Detailed description

2.9 Zero mark selection with BERO

Basic logic functions: Reference Point Approach (R1)

54 Function Manual, 11/2006, 6FC5397-0BP10-2BA0

2.9 Zero mark selection with BERO

Function

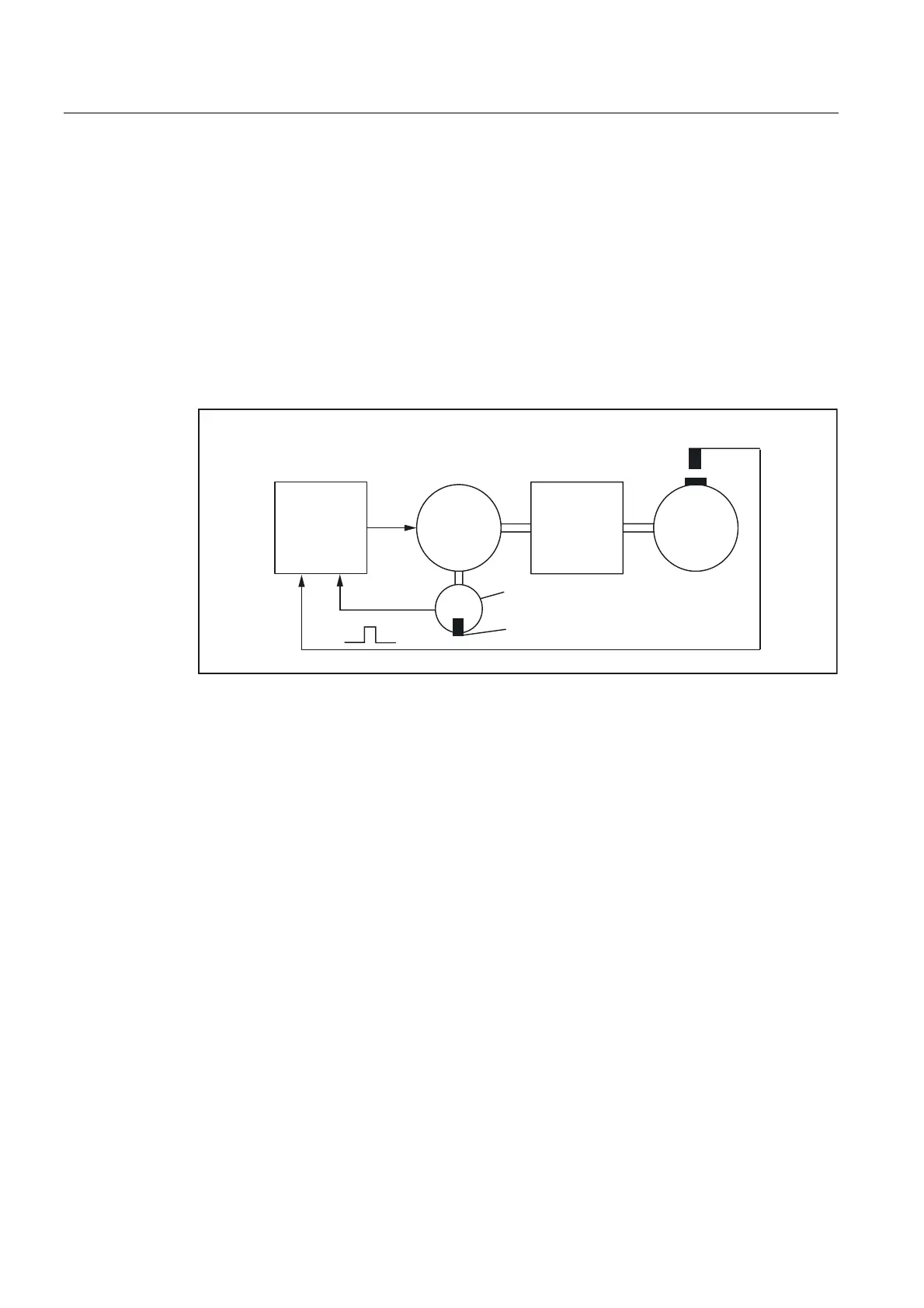

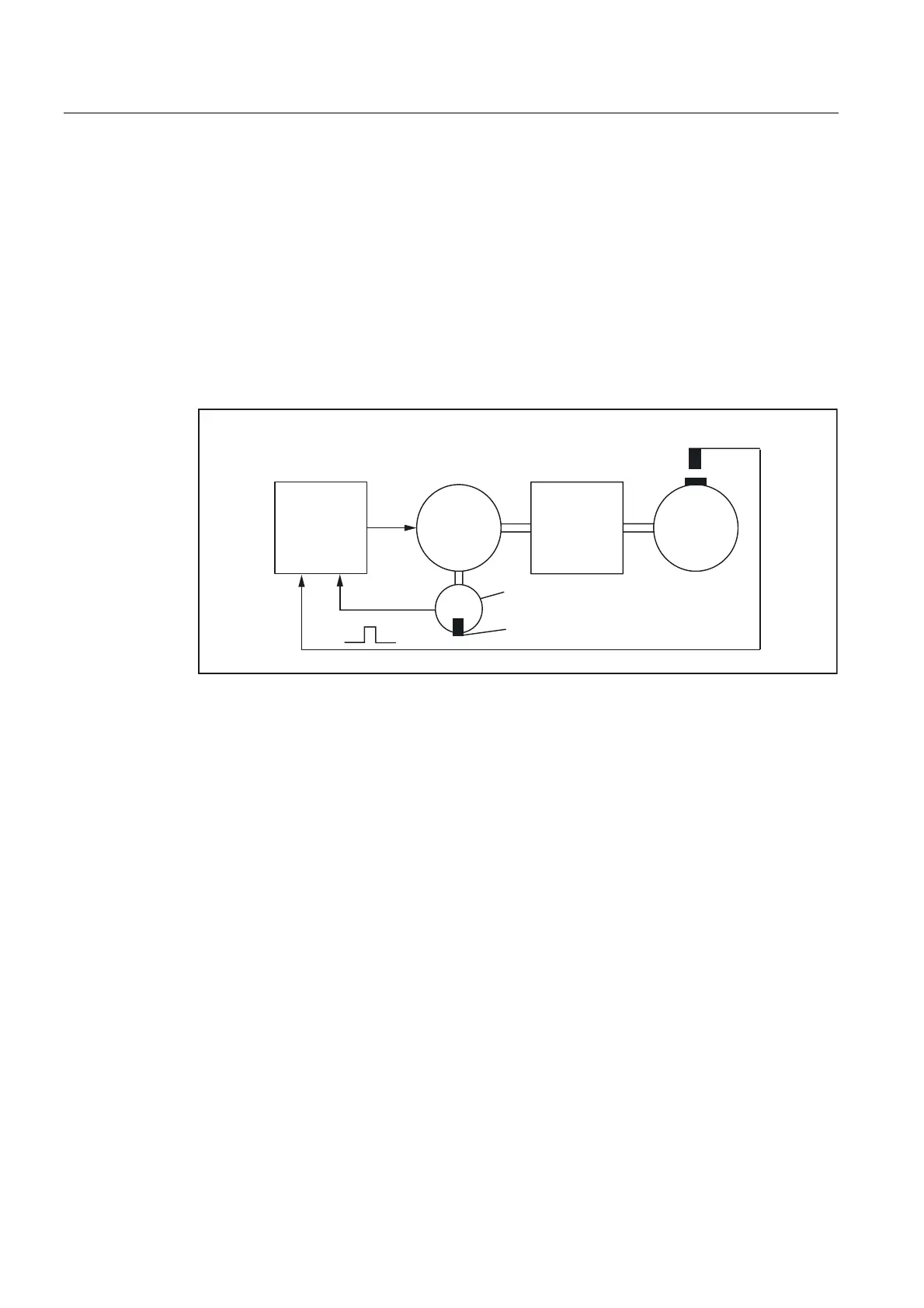

Referencing of incremental measuring systems is based on the unique position of the

encoder zero mark relative to the overall traversing range of the machine axis. If several

encoder zero marks are detected in the traversing range of the machine axis due to

machine-specific factors, e.g., reduction gear between encoder and load, a BERO must be

mounted on the machine and connected to the relevant drive module (SIMODRIVE 611D)

via a BERO input in order to uniquely specify the reference point. The position of the

reference point is then derived from the combination of BERO signal and encoder zero mark.

'ULYH

3RVLWLRQ

0RWRU

*HDU

/RDG

6SLQGOH

0HDVXULQJV\VWHP

=HURPDUN

%(52

Figure 2-13 Zero mark selection with BERO

Zero mark evaluation with BERO must be parameterized as the referencing mode:

MD34200 $MA_ENC_REFP_MODE = 5

Negative edge evaluation

In the case of a referencing operation with a negative edge evaluation of the BERO signal:

MD34120 $MA_REFP_BERO_LOW_ACTIVE = FALSE

synchronization is with the next encoder zero mark encountered after the BERO is exited.

Positive edge evaluation

In the case of a referencing operation with a positive edge evaluation of the BERO signal:

MD34120 $MA_REFP_BERO_LOW_ACTIVE = TRUE

synchronization is with the next encoder zero mark encountered after the BERO is

approached.

If, mechanically, the BERO is sized in such a way that the positive BERO signal covers the

entire width of the encoder zero mark, the encoder zero mark will be reliably detected in both

traversing directions.

Loading...

Loading...