262334 192 Revision A

4.13 Stripper Bar

Stripper bars help prevent the crop from wrapping around the auger and improve crop flow into the conditioner.

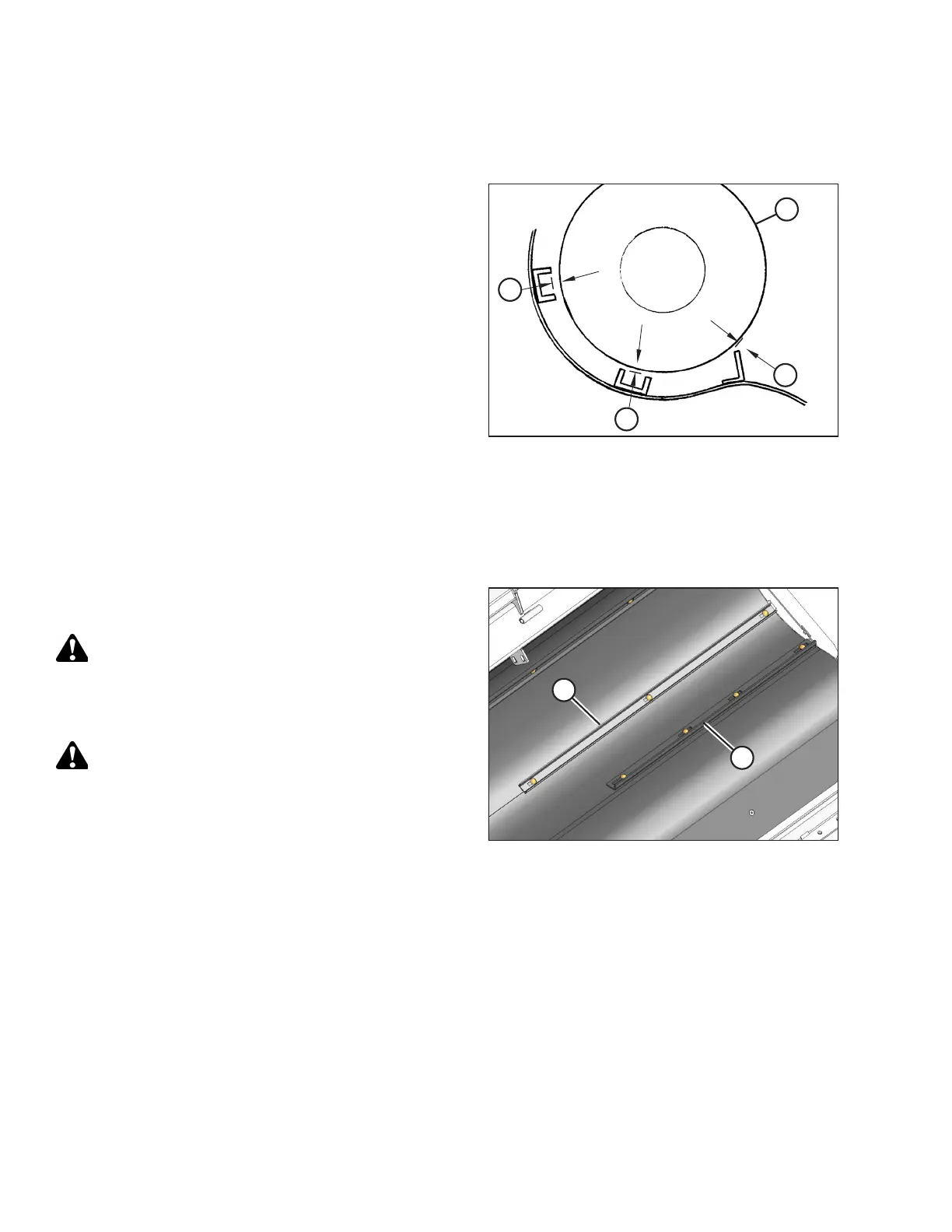

Figure 4.123: Auger to Stripper Bar Clearance

To maintain 1–4 mm (1/32–5/32 in.) clearance (B) between

auger (A) flighting and stripper bars, bars may need replacing

due to wear or damage. Shims may also need to be installed to

compensate for local irregularities in the structure.

If auger position needs to be adjusted after adjusting stripper

bars, refer to 3.8.4 Setting Auger Position, page 79.

4.13.1 Removing Stripper Bar

Heavy crops may cause plugging across the auger due to restricted flow at the stripper bars. To address this problem,

remove the lower stripper bar, and if necessary, the center stripper bar at each end of the header.

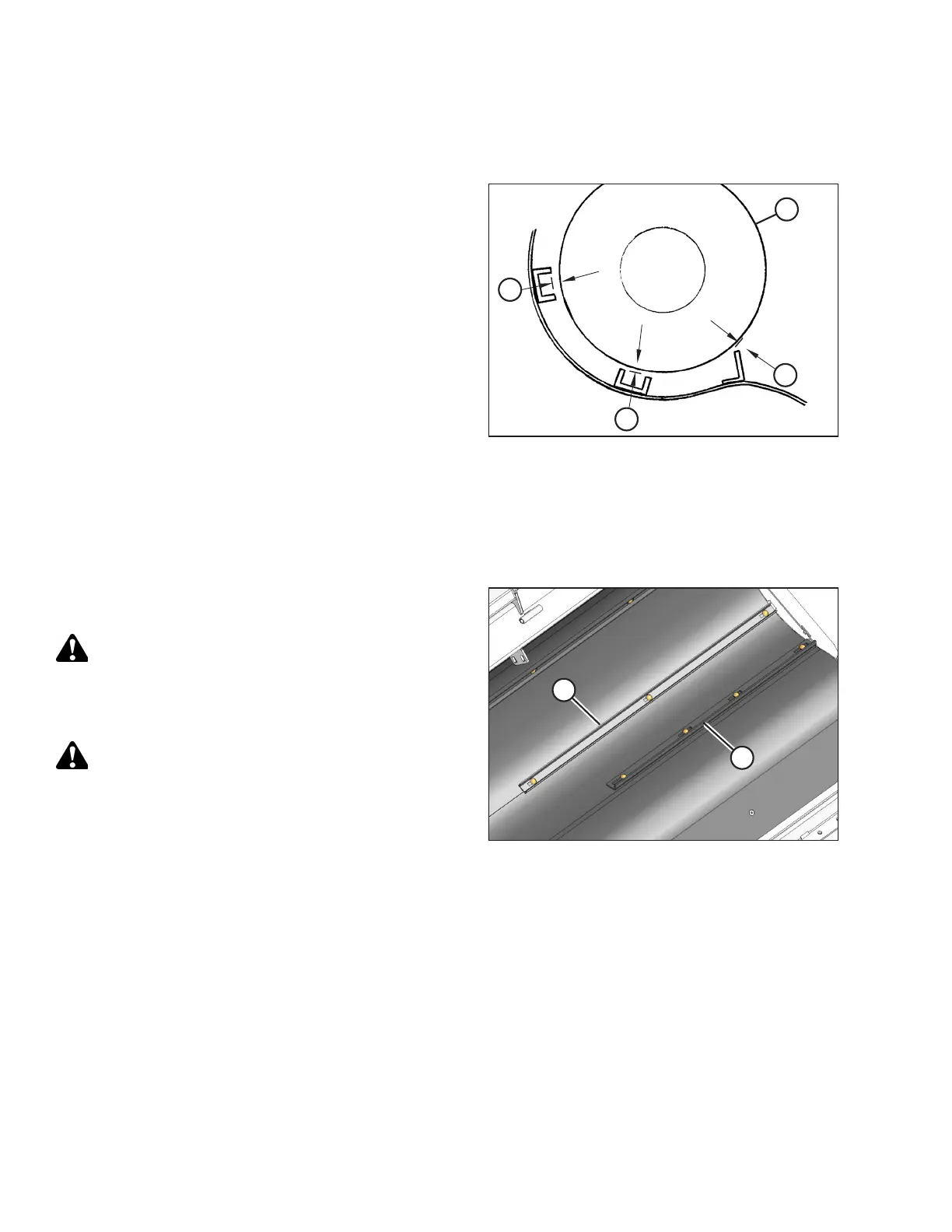

Figure 4.124: Stripper Bars

The location of lower stripper bar (A) and center stripper bar (B)

are shown on the illustration at right.

DANGER

To avoid bodily injury or death from the unexpected start-up or

fall of a raised machine, shut down the engine, remove the key,

and engage the safety props before going under the machine.

DANGER

To avoid bodily injury or death from fall of raised machine,

always lock-out lift cylinders before going under header for any

reason.

To remove a stripper bar, follow these steps:

1. Shut down the engine, and remove the key from the ignition.

2. Remove the bolts attaching the stripper bar to the pan.

3. Remove the nuts and bolts that secure the stripper bar to the pan.

4. Replace the bolts in the pan.

NOTE:

Special countersunk bolts are available from your Dealer.

MAINTENANCE AND SERVICING

Loading...

Loading...