Detailed Description

2.9 Sum offsets and setup offsets

Basic logic functions: Tool Offset (W1)

162 Function Manual, 11/2006, 6FC5397-0BP10-2BA0

7RROFDUULHU

WRROFRPSRQHQW

7RRO

.LQHPDWLFWUDQVIRUPDWLRQ

WRROFRPSRQHQW

.LQHPDWLFWUDQVIRUPDWLRQ

ZRUNSLHFHWDEOHRUSDUWFRPSRQHQW

:&6

%&6

7&6

0&6

.&6

3

;

=

;

=

;

=

;

=

;

=

.

7

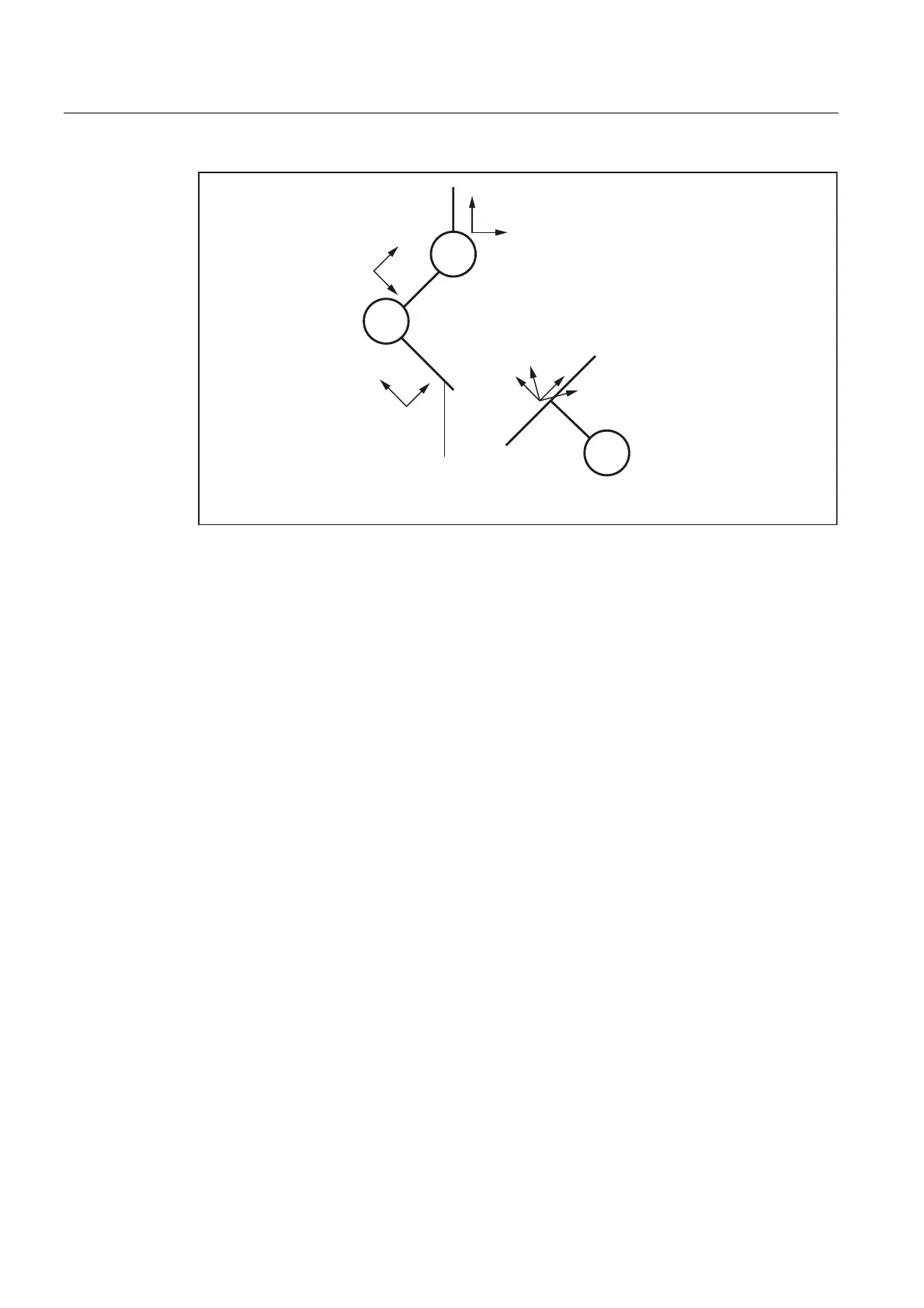

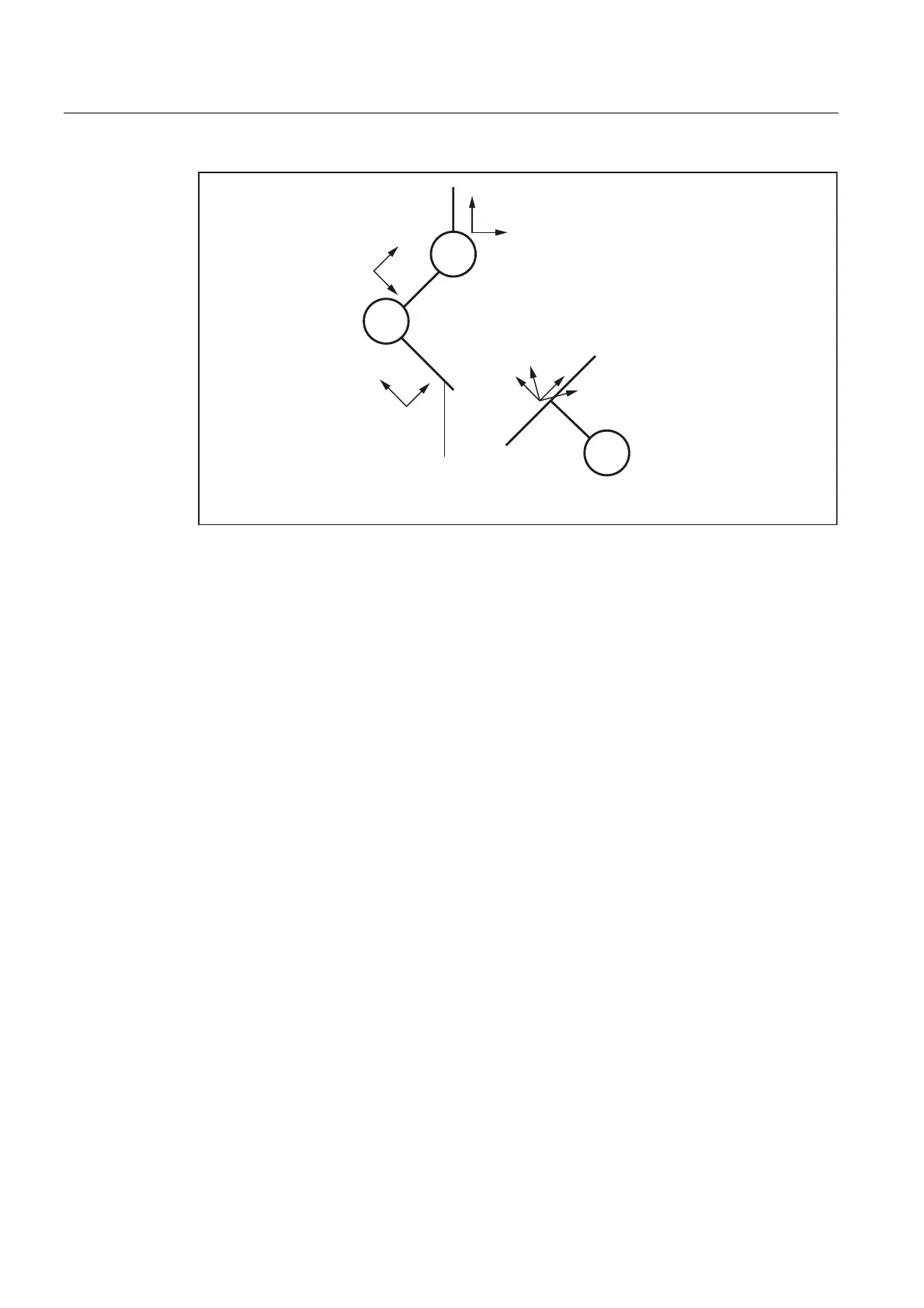

Figure 2-53 Coordinate system for the evaluation of tool lengths

2.9.5.2 Functionality of the individual wear values

TOWSTD

Initial setting (default behavior):

• The wear values are added to the other tool length components.

The resulting total tool length is then used in further calculations.

In the case of an active toolholder with orientation capability:

• The wear values are subjected to the appropriate rotation.

TOWMCS

Wear data in the MCS (machine coordinate system):

In the case of an active rotation by means of a toolholder with orientation capability:

• The toolholder only rotates the vector of the resultant tool length. Wear is ignored.

Then the tool length vector rotated in this way and the wear are added. The wear is not

subjected to the rotation.

If no toolholder with orientation capability is active or this does not result in a rotation,

TOWMCS and TOWSTD are identical.

Loading...

Loading...