262334 135 Revision A

4.6 Lubrication

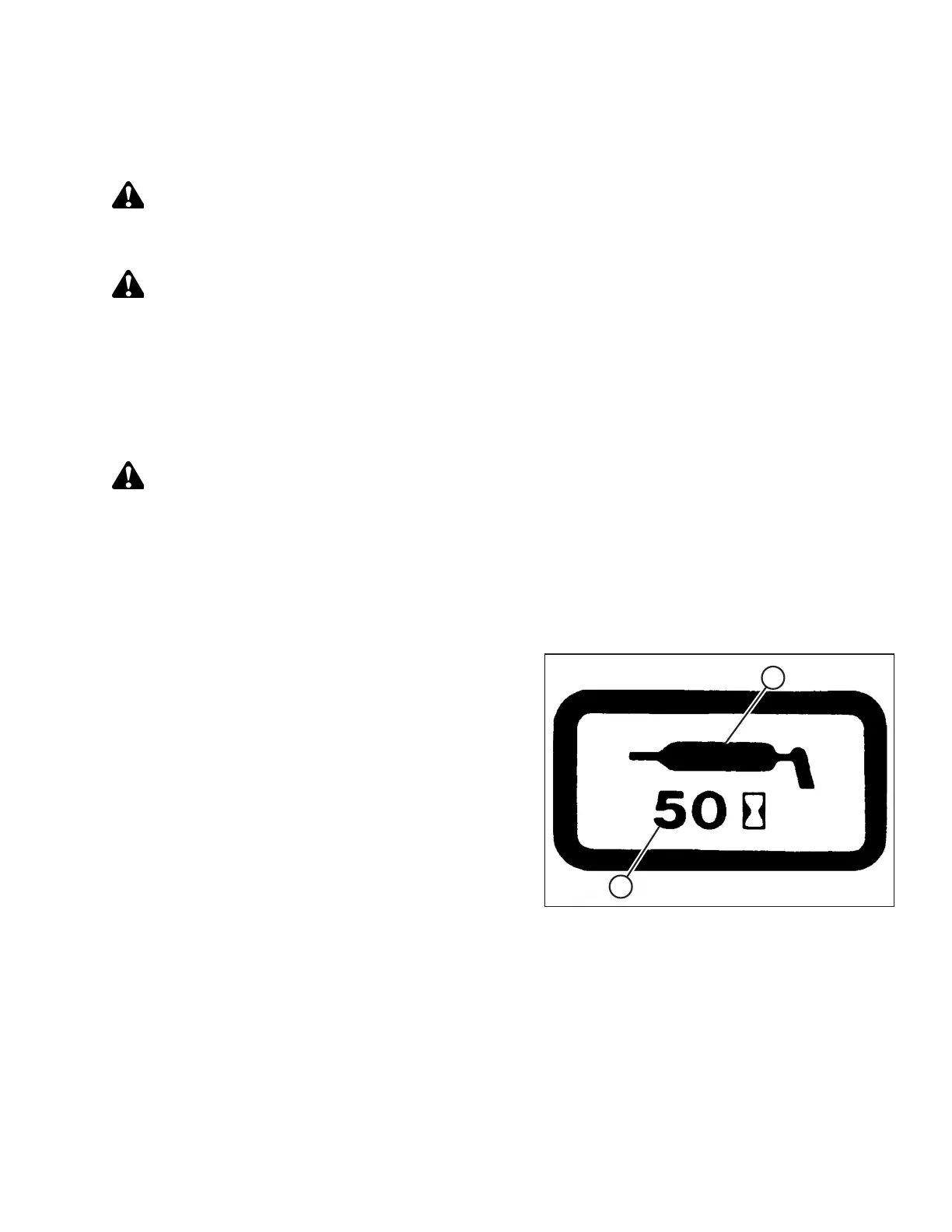

Greasing points are marked on the machine by decals showing a grease gun and the grease interval in hours of operation.

CAUTION

To avoid personal injury, before servicing header or opening drive covers, follow procedures in 4.1 Preparing for

Servicing, page 125.

CAUTION

Refer to inside back cover for recommended greases.

Log hours of operation and use the Maintenance Checklist provided to keep a record of scheduled maintenance. Refer to

4.5.1 Maintenance Schedule/Record, page 132.

4.6.1 Greasing Procedure

Some header components need to be lubricated in order to perform their function correctly and prevent machine damage.

DANGER

To avoid bodily injury or death from the unexpected start-up or fall of a raised machine, always shut down the engine

and remove the key before leaving the operator’s seat, and always engage the safety props or close the lock-out valves

before going under the machine for any reason.

The greasing points are marked on the machine by decals showing a grease gun (A) and grease interval (B) in hours of

operation.

Use the recommended lubricants specified in this manual on the inside back cover.

Figure 4.8: Grease Interval Decal

1. Wipe the grease fitting with a clean cloth before greasing it

to avoid injecting dirt and grit.

2. Inject the grease through the fitting with a grease gun until

the grease overflows the fitting, except where noted.

3. Leave excess grease on the fitting to keep out dirt.

4. Replace any loose or broken fittings immediately.

5. If the fitting will not take grease, remove and clean the

fitting and the lubricant passageway thoroughly. Replace

the fitting if necessary.

4.6.2 Lubrication Points

Lubrication requirements depend on the model of the header that is being serviced.

Refer to the lubrication points for your specific model:

• Lubrication Points: Auger Header, page 136

• Lubrication Points: Hay Conditioner, page 138

• Lubrication Points: Drivelines, page 139

MAINTENANCE AND SERVICING

Loading...

Loading...