Detailed Description

2.4 Tool radius compensation 2D (TRC)

Basic logic functions: Tool Offset (W1)

82 Function Manual, 11/2006, 6FC5397-0BP10-2BA0

2.4.8 Collision detection and bottleneck detection

Collision detection

Collision detection (bottleneck detection) examines whether the equidistant paths of non-

consecutive blocks intersect. If an intersection is found, the response is the same as for

inside corners with multiple intersections: The last intersection to be found is valid:

The maximum number of blocks used for the predictive check can be entered in the machine

data:

MD20240 $MC_CUTCOM_MAXNUM_CHECK_BLOCKS (blocks for predictive contour

calculation for TRC).

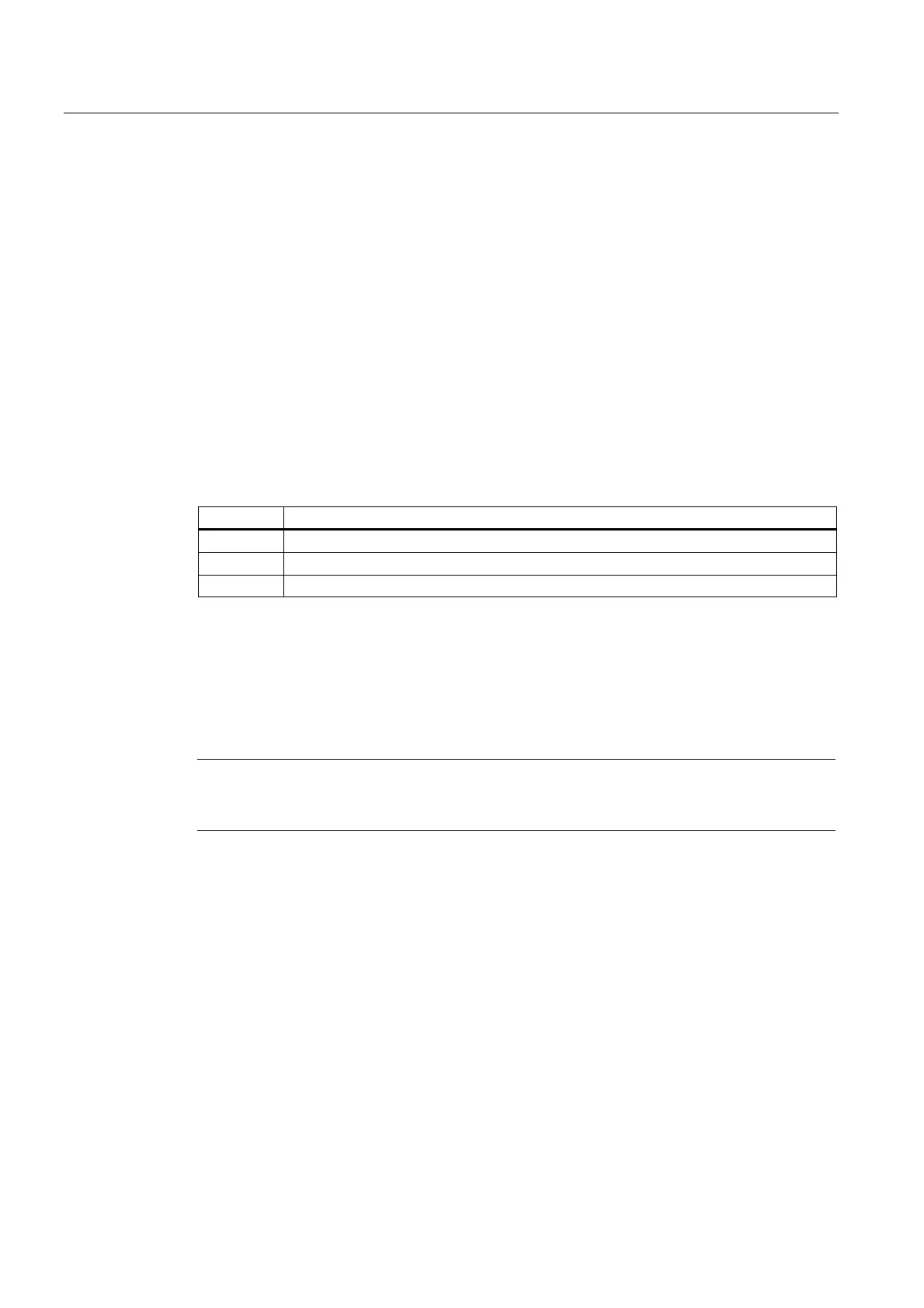

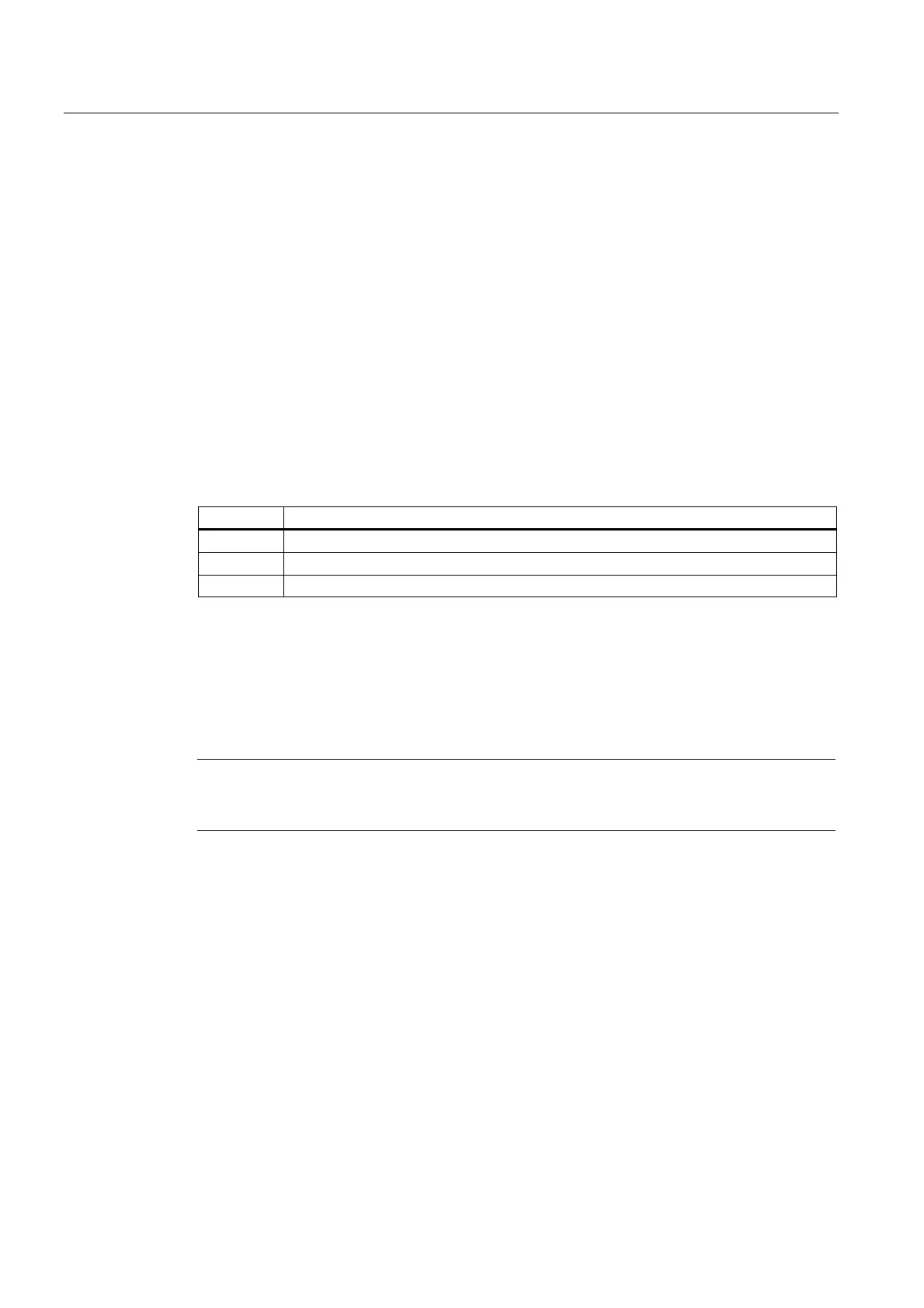

Programming

Collision detection can be activated or deactivated in the program:

Command Significance

CDON

Collision detection ON

CDOF

Collision detection OFF

CDOF2

Collision detection OFF

With CDOF, the search for an intersection initially examines two consecutive blocks. Other

blocks are not included in the search. If an intersection is found between adjacent blocks, no

further blocks are examined. With outside corners, an intersection can always be found

between two consecutive blocks.

Predictive examination of more than two adjacent blocks is thus possible with CDON and

CDOF.

Note

CDOF2 is only effective for 3D peripheral milling and has the same significance as CDOF for

all other types of machining (e.g., 3D face milling).

Omission of block

If an intersection is detected between two blocks, which are not consecutive, none of the

motions programmed between these blocks on the compensation plane are executed. All

other motions and executable instructions (M commands, traversal of positioning axes, etc.)

contained in the omitted blocks are executed at the intersection position in the sequence, in

which they are programmed in the NC program.

Loading...

Loading...