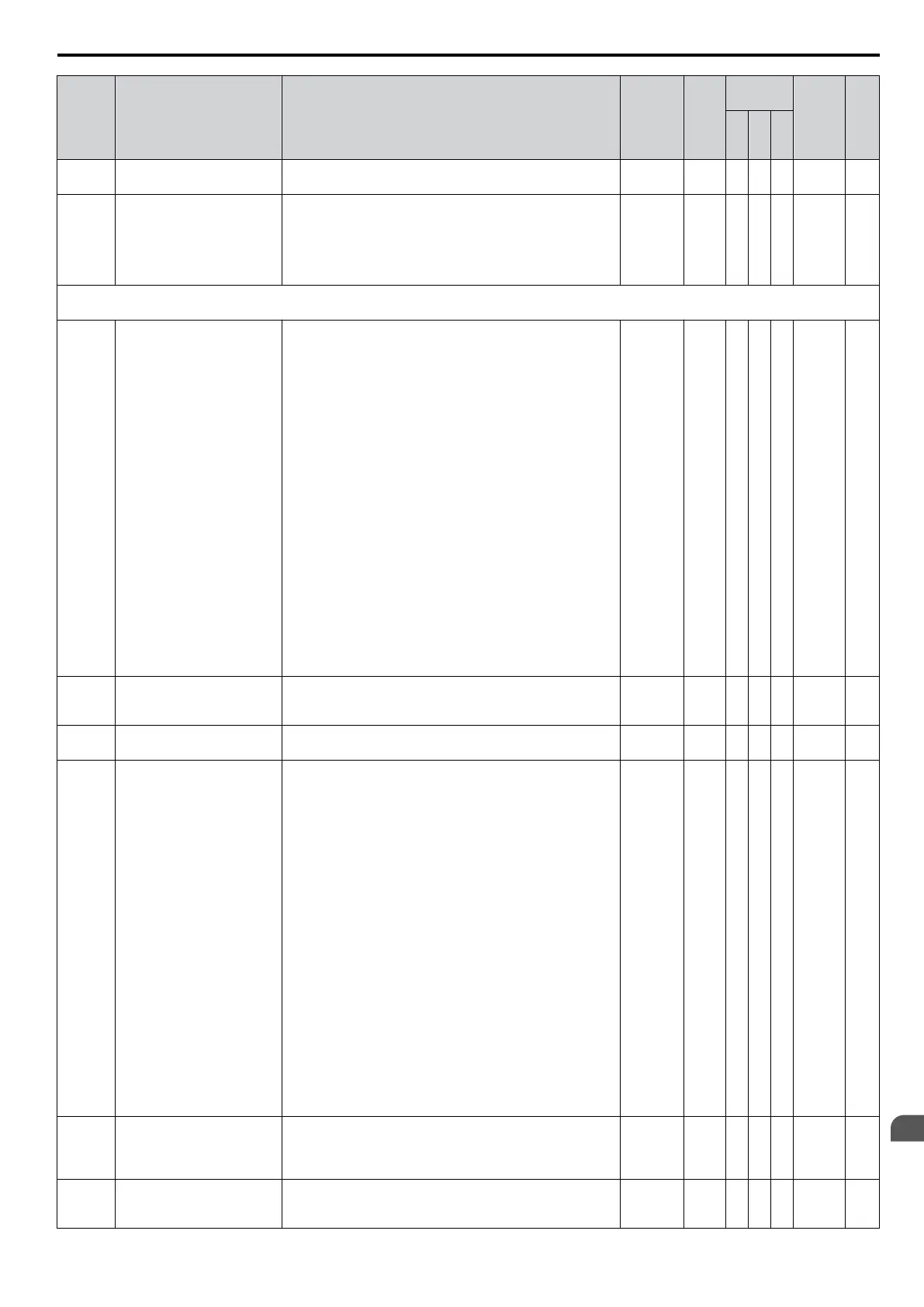

No. Name Description Range Def.

Control

Mode

Addr.

Hex

Pg.

V/

f

O

L

V

P

M

L5-04 Fault Reset Interval Time

Sets the amount of time to wait between performing fault

restarts. Enabled when L5-05 is set to 1.

0.5 to

600.0 s

10.0 s A A A 46C 220

L5-05

Fault Reset Operation

Selection

Selects the method of incrementing the restart counter.

0: Continuously attempt to restart and increment counter

after successful restart (same as Varispeed VS616-F7/G7)

1: Attempt to restart with the interval time set in L5-04.

Every trial increments the counter. (same as Varispeed

VS606-V7)

0, 1 0 A A A 467 220

L6: Overtorque Detection

Use L6 parameters to configure overtorque detection.

L6-01

Torque Detection Selection

1

Selects the overtorque/undertorque operation. overtorque

and undertorque are determined by the settings in parameters

L6-02 and L6-03. The multi-function output settings (H2-

oo= B and 17) are also active if programmed.

0: Disabled

1: oL3 at Speed Agree - Alarm (overtorque detection only

active during Speed Agree and operation continues after

detection).

2: oL3 at RUN - Alarm (overtorque detection is always

active and operation continues after detection).

3: oL3 at Speed Agree - Fault (overtorque detection only

active during Speed Agree and drive output will shut down

on an oL3 fault).

4: oL3 at RUN - Fault (overtorque detection is always active

and drive output will shut down on an oL3 fault).

5: UL3 at Speed Agree - Alarm (undertorque detection is

only active during Speed Agree and operation continues

after detection).

6: UL3 at RUN - Alarm (undertorque detection is always

active and operation continues after detection).

7: UL3 at Speed Agree - Fault (undertorque detection only

active during Speed Agree and drive output will shut down

on an oL3 fault).

8: UL3 at RUN - Fault (undertorque detection is always

active and drive output will shut down on an oL3 fault).

0 to 8 0 A A A 4A1 220

L6-02 Torque Detection Level 1

Sets the overtorque/undertorque detection level. 100% is

equal to the motor rated current in V/f

Control and the motor

rated torque in Open Loop Vector Control.

0 to 300 150% A A A 4A2 222

L6-03 Torque Detection Time 1

Sets the length of time an overtorque/undertorque condition

must exist before Torque Detection 1 is triggered.

0.0 to

10.0

0.1 s A A A 4A3 222

L6-04

Torque Detection Selection

2

Sets the response to an overtorque/undertorque condition.

overtorque and undertorque are determined by the settings

in parameters L6-05 and L6-06. The multi-function output

settings (H2-oo = 18 and 19).

0: Disabled

1: oL4 at Speed Agree - Alarm (overtorque Detection only

active during Speed Agree and Operation continues after

detection).

2: oL4 at RUN - Alarm (overtorque Detection is always

active and operation continues after detection).

3: oL4 at Speed Agree - Fault (overtorque Detection only

active during Speed Agree and drive output will shut down

on an oL4 fault).

4: oL4 at RUN - Fault (overtorque Detection is always active

and drive output will shut down on an oL4 fault).

5: UL4 at Speed Agree - Alarm (undertorque Detection is

only active during Speed Agree and operation continues

after detection).

6: UL4 at RUN - Alarm (undertorque Detection is always

active and operation continues after detection).

7: UL4 at Speed Agree - Fault (undertorque Detection only

active during Speed Agree and drive output will shut down

on an oL4 fault).

8: UL4 at RUN - Fault (undertorque Detection is always

active and drive output will shut down on an oL4 fault).

0 to 8 0 A A A 4A4 221

L6-05 Torque Detection Level 2

Sets the overtorque/undertorque detection level. 100% is

equal to the motor rated current in V/f Control or PM OLV

and equal to the motor rated torque in Open Loop Vector

Control.

0 to 300 150% A A A 4A5 222

L6-06 Torque Detection Time 2

Sets the length of time an overtorque/undertorque condition

must exist before torque detection 2 is recognized by the

drive.

0.0 to

10.0

0.1 s A A A 4A6 222

B.2 Parameter Table

YASKAWA ELECTRIC SIEP C710606 16C YASKAWA AC Drive – V1000 Technical Manual

361

B

Parameter List

Loading...

Loading...