262334 158 Revision A

Adjusting Knife Hold-Down: Center Guard – Double-Knife Header

To adjust the hold-down at the double-knife center pointed guard, follow the recommended adjustment procedure

provided here.

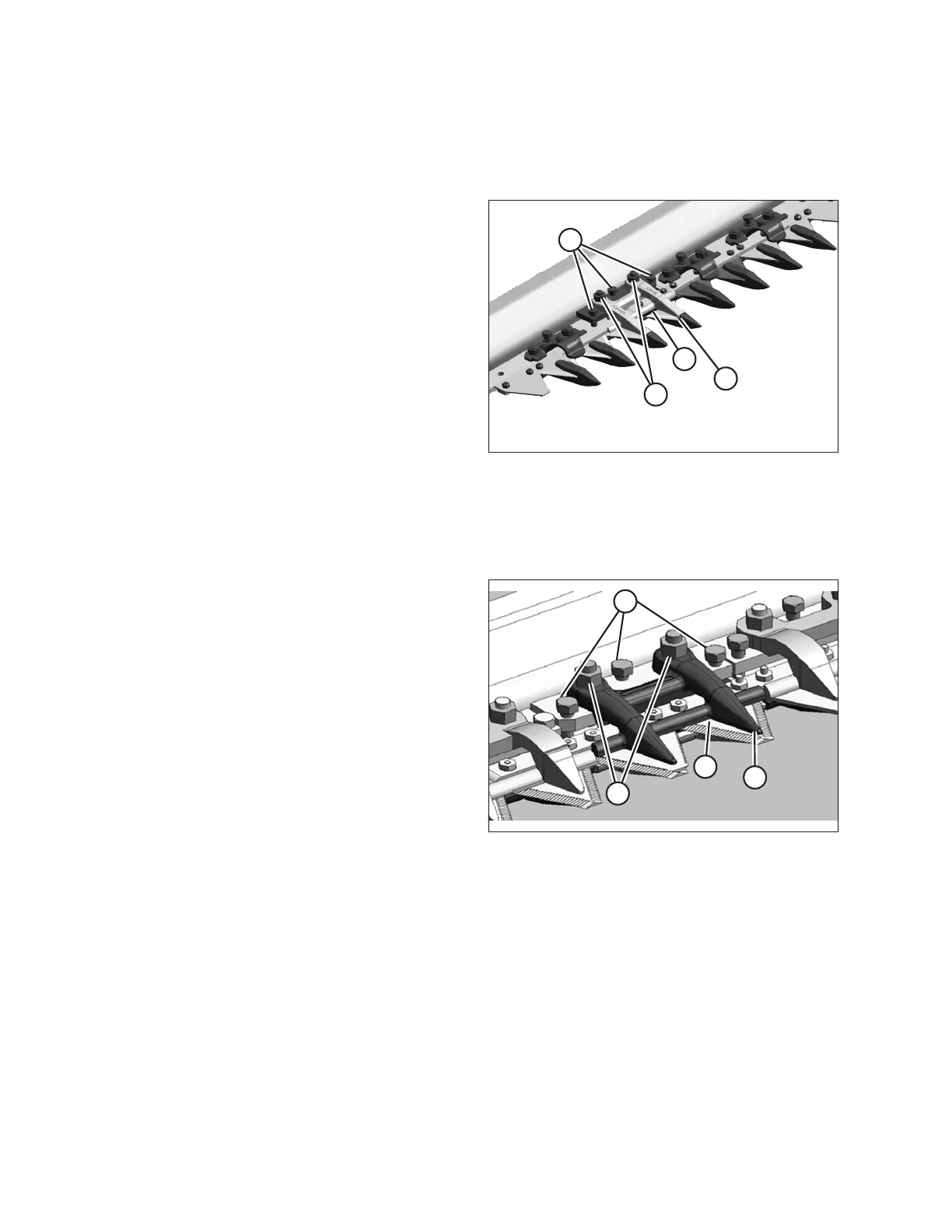

Figure 4.46: Knife Hold-Down – Double Knife

1. Torque nuts (A) to 46 Nm (35 lbf·ft).

2. Turn adjuster bolts (B). Using a feeler gauge, the clearance

from the hold-down to knife section (C) should be:

• 0.1–0.4 mm (0.004 –0.016 in.) at the guide tip (C)

• 0.1–1.0 mm (0.004 –0.040 in.) at rear of guide (D)

3. Torque nuts (A) to 72 Nm (53 lbf·ft).

4. After adjusting all the hold-downs, run the header at a low

engine speed, and listen for noise due to insufficient

clearance. An insufficient clearance will cause the knife and

the guards to overheat.

Adjusting Knife Hold-Down: Stub Guard – Double-Knife Header

To adjust the hold-down at the double-knife stub guard, follow the recommended adjustment procedure provided here.

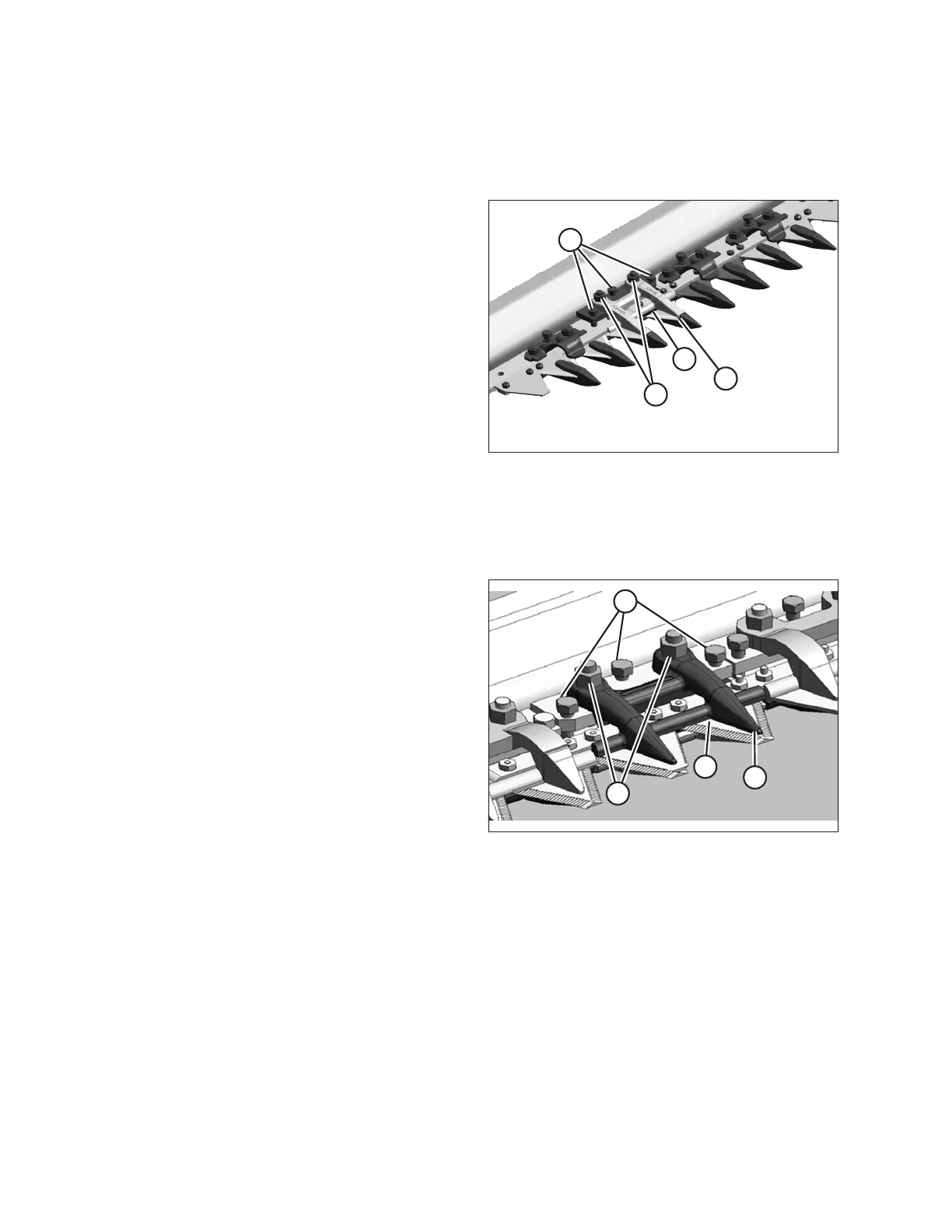

Figure 4.47: Stub Guard – Double Knife

1. Torque nuts (A) to 46 Nm (35 lbf·ft).

2. Turn adjuster bolts (B). Using a feeler gauge, the clearance

from the hold-down to the knife section should be:

• 0.1–0.4 mm (0.004 –0.016 in.) at the guide tip (C)

• 0.1–1.0 mm (0.004 –0.040 in.) at rear of guide (D)

3. Torque nuts (A) to 72 Nm (53 lbf·ft).

4. After adjusting all the hold-downs, run the header at a low

engine speed, and listen for noise due to insufficient

clearance. An insufficient clearance will cause the knife and

the guards to overheat.

MAINTENANCE AND SERVICING

Loading...

Loading...