Grounding and Connectors CK721-A Installation and Operation

C-2 24-10349-8 Rev. B

This document contains confidential and proprietary information of Johnson Controls, Inc.

© 2012 Johnson Controls, Inc.

Check that grounding points are clean and free from paint or corrosion.

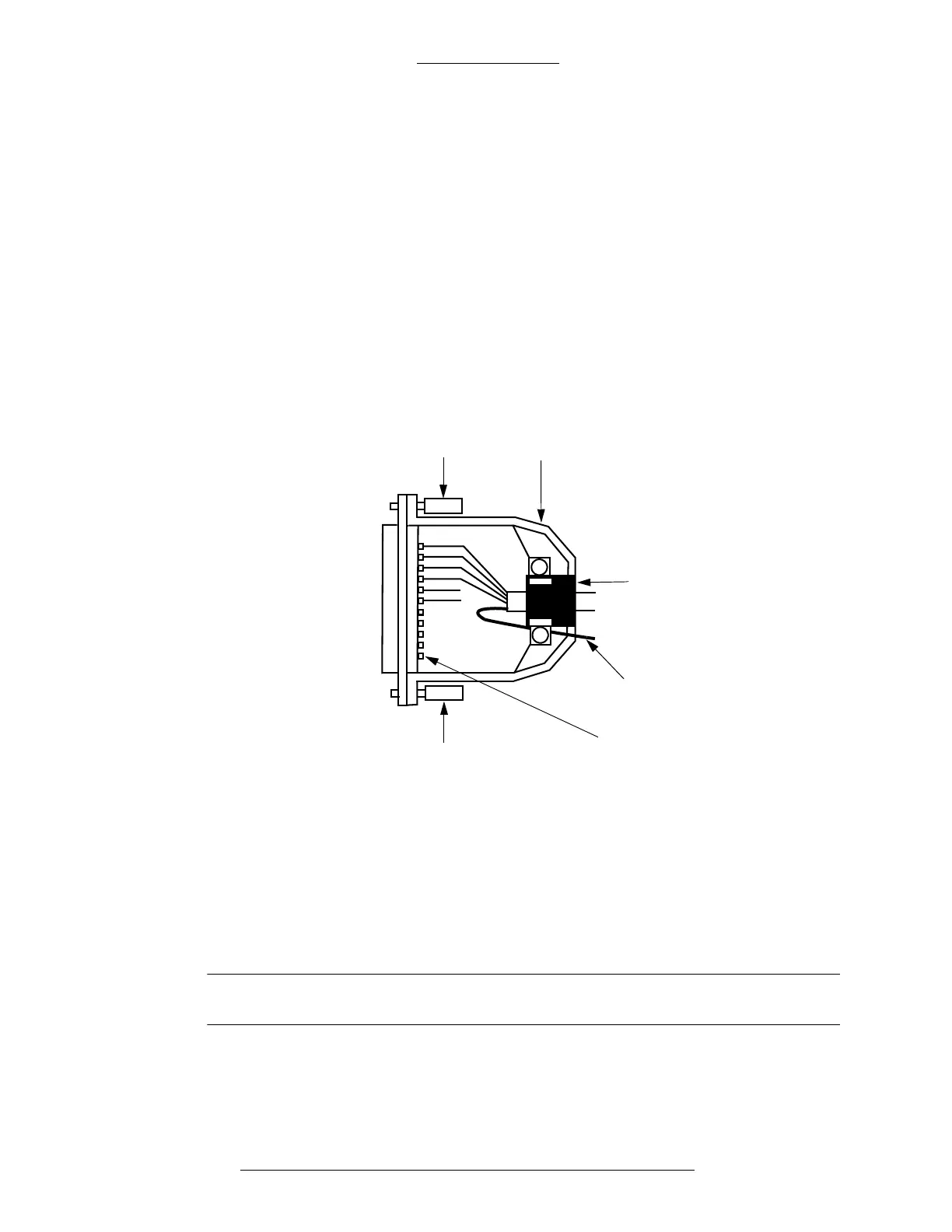

Figure C-1: Example of D-Type Connector Grounding

The two curved parts of the shroud shown in Figure C-1 make contact with the flat

plate of the shroud. Tighten the two remaining scr

ews to ensure a firm fit.

Do not remove the drain wire from the shield.

Do not connect the shield to connector pin 1 in any way.

“D-Type” Connectors

All D-type connectors must use Electromagnetic Interference (EMI) shielded

shroud. Ensure that a good contact is made when connecting D-type connector

shrouds to cable shields.

Figure C-1 shows a critical contact throughout the 360 deg

rees of the cable’s shield

at the point of entry to the shell. To ensure a good fit, strip back the cable’s ou

tside

layer to reveal the metal shield and extend the shield to the very edge of the metal

shroud’s connector. If the shield does not fit snugly, apply metallic tape to ensure a

firm contact.

Metal or metallized

connector shroud

Rubber bushing

Do not connect

cable shield to pin 1

Ensure that screws are

tight so the metal pieces

of the shroud are joined

securely here

Retaining

screws (2)

Cable shield pigtail

brought through

connector shroud

IMPORTANT

Loading...

Loading...