262334 146 Revision A

4.8.4 Removing Knifehead Bearing

The knifehead bearing allows the knifehead pin to rotate within the knifehead as the drive arm strokes the knife back and

forth. If the bearing is worn or damaged, it will need to be replaced.

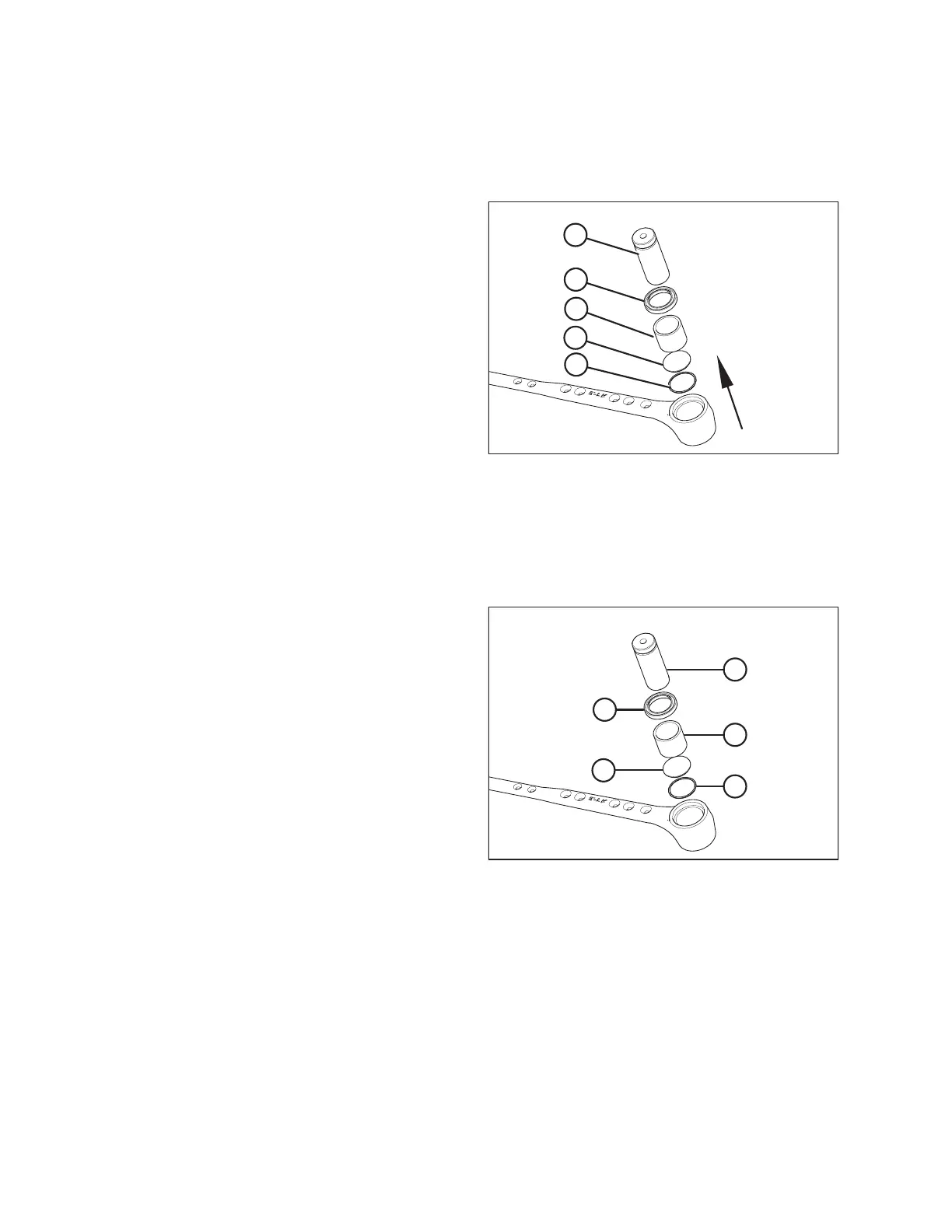

Figure 4.22: Bearing Removal

1. Remove the knife. For instructions, refer to 4.8.2 Removing

Knife, page 144 .

2. Using a flat-ended tool with approximately the same

diameter as plug (D), tap out seal (B), bearing (C), plug (D),

and O-ring (E) from the underside of the head.

NOTE:

The seal can be replaced without removing the bearing.

When changing the seal, check pin (A) and the needle

bearing for wear. Replace the seal if necessary.

4.8.5 Installing Knifehead Bearing

The knifehead bearing, seals, and greasing interval protect the knifehead from the forces of the knife drive output arm. The

seals and bearing require inspection and, when worn, replacement to prevent damage.

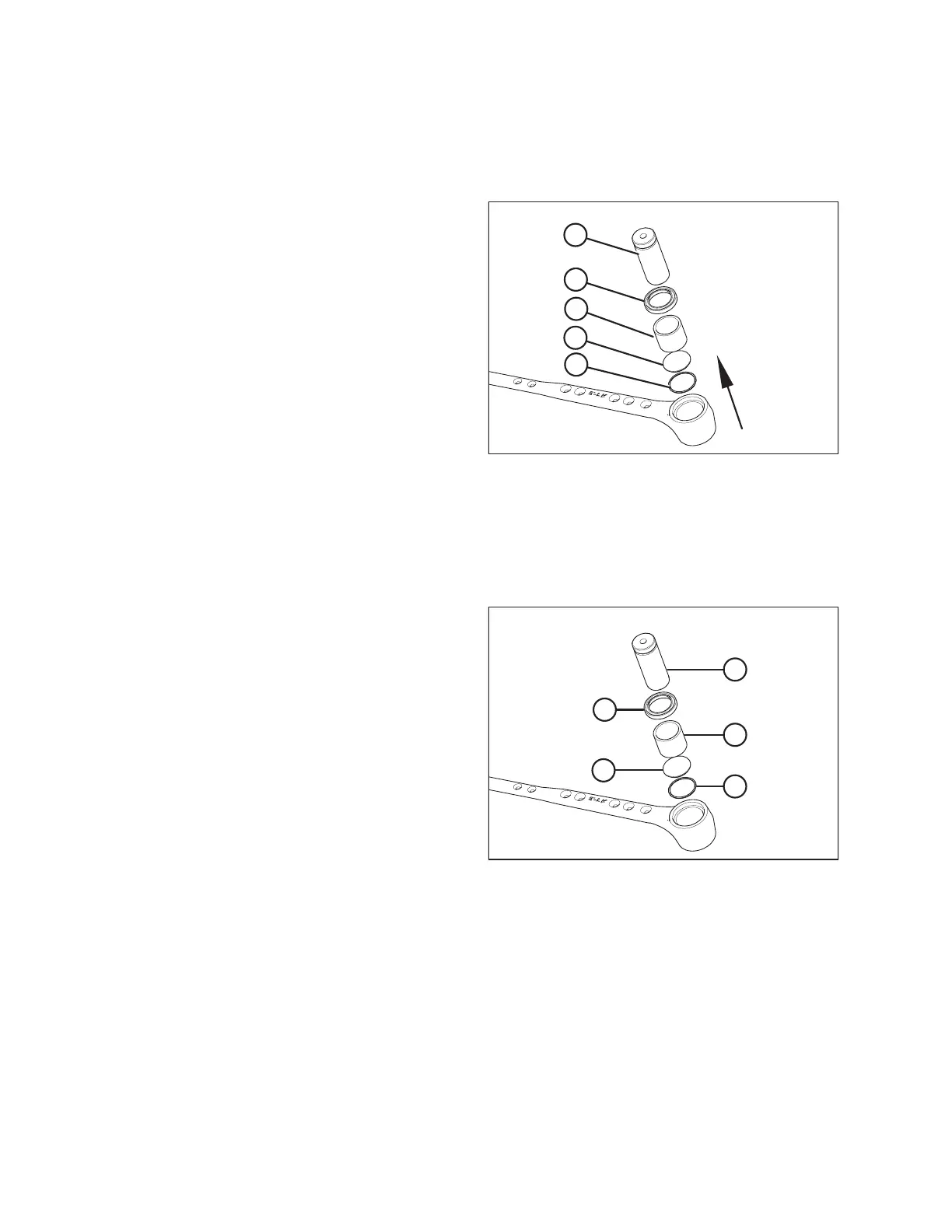

Figure 4.23: Knifehead Bearing Assembly

1. Place O-ring (E) and plug (D) into the knifehead.

IMPORTANT:

Install the bearing with the stamped end (the end with the

identification markings) facing up.

NOTE:

It may be necessary to temporarily remove the grease

fitting from the knifehead during installation of the

knifehead pin. This will allow any trapped air to escape and

the knifehead pin will seat correctly.

2. Use a flat-ended tool with the same approximate diameter

as bearing (C), and push the bearing into the knifehead

until the top of the bearing is flush with the step in the

knifehead.

3. Install seal (B) into the knifehead with the lip facing

outwards.

IMPORTANT:

To prevent premature knifehead or knife drive box failure,

ensure there is a tight fit between knifehead pin (A) and

the needle bearing, and between the knifehead pin and the

output arm.

4. Install the knife. For instructions, refer to 4.8.3 Installing Knife, page 145.

MAINTENANCE AND SERVICING

Loading...

Loading...