Chapter 11 Motion Control Instructions

11-175

CombineMode is set to 1

=

= Position variation of Master axis1 ×

GearRatioNumeratorM1

GearRatioDenominatorM1

−

Position Variation of Master axis2 ×

GearRatioNumeratorM2

GearRatioDenominatorM2

The master gear ratio numerator and denominator are the factors to adjust the position variations

of two master axes. See the formula above.

MasterValueSource can be set to 0 (command position) and 1 (actual position) so as to specify the

source of the position variation. If the value is set to 0, add up the master axis command position

variations. If the value is set to 1, subtract one master axis actual position variation from another

master axis actual position variation.

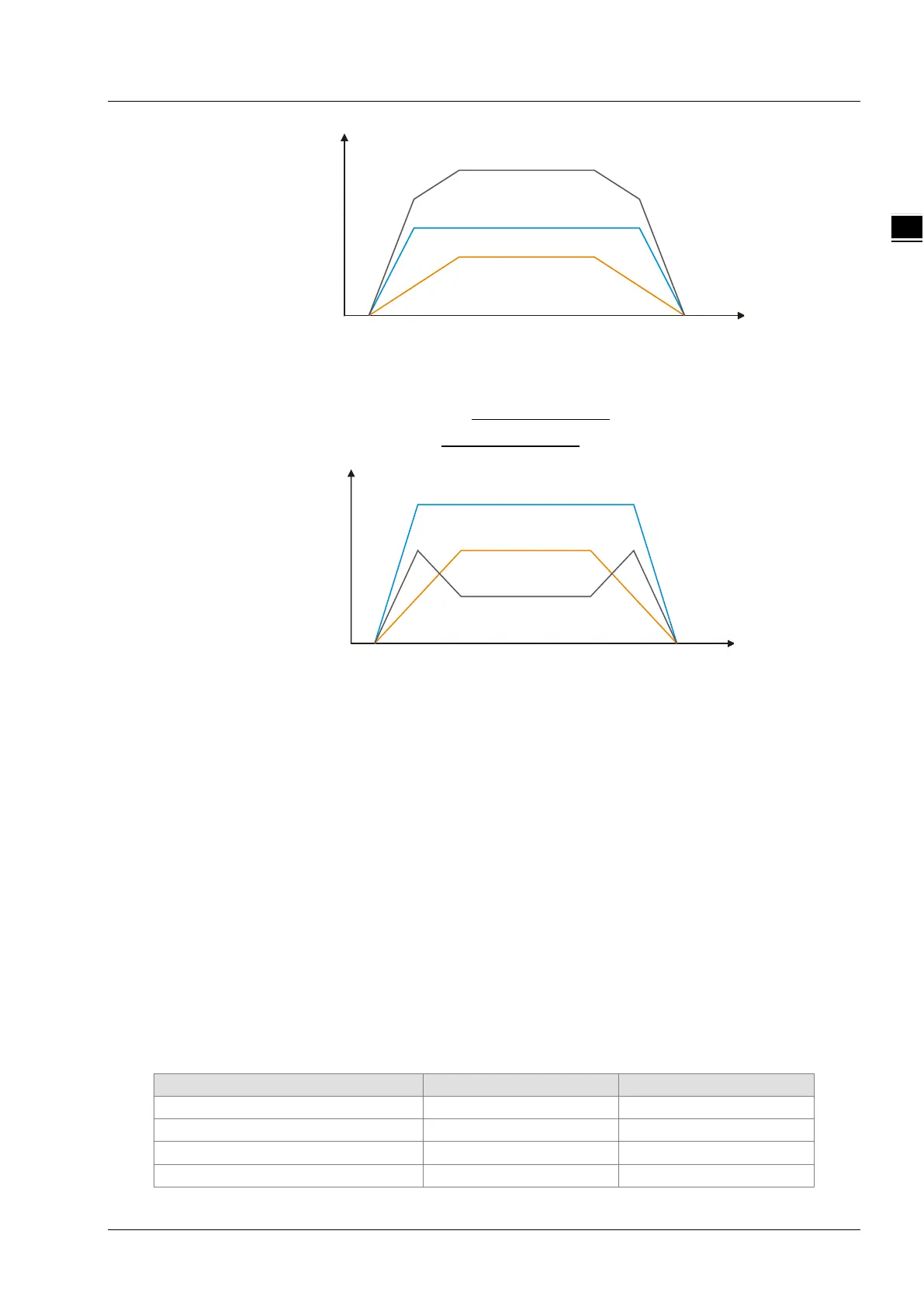

The Acc, Dec and Jerk indicate that the master axis has been in motion before the instruction is

executed. If the instruction is executed at the moment, the slave axis will speed up or down

according to the set acceleration, deceleration and jerk so as to realize the synchronization with the

master position variations. When the synchronization is achieved, InSync is TRUE and the

instruction execution is completed.

Use other motion instruction (such as MC_Stop instruction) for the control over the slave axis so as

to end the master-slave axis relationship in the instruction. Set the value of BufferMode of other

motion instruction which has the Buffermode parameter to 0 in order to abort the

MC_CombineAxes instruction and disconnect the master-slave axis relationship.

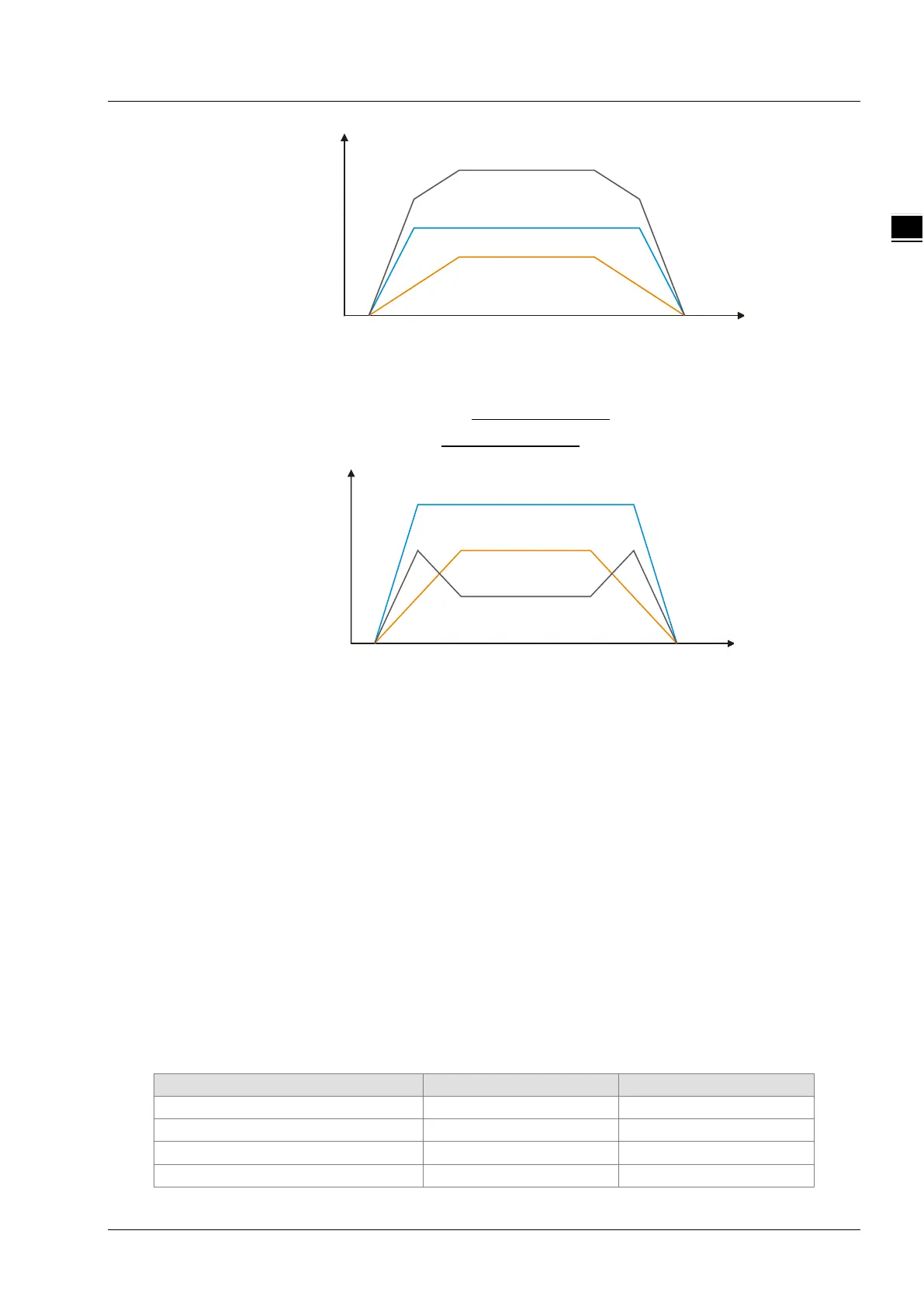

If the master axis gear ratio is to be switched during the motion, use another MC_CombineAxes

instruction to abort the MC_CombineAxes instruction which is being executed.

Programming Example

The example of executing the MC_CombineAxes instruction is described as below.

1. The variable table and program

Slave axis

Master a xis 1

Master a xis 2

Velocity

Time

Master a xis 1

Master a xis 2

Slave axis

Velocity

Time

Loading...

Loading...