262334 239 Revision A

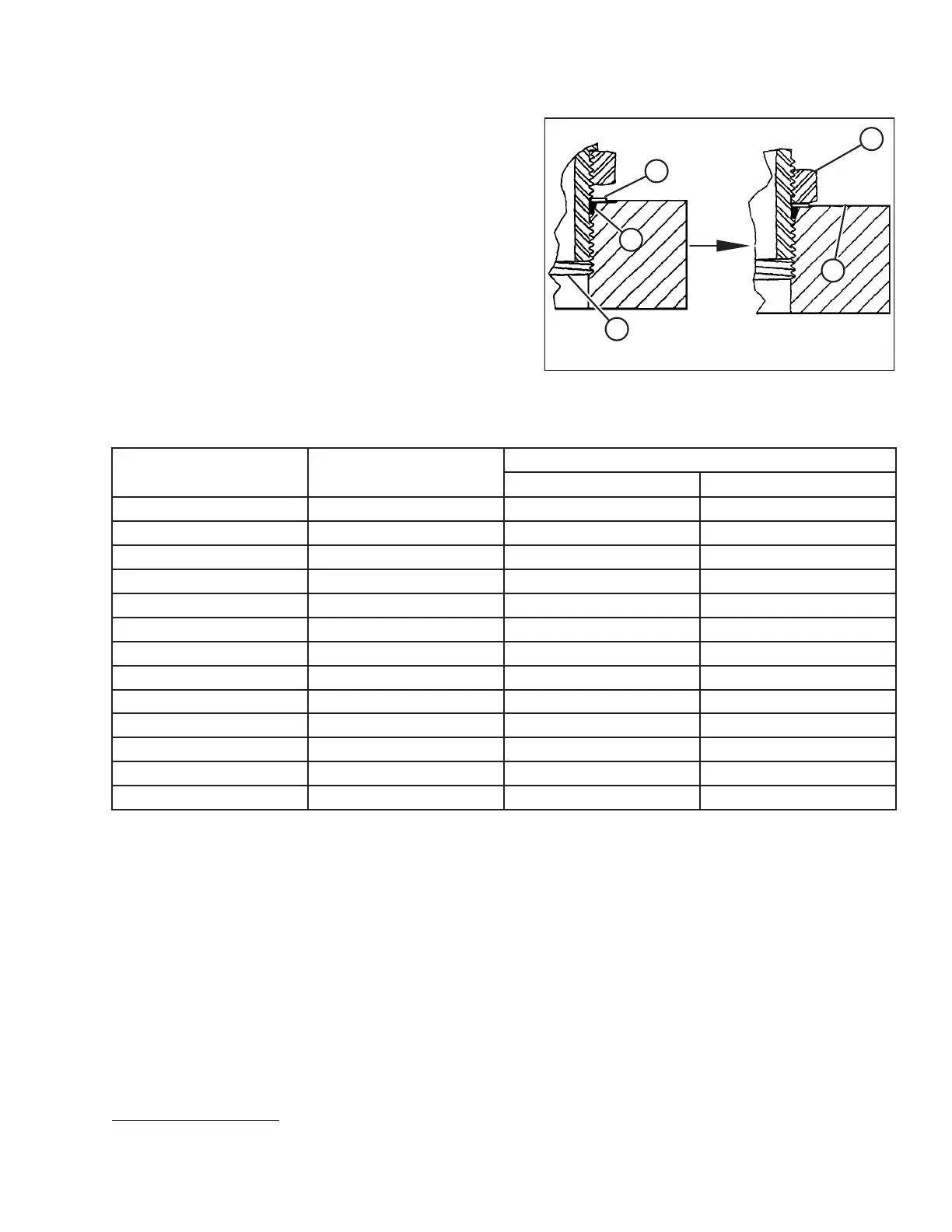

Figure 7.12: Hydraulic Fitting

5. Install fitting (B) into the port until backup washer (D) and

O-ring (A) contact part face (E).

6. Position the angle fittings by unscrewing no more than

one turn.

7. Turn lock nut (C) down to washer (D) and tighten it to the

torque value indicated in the table. Use two wrenches, one

on fitting (B) and the other on lock nut (C).

8. Verify the final condition of the fitting.

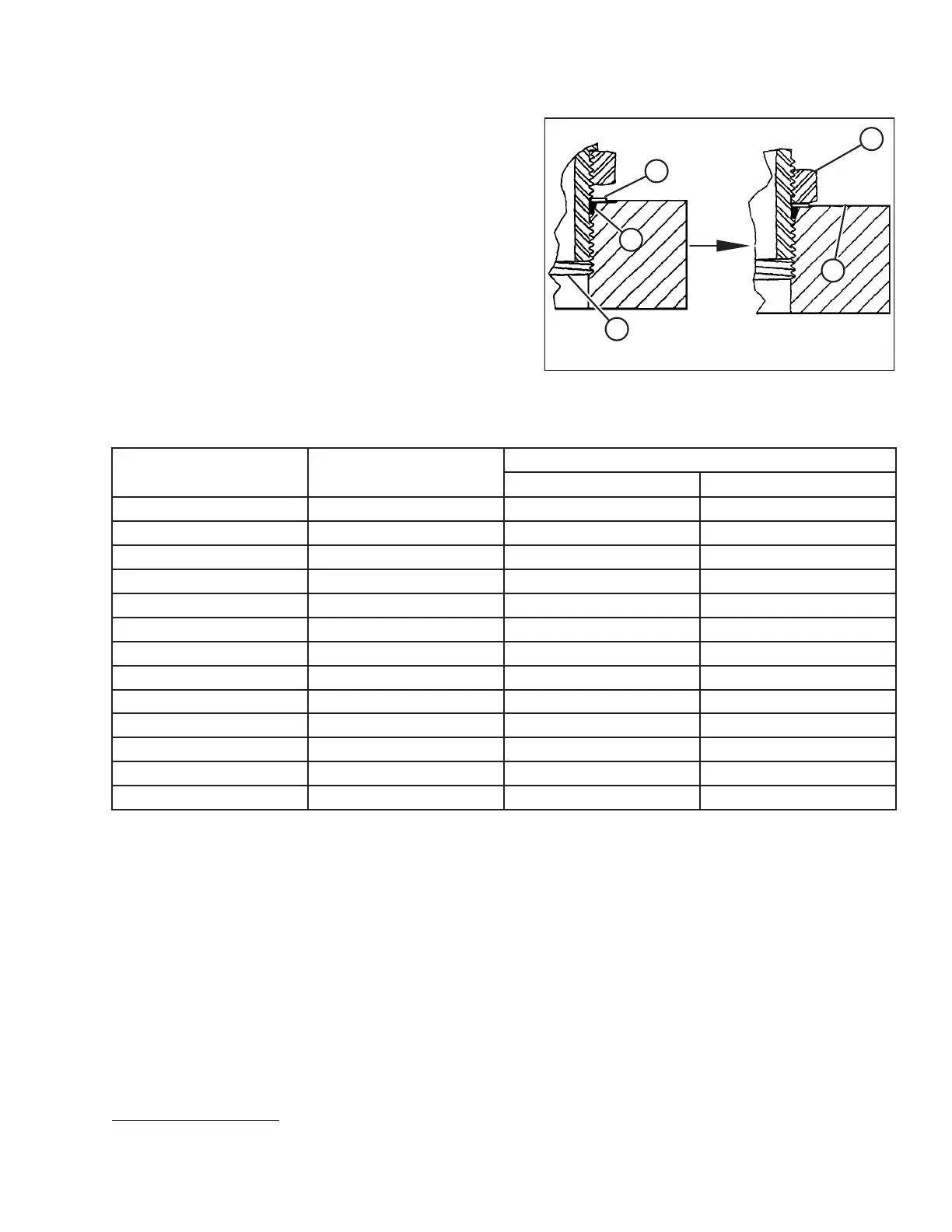

Table 7.11 O-Ring Boss (ORB) Hydraulic Fittings – Adjustable and Non-Adjustable

SAE Dash Size

Thread Size (in.)

Torque Value

7

Nm

lbf·ft (*lbf·in)

-2

5/16–24

10–11 *89–97

-3

3/8–24

18–20 *159–177

-4

7/16–20

29–32

21–24

-5

1/2–20

32–35 24–26

-6

9/16–18

40–44 30–32

-8

3/4–16

70–77 52–57

-10

7/8–14

115–127 85–94

-12

1 1/16–12

183–201 135–148

-14

1 3/16–12

237–261 175–193

-16

1 5/16–12

271–298 200–220

-20

1 5/8–12

339–373 250–

275

-24

1 7/8–12

414–455 305–336

-32

2 1/2–12

509–560 375–413

REFERENCE

7. Torque values shown are based on lubricated connections as in reassembly.

Loading...

Loading...