Parameter

structure

Keypad and

display

Parameter

x.00

Parameter

description format

Advanced parameter

descriptions

Macros

Serial comms

protocol

Electronic

nameplate

Performance

Feature look-

up table

Menu 11

Unidrive SP Advanced User Guide 191

Issue Number: 7 www.controltechniques.com

The drive Onboard PLC program status parameter indicates to the user the actual state of the drive Onboard PLC program. (not fitted / running /

stopped / tripped.)

The drive Onboard PLC programming events parameter holds the number of times a Onboard PLC program download has taken place and is 0 on

dispatch from the factory. If the drive Onboard PLC programming events is greater than the maximum value which may be represented by this

parameter the value will be clipped to the maximum value. This parameter is not altered when defaults are loaded.

The Onboard PLC program maximum scan time parameter gives the longest scan time within the last ten scans of the drive Onboard PLC program.

If the scan time is greater than the maximum value which may be represented by this parameter the value will be clipped to the maximum value.

The drive Onboard PLC program first run parameter is set for the duration of the first ladder diagram scan from the ladder diagram stopped state. This

enables the user to perform any required initialisation every time the ladder diagram is run. This parameter is set every time the ladder is stopped.

Value Description

0 Halt the drive Onboard PLC program.

1

Run the drive Onboard PLC program (if fitted). Any out-of-range parameter writes attempted will be clipped to the

maximum / minimum values valid for that parameter before being written.

2 Run the drive Onboard PLC program (if fitted). Any out-of-range parameter writes attempted will cause a drive trip.

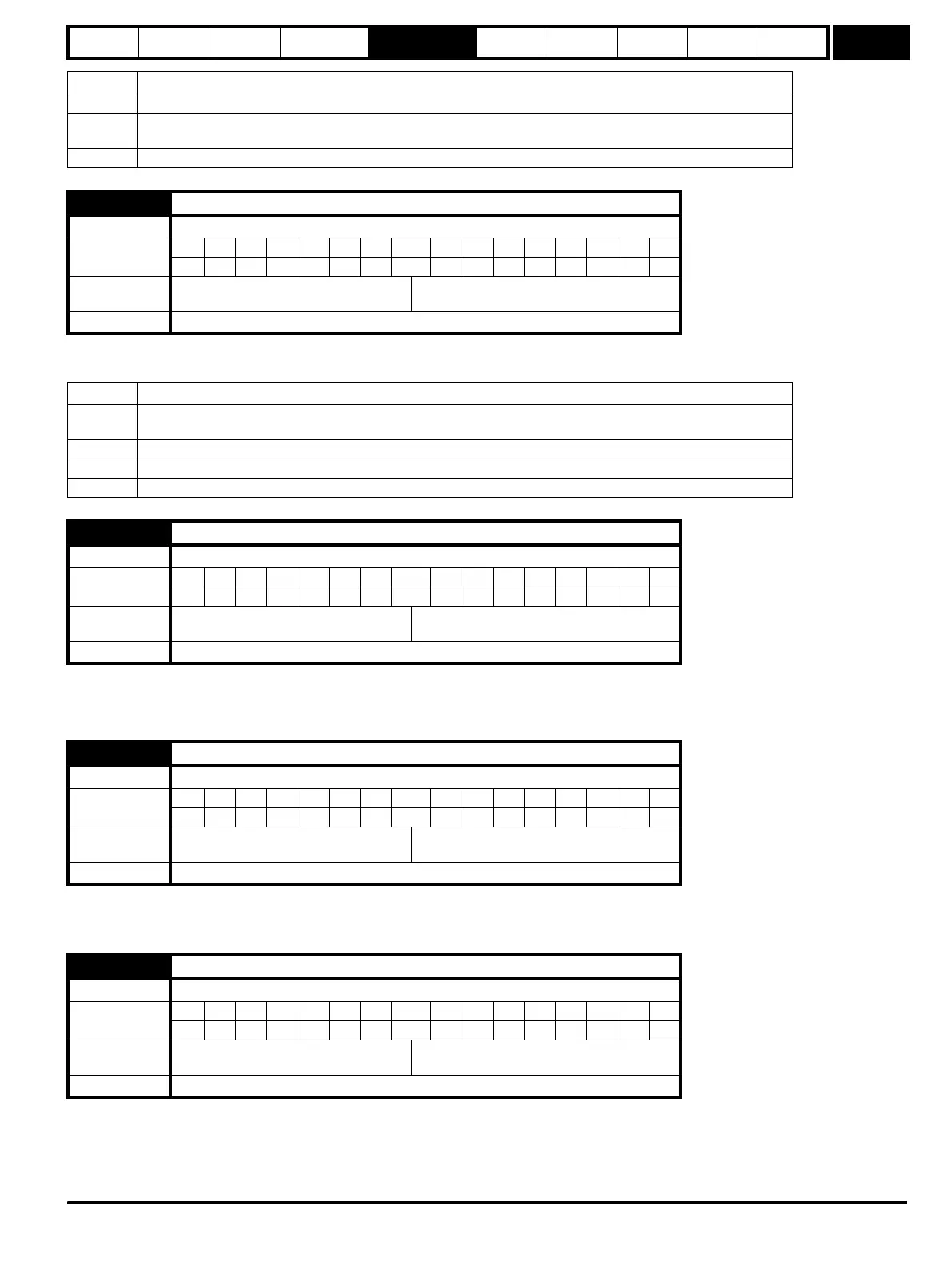

11.48 Drive Onboard PLC program status

Drive modes Open-loop, Closed-loop vector, Servo, Regen

Coding

Bit SP FI DE Txt VM DP ND RA NC NV PT US RW BU PS

111

Range

Open-loop, Closed-loop vector, Servo,

Regen

-128 to +127

Update rate Background write

Value Description

-n

Onboard PLC program caused a drive trip due to an error condition while running rung n. Note that the rung

number is shown on the display as a negative number.

0 Onboard PLC program is not fitted.

1 Onboard PLC program is fitted but stopped.

2 Onboard PLC program is fitted and running.

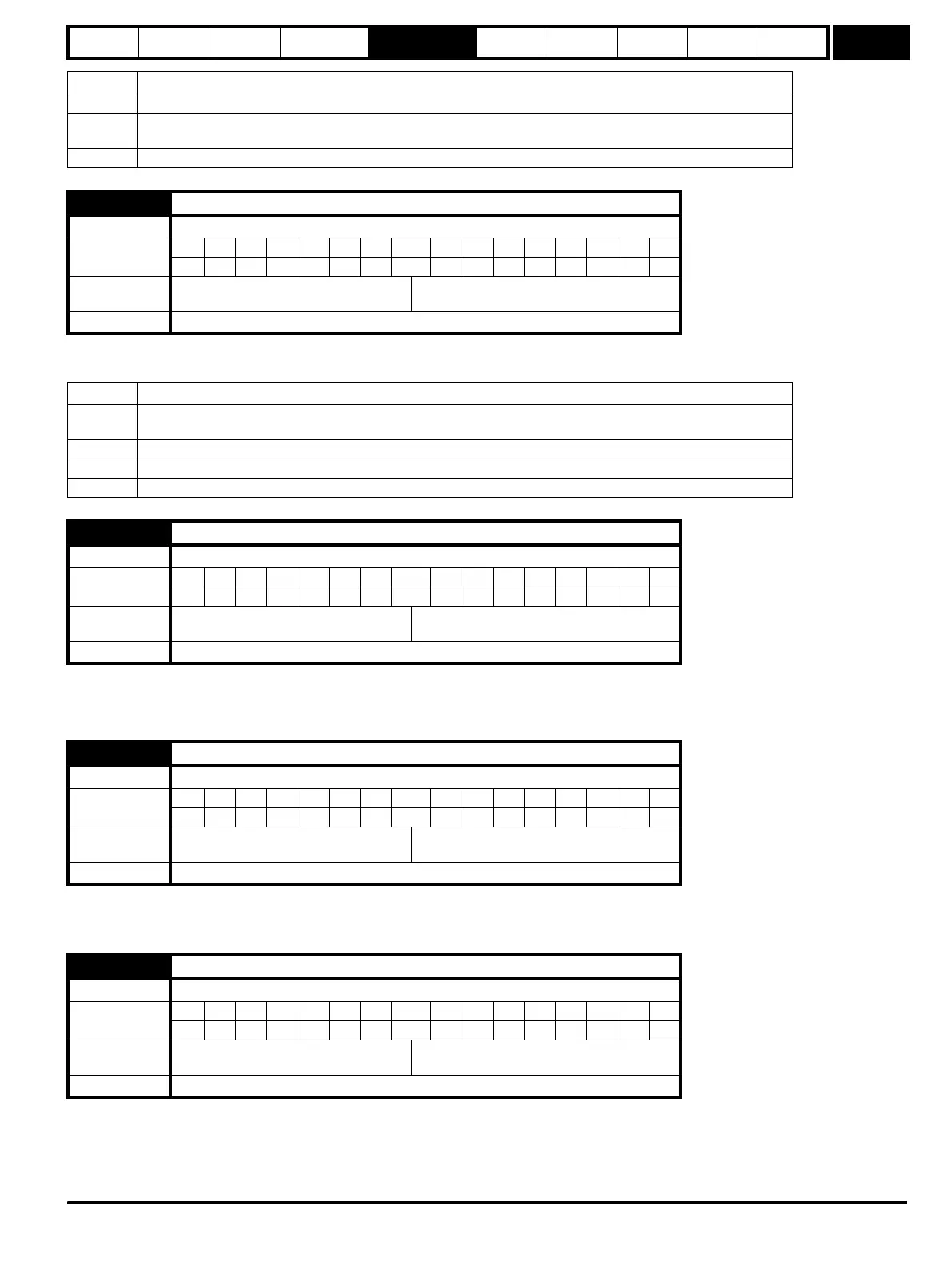

11.49 Drive Onboard PLC programming events

Drive modes Open-loop, Closed-loop vector, Servo, Regen

Coding

Bit SP FI DE Txt VM DP ND RA NC NV PT US RW BU PS

111 11

Range

Open-loop, Closed-loop vector, Servo,

Regen

0 to 65,535

Update rate Background write

11.50 Drive Onboard PLC program maximum scan time

Drive modes Open-loop, Closed-loop vector, Servo, Regen

Coding

Bit SP FI DE Txt VM DP ND RA NC NV PT US RW BU PS

111 1

Range

Open-loop, Closed-loop vector, Servo,

Regen

0 to 65,535 ms

Update rate Onboard PLC program execution period

11.51 Drive Onboard PLC program first run

Drive modes Open-loop, Closed-loop vector, Servo, Regen

Coding

Bit SP FI DE Txt VM DP ND RA NC NV PT US RW BU PS

1111

Range

Open-loop, Closed-loop vector, Servo,

Regen

0 or 1

Update rate Onboard PLC program execution period

http://nicontrols.com

Loading...

Loading...