Chapter 11 Motion Control Instructions

11-239

Introduction to Cam Curve with Rotary Cut Function

The cam curve with the rotary cut function could be divided into the SYNC area and adjustment area.

SYNC area: Feed axis and rotary-cut axis make the motion at a fixed speed ratio (Linear speed of the

knife is usually equal to that of the cut surface), and material cutting takes place in SYNC

area.

Adjustment area: Due to different cutting length, positioning need be adjusted accordingly.

Adjustment area can be in the following three situations based on various cutting

length.

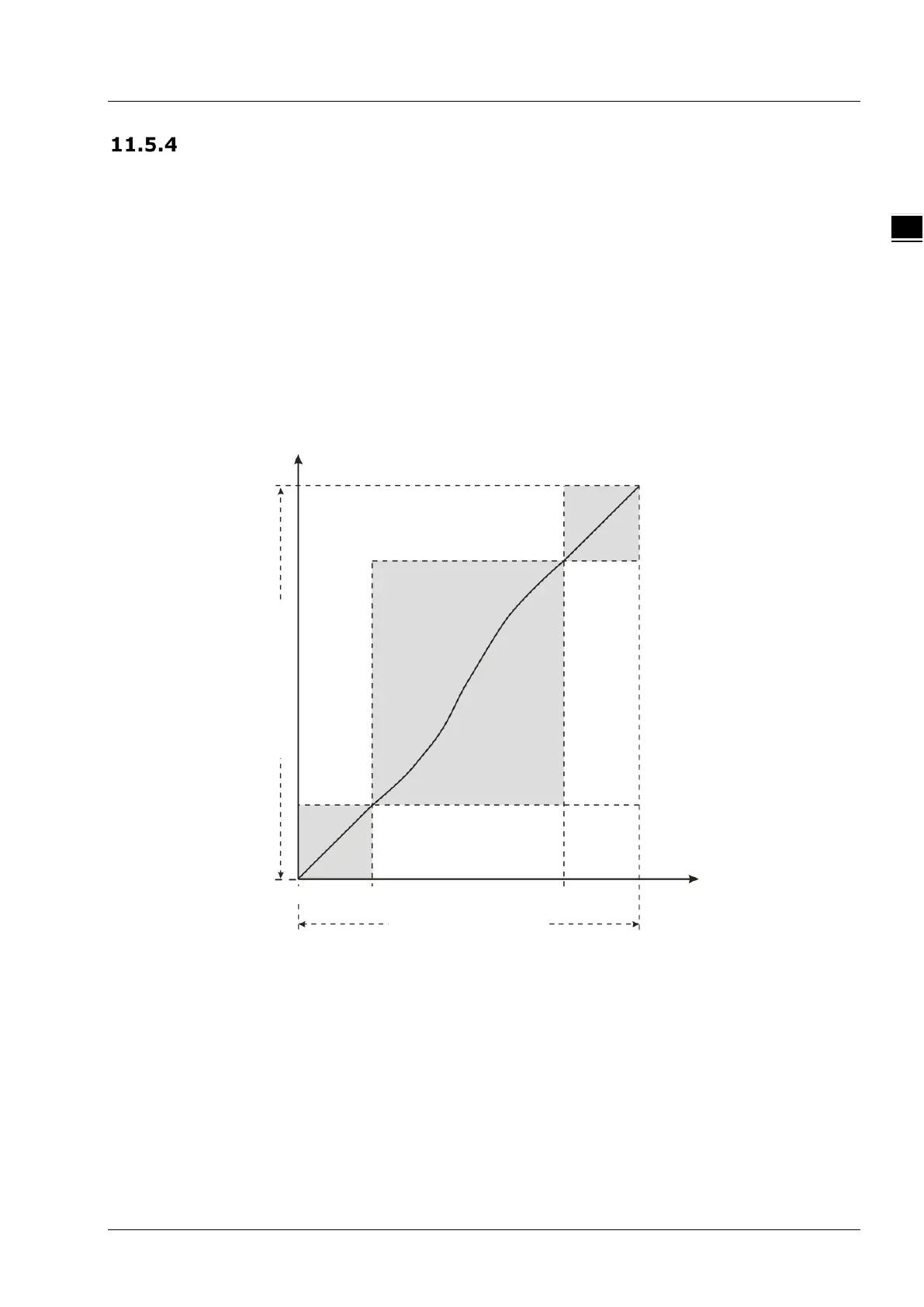

1. Short material cutting

When cutting length is less than the knife roller circumference, the rotary-cut curve for any cycle is

shown below.

For the cutting of short material, rotary cut axis must accelerate first in the adjustment area, and then

decelerate to the synchronous speed.

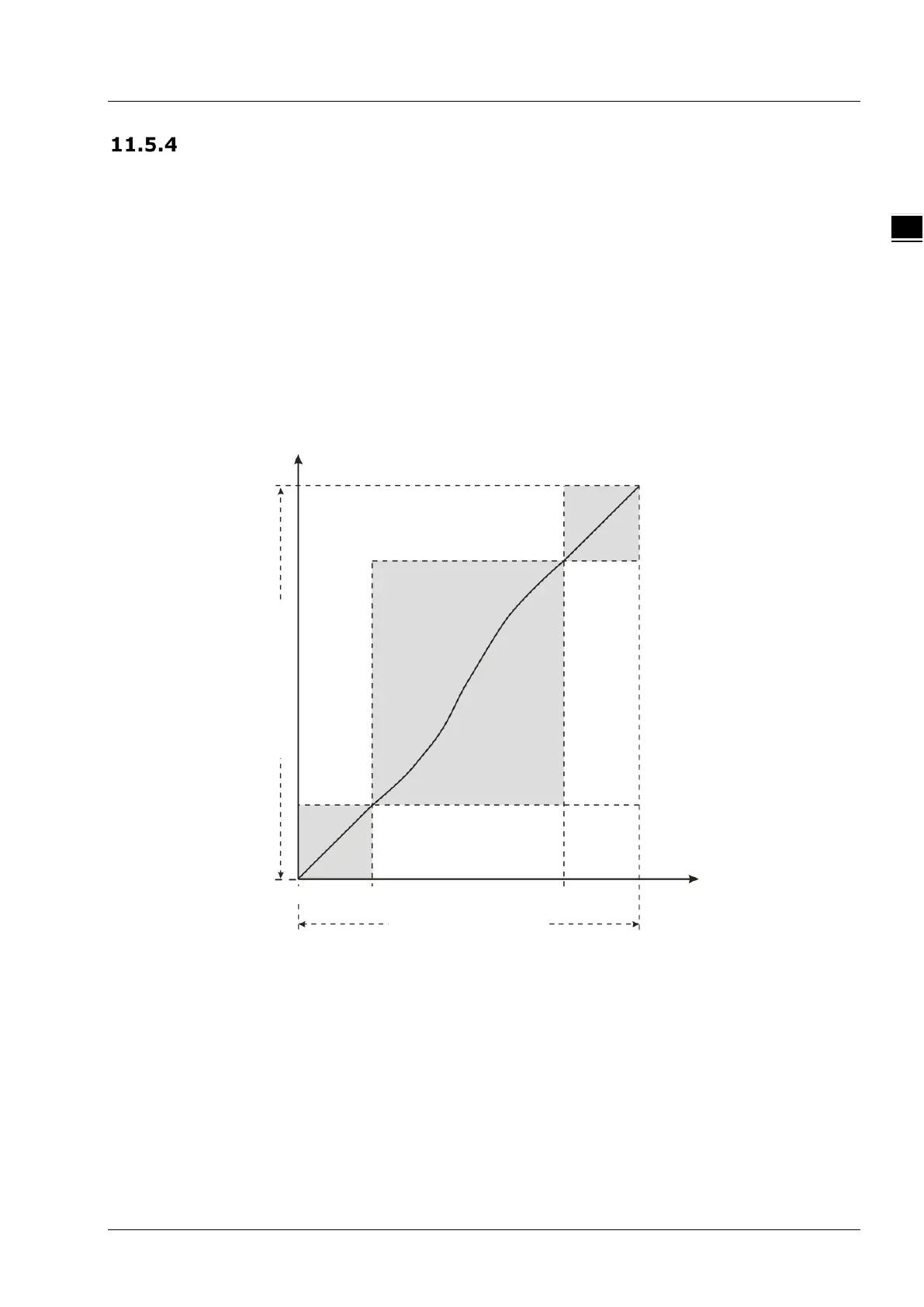

2. Equal-length cutting

When the cutting length is equal to the knife roller circumference, the rotary-cut curve for any cycle is

shown below.

area

the knife roller

than the knife roller

Loading...

Loading...