Detailed description

2.1 Path feedrate F

Basic logic functions: Feeds (V1)

20 Function Manual, 11/2006, 6FC5397-0BP10-2BA0

2.1.4.2 Programmable run-in and run-out path for G33, G34 and G35

Application

]

[

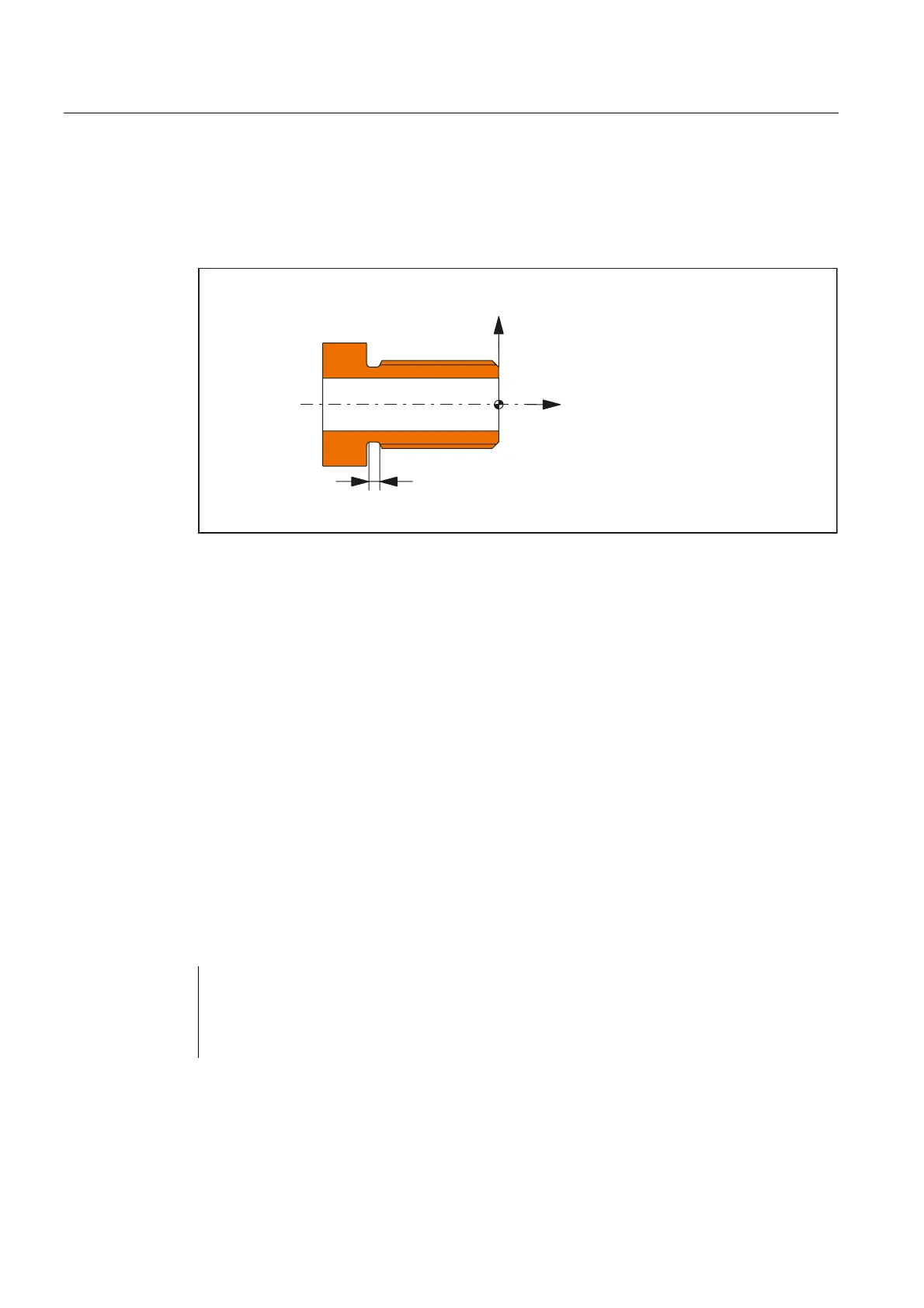

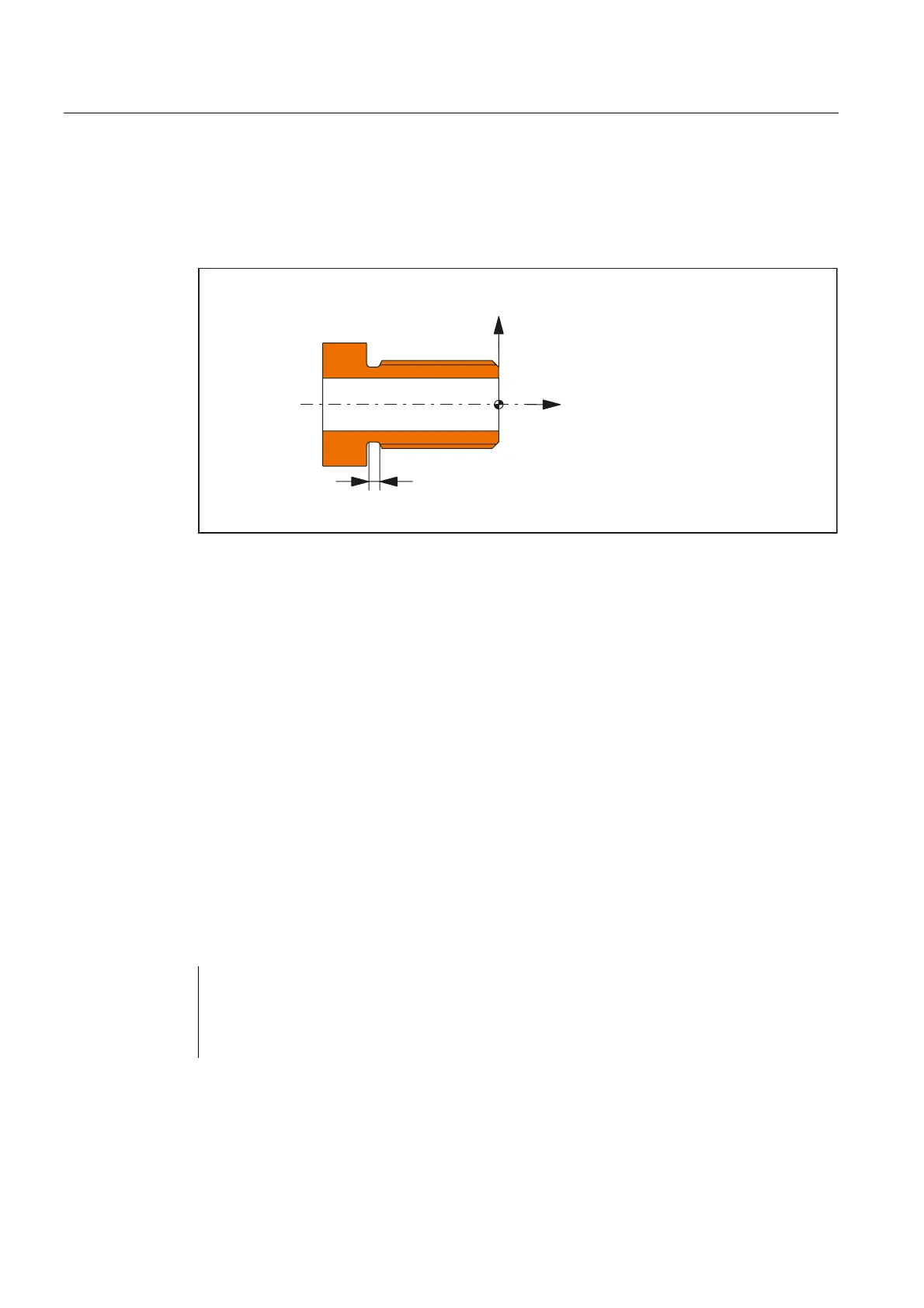

5XQLQRUUXQRXWSDWKDFFWRGLUHFWLRQRIPDFKLQLQJ

Figure 2-2 Runin or runout path too short

• Short run-in path

Due to the collar on the thread runin, little room is left for the tool (T) start ramp.

This must therefore be set shorter via DITS.

• Short run-out path

Due to the collar on the thread run-out, little room is left for the tool deceleration ramp,

leading to the risk of collision between the workpiece and the tool edge. The tool braking

ramp can be set shorter via DITE. Due to the inertia of the mechanical system, however,

a collision can nevertheless occur.

Remedy: Program a shorter thread, reduce the spindle speed.

The programmed runin and runout path only increases the rate of acceleration on the path. If

one of the two paths is set larger than the thread axis needs with active acceleration, the

thread axis is accelerated or decelerated with maximum acceleration.

Activation

The DITS and DITE functions are always active during thread cutting.

Example:

N...

N59 G90 G0 Z100 X10 SOFT M3 S500

N60 G33 Z50 K5 SF=180 DITS=1 DITE=3

; Start of corner rounding with

Z=53

N61 G0 X20

Loading...

Loading...