DVP-15MC Series Motion Controller Operation Manual

12-8

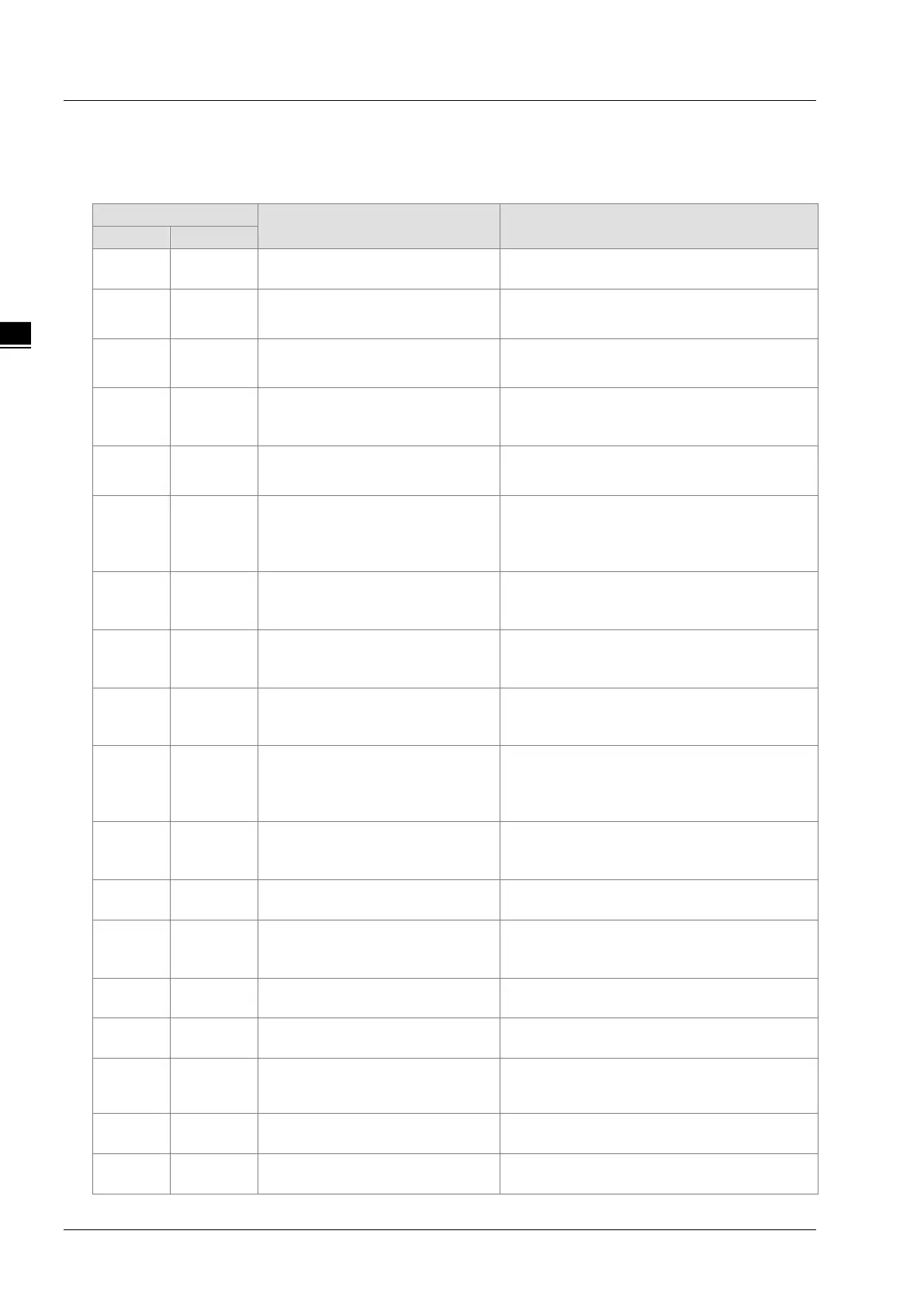

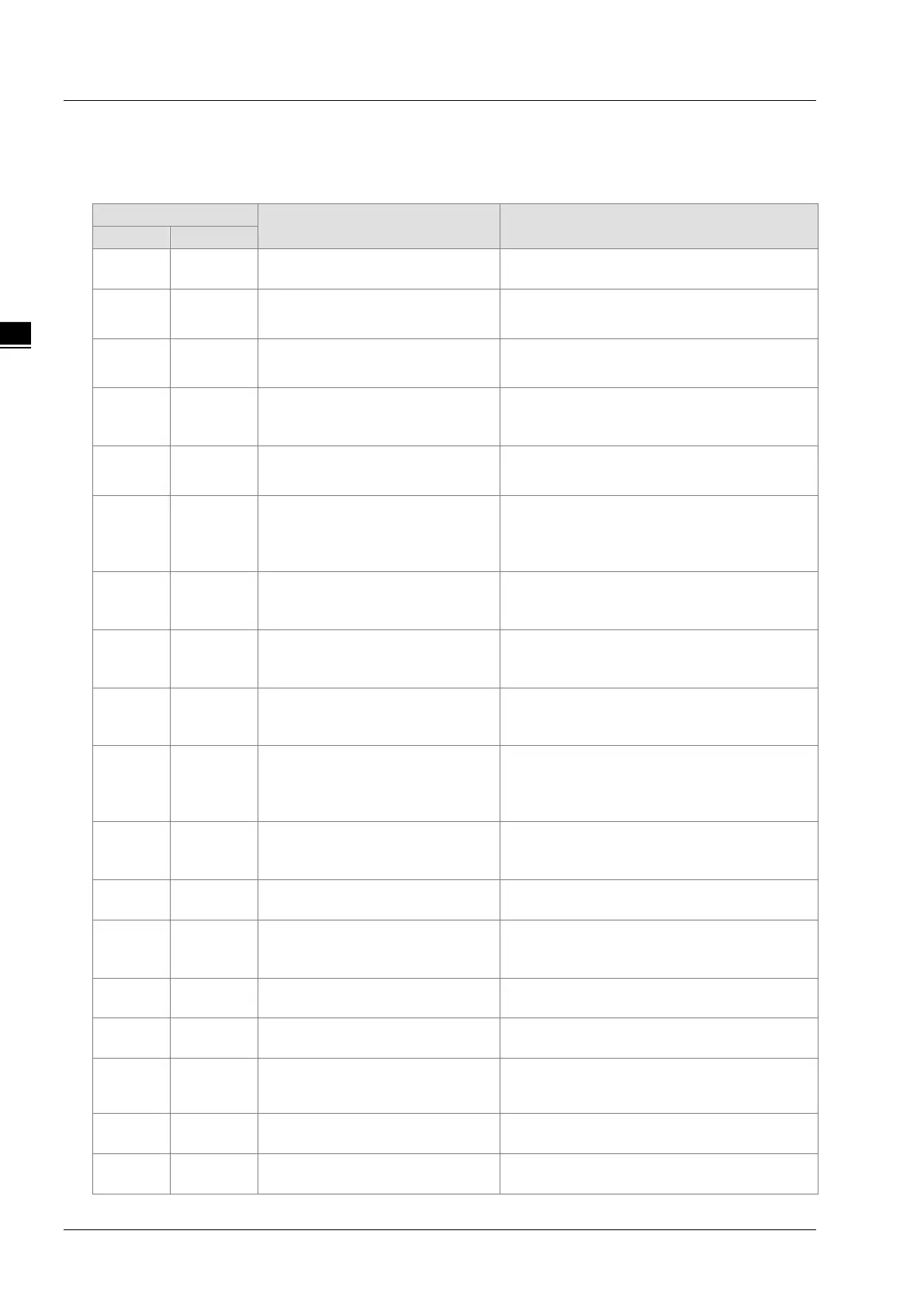

12.2 Table of Error IDs in Motion Instructions

When an error occurs in the motion instruction, the value of ErrorID can be seen as follows for analysis of

the cause and troubleshooting.

Meaning How to deal with

1001 4097

The axis No. exceeds the valid

range.

Make sure that the value of the input

variable, Axis is within the allowed range.

1002 4098

The acceleration exceeds the

valid range.

Make sure that the value of the input

variable, Acceleration is a positive number.

1003 4099

The deceleration exceeds the

valid range.

Make sure that the value of the input

variable, Deceleration is a positive number.

1004 4100

acceleration exceeds the valid

range.

Make sure that the value of the input

variable, Jerk is a positive number.

1005 4101

The velocity exceeds the valid

range.

Make sure that the value of the input

variable, Velocity is a nonzero value.

1006 4102

The position value exceeds the

valid range.

Make sure that the value of the input

variable, Position of MC_MoveAbsolute is

not greater than the value of Modulo among

1007 4103

The direction value exceeds the

valid range.

Modify the value of the input variable,

Direction into that which can be set in the

1008 4104

The buffermode value exceeds

the valid range.

Modify the value of the input variable,

BufferMode into that which can be set in the

1009 4105

The input value for reference

position type is wrong.

Modify the value of the input variable,

ReferenceType into that which can be set in

the instruction.

100A 4106

The timing for executing

MC_SetPosition is improper.

Change the timing of executing

MC_SetPosition. Do not execute

MC_SetPosition while MC_Home or

MC_Stop is being executed.

100B 4107

The number of e-cam table is

incorrect.

Modify the value of the input variable,

CamTable into that of CamId set in the

100C 4108

The axis No. of the master axis is

Make sure that the value of the input

variable, Axis is within the allowed range.

100D 4109

The input value of the

engagement mode is wrong.

Modify the value of the input variable,

StartMode into that which can be set in the

100E 4110

The value of the master scaling is

incorrect.

Make sure that the value of the input

variable, MasterScaling is a positive number.

100F 4111

The value of the slave scaling is

incorrect.

Make sure that the value of the input

variable, SlaveScaling is a nonzero value.

1010 4112

The chosen position

master axis is wrong.

Modify the value of the input variable,

MasterValueSource into that which can be

1011 4113

Conflict in the axis No. of the

master and slave axes.

Modify the values of the input variables,

Master and Slave into different values.

1012 4114 Wrong e-gear numerator value

Modify the value of the input variable,

Numerator into a nonzero value.

Loading...

Loading...