Detailed description

2.3 Feedrate control

Basic logic functions: Feeds (V1)

50 Function Manual, 11/2006, 6FC5397-0BP10-2BA0

Interface signals

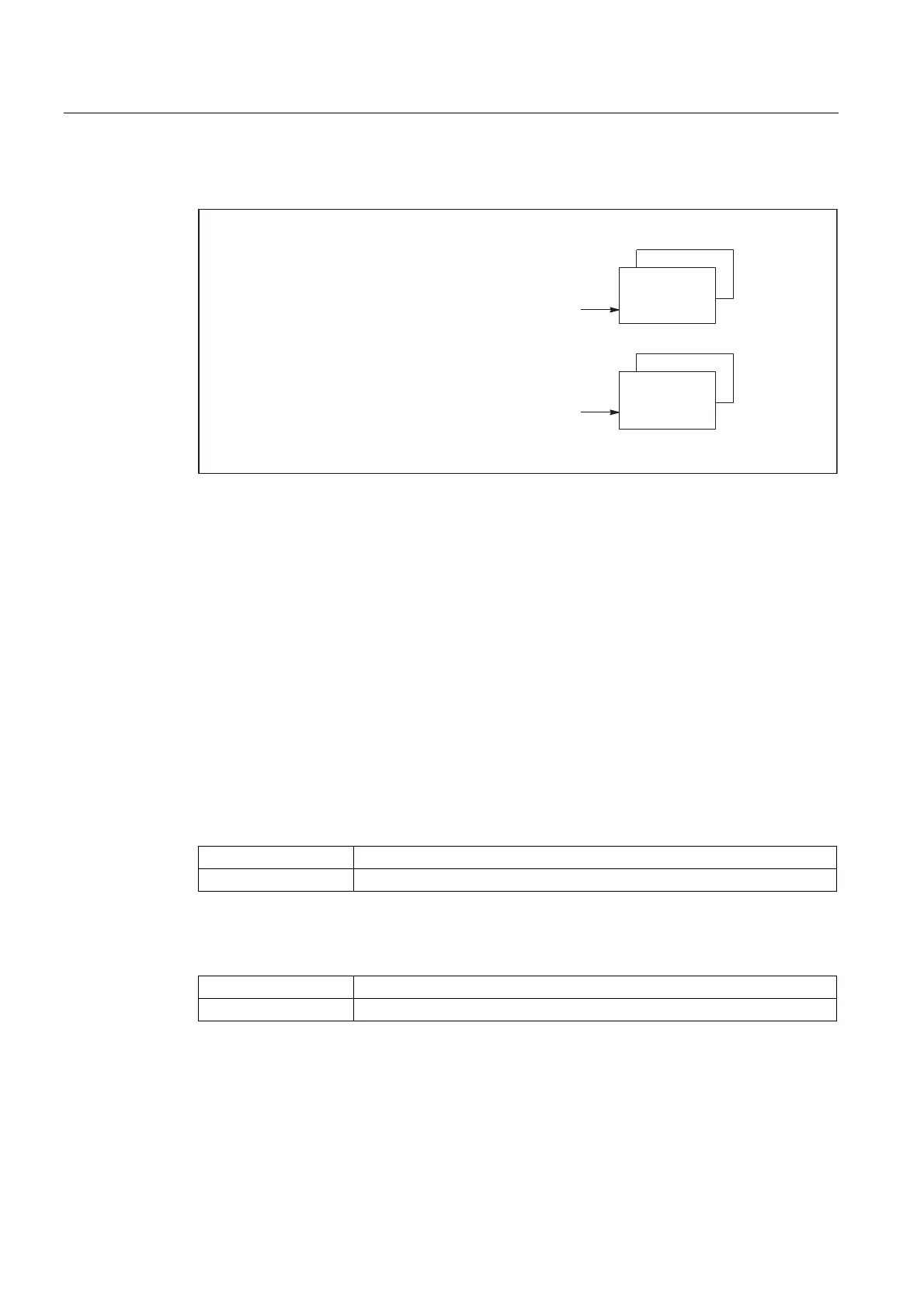

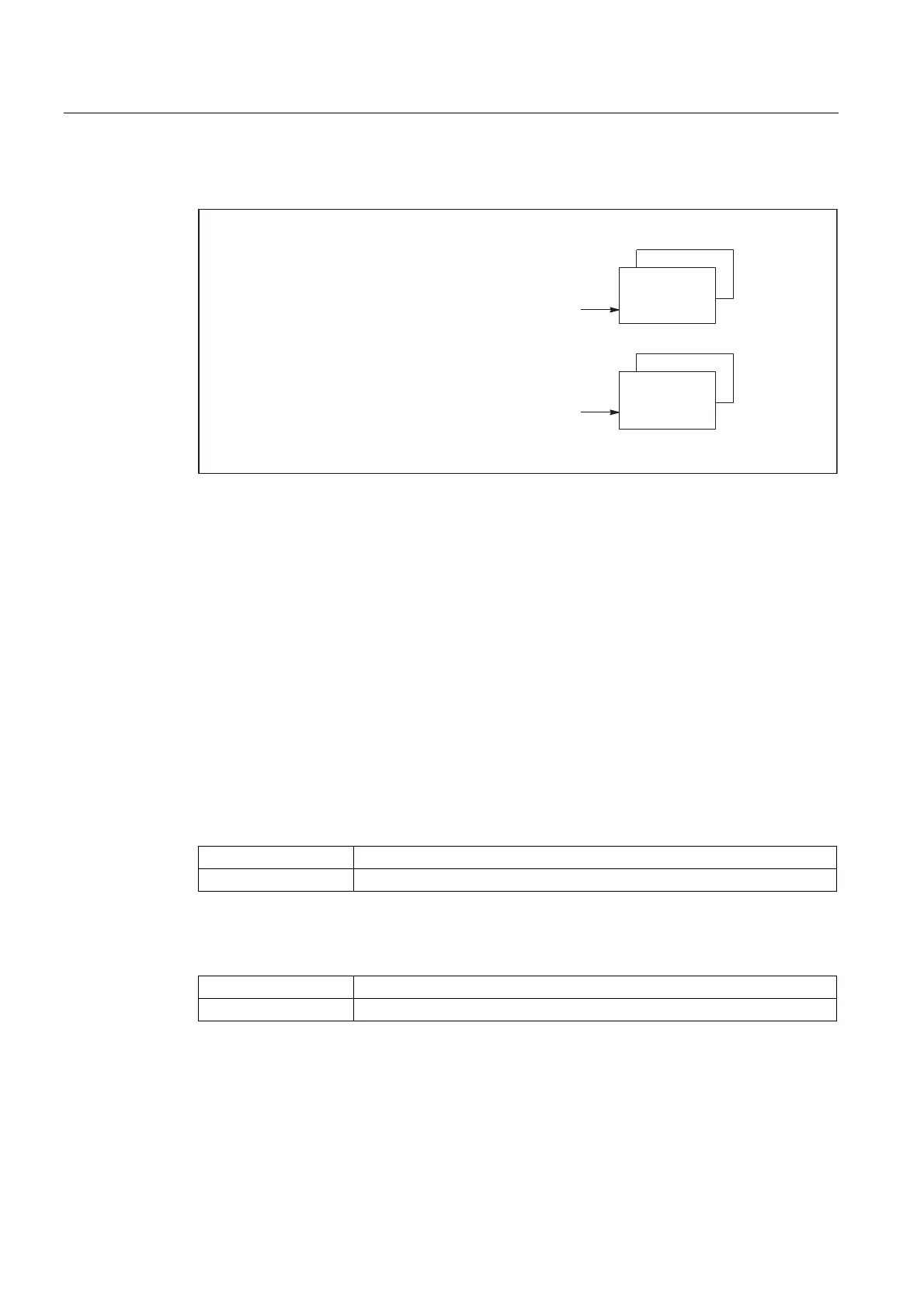

'%;

'%;

6LJQDOVWRFKDQQHO'%

$FWLYDWHIL[HGIHHGUDWHIRUSDWKJHRPHWU\D[HV

)L[HG

IHHGUDWH

&KDQQHO

&KDQQHO

6LJQDOVWRD[LV'%

$FWLYDWHIL[HGIHHGUDWHIRUPDFKLQHD[HV

)L[HG

IHHGUDWH

$[LV

$[LV

Figure 2-7 Overview of interface signals for fixed feedrate

2.3.8 Feedrate for chamfer/rounding FRC, FRCM

General

The machining conditions can change significantly during surface transitions to

chamfer/rounding. The chamfer/rounding contour elements therefore need their own

optimized feedrate values in order to achieve the required surface finish.

Function

You can program the feedrate for the chamfer/rounding with FRC (non-modal) or FRCM

(modal).

The feedrate value is interpreted according to the type of feedrate active:

G94, G961, G971: Feedrate in mm/min, inch/min or

o

/min

G95, G96, G97: Revolutional feedrate in mm/rev or inch/rev

The FRC/FRCM value is applied depending upon the machine data:

MD20201 CHFRND_MODE_MASK

Bit 0 = 0: FRC/FRCM from following block (default setting)

Bit 1 = 0: FRC/FRCM from preceding block (recommended setting)

Reason: The feedrate type (G94,G95,G96,G961 etc.) and thus the conversion to the

internal format must be consistent within the block for F and FRC/FRCM.

Loading...

Loading...