262334 159 Revision A

4.8.9 Knife Drive Box

The knife drive box converts rotational motion from the windrower header driveshaft to reciprocating motion for the knife.

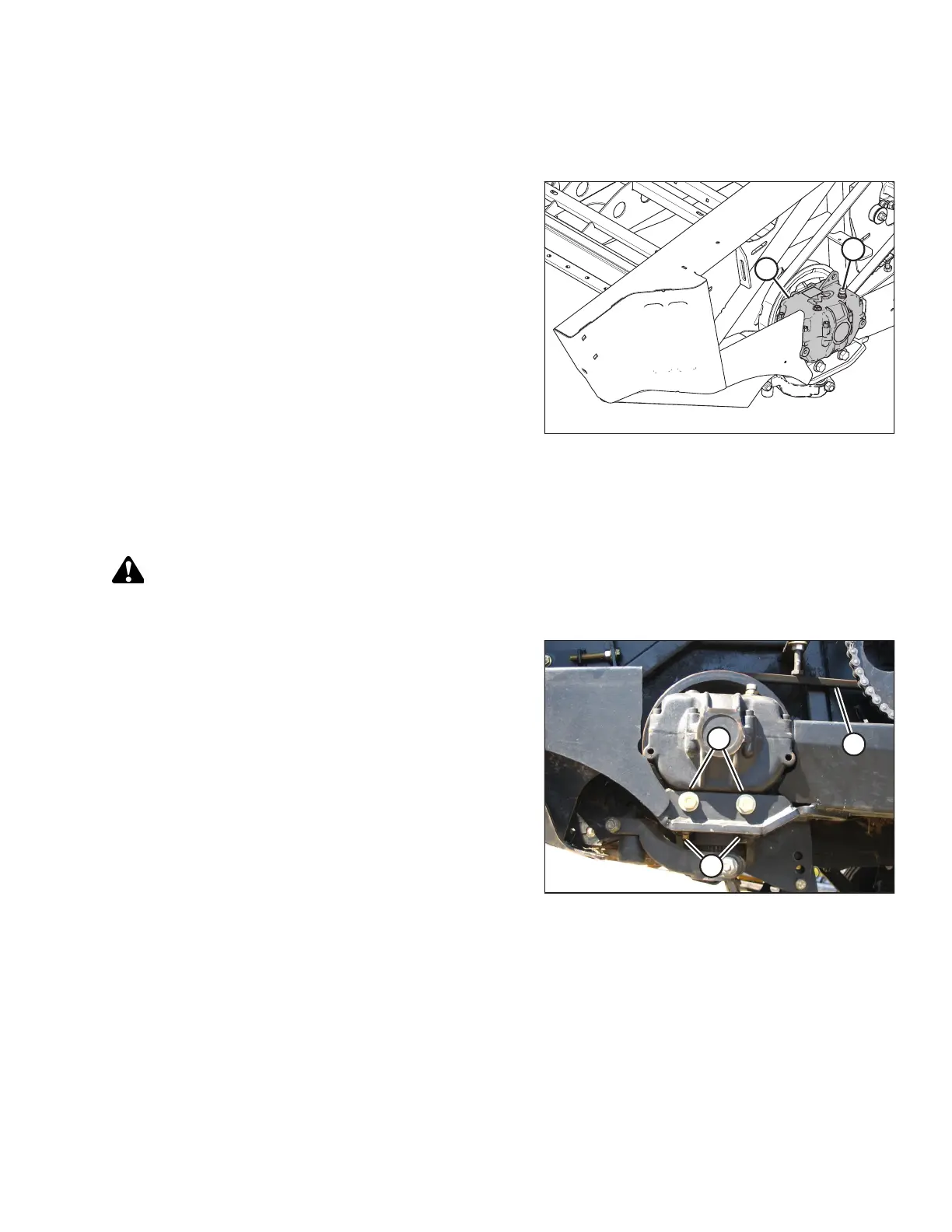

Figure 4.48: Knife Drive Box

Heavy-duty oil bath knife drive box (A) uses tapered roller

bearings on the input shaft and the yoke for increased

durability. The pulley and drive arm connections are straight

splines with clamping bolts.

Check the oil level in knife drive box (A) with the dipstick that is

incorporated into breather (B).

Checking Mounting Bolts

The mounting bolts must be checked occasionally to maintain the performance of the header.

DANGER

To avoid bodily injury or death from the unexpected startup of the machine, always stop the engine and remove the

key from the ignition before leaving the operator’s seat for any reason.

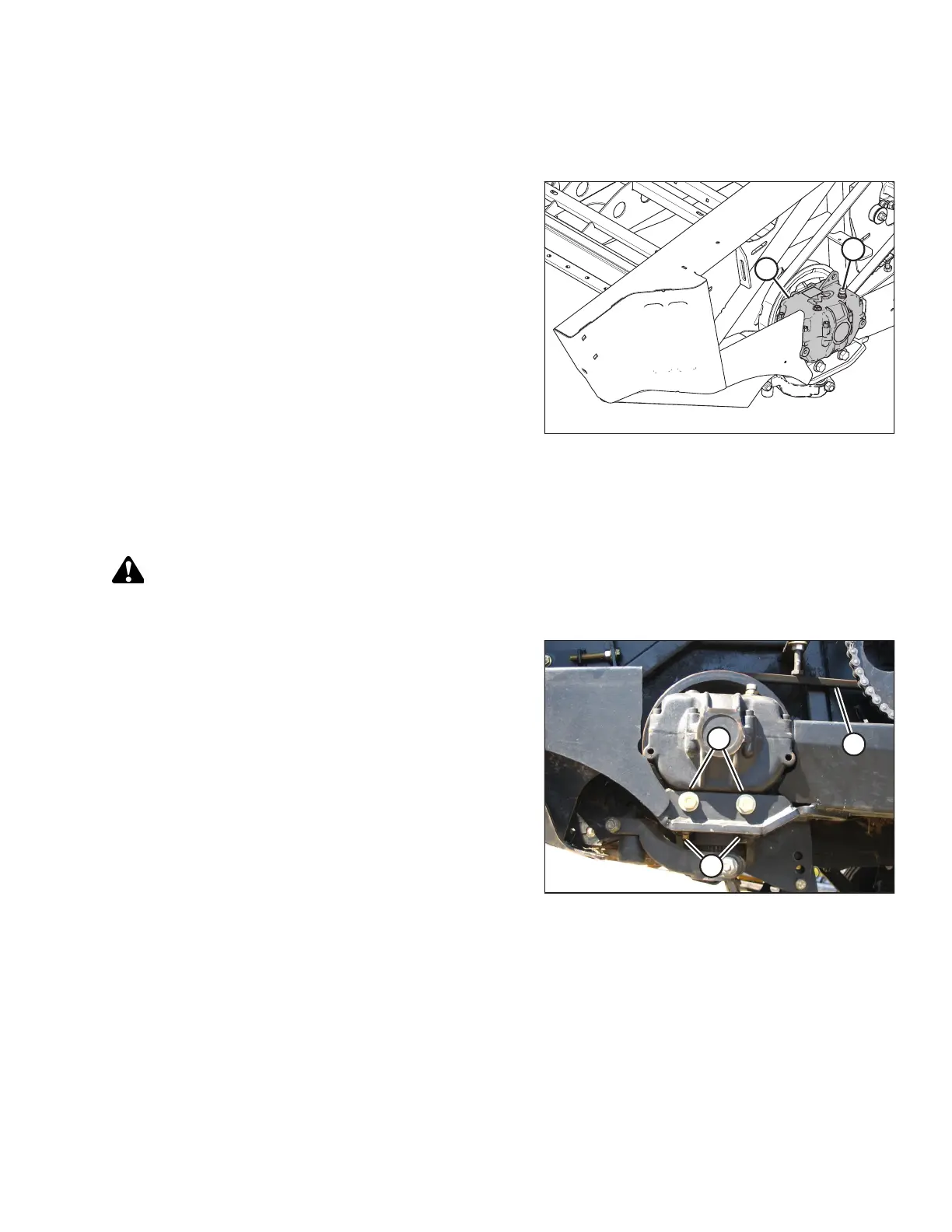

Figure 4.49: Knife Drive Box

Check the torque of four knife drive box mounting bolts (A)

after the first 10 hours of operation, and every 100 hours

thereafter. Torque the bolts to 270 Nm (200 lbf·ft). When

tightening the bolts, start with the side mounting bolts.

MAINTENANCE AND SERVICING

Loading...

Loading...