Detailed description

2.2 Protection zones

Basic logic functions: Axis monitoring, protection zones (A3)

48 Function Manual, 11/2006, 6FC5397-0BP10-2BA0

)

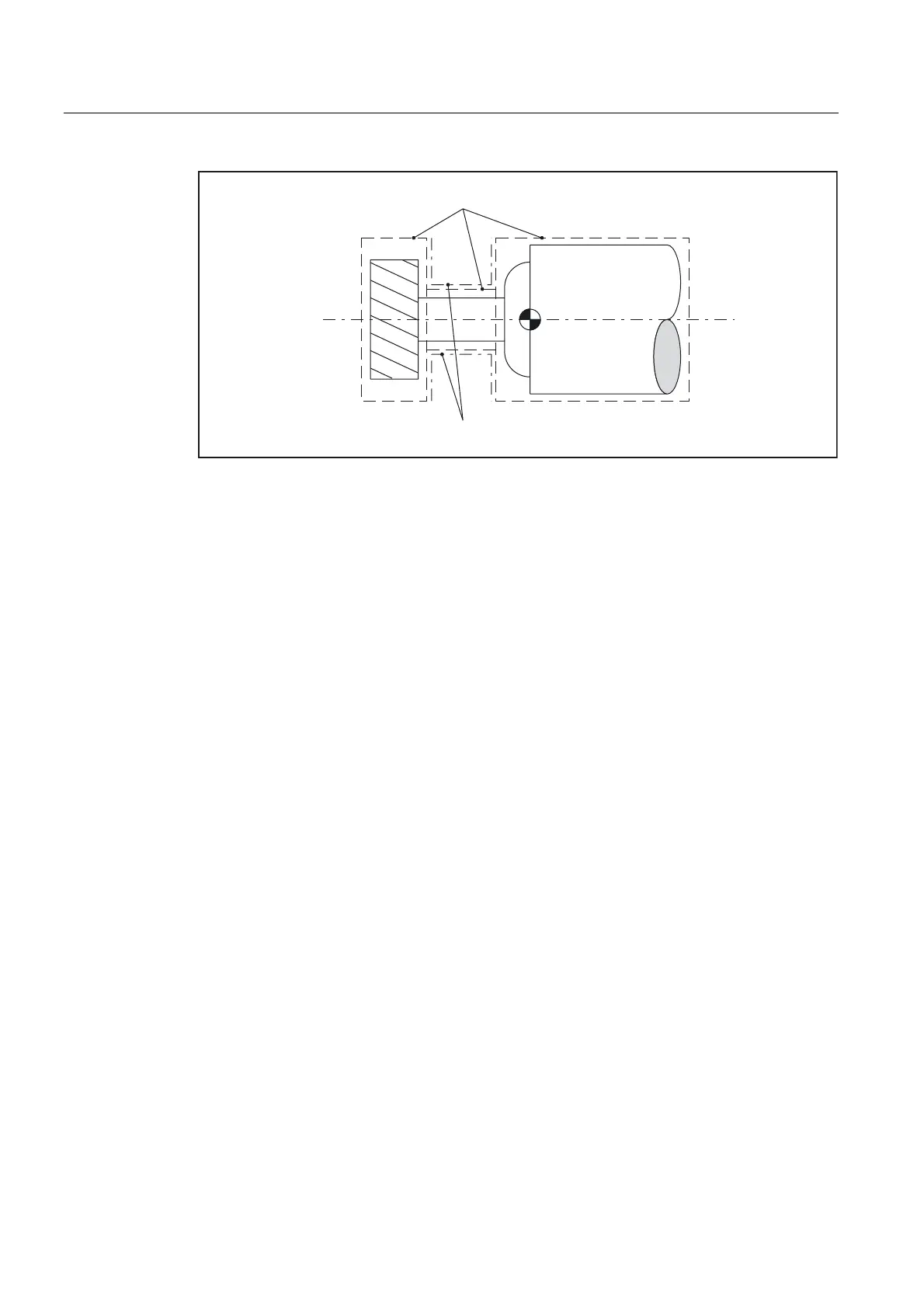

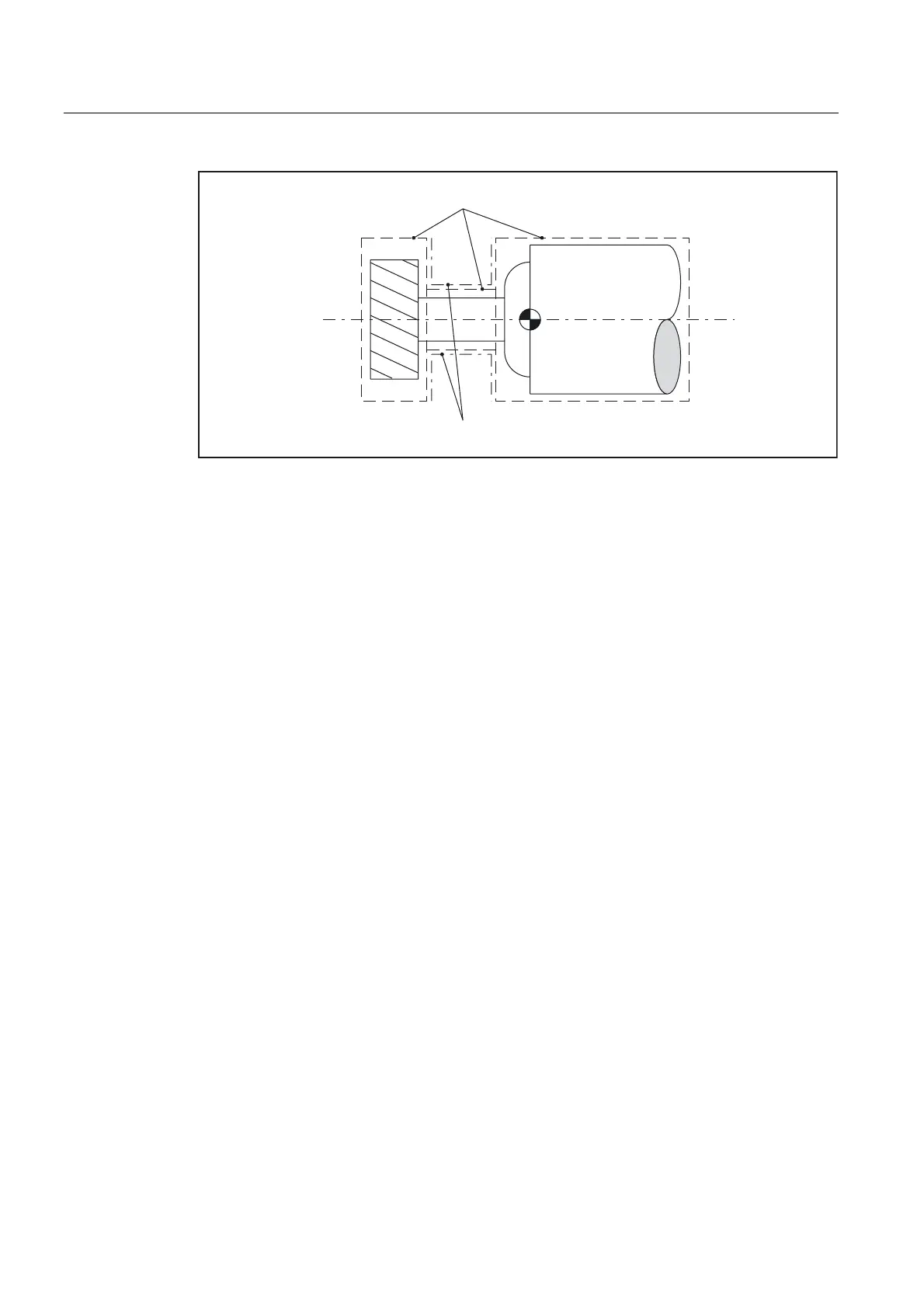

&RQYH[SURWHFWLRQ]RQHV

&RQFDYHSURWHFWLRQ]RQHVQRWSHUPLVVLEOH

Figure 2-12 Examples: convex and concave tool-related protection zones

Contour elements

The following contour elements are permissible:

• G0, G1 for straight contour elements

• G2 for circle segments in the clockwise direction

Permissible only for workpiece-related protection zones.

Not permissible for tool-related protection zones because they must be convex.

• G3 for circular segments in the counter clockwise direction

A protection zone cannot be described by a complete circle. A complete circle must be

divided into two half circles.

The sequence G2, G3 or G3, G2 is not permitted. A short G1 block must be inserted

between the two circular blocks.

Constraints

During the definition of a protection zone, the following functions must not be active or used:

• Tool radius compensation (cutter radius compensation, tool nose radius compensation)

• Transformation

• Reference point approach (G74)

• Fixed point approach (G75)

• Dwell time (G4)

• Block search stop (STOPRE)

• End of program (M17, M30)

• M functions: M0, M1, M2

Programmable frames (TRANS, ROT, SCALE, MIRROR) and configurable frames (G54 to G57)

are ineffective.

Inch/metric switchovers with G70/G71 or G700/G710 are effective.

Loading...

Loading...