Detailed Description

2.9 Sum offsets and setup offsets

Basic logic functions: Tool Offset (W1)

Function Manual, 11/2006, 6FC5397-0BP10-2BA0

161

Programming

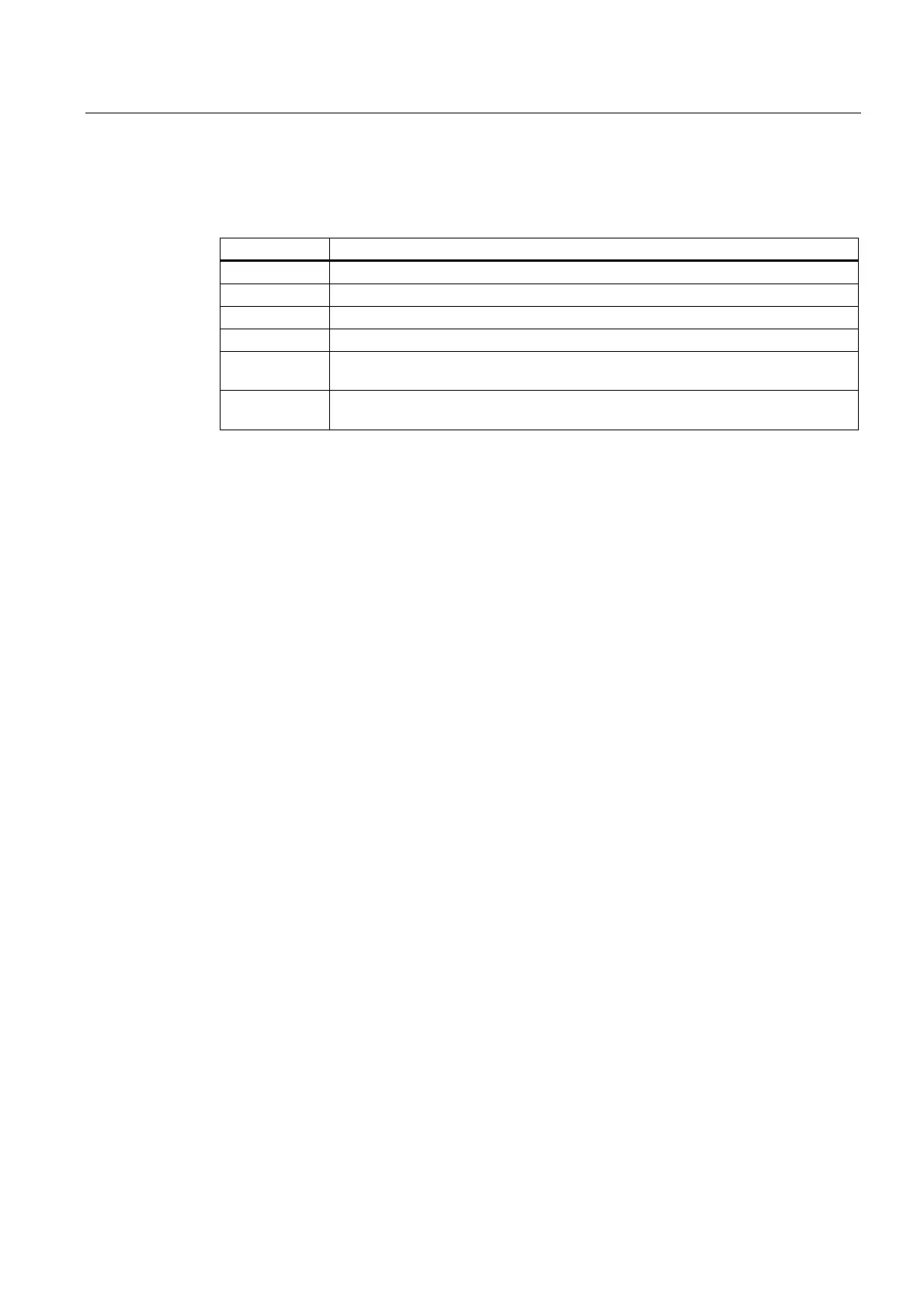

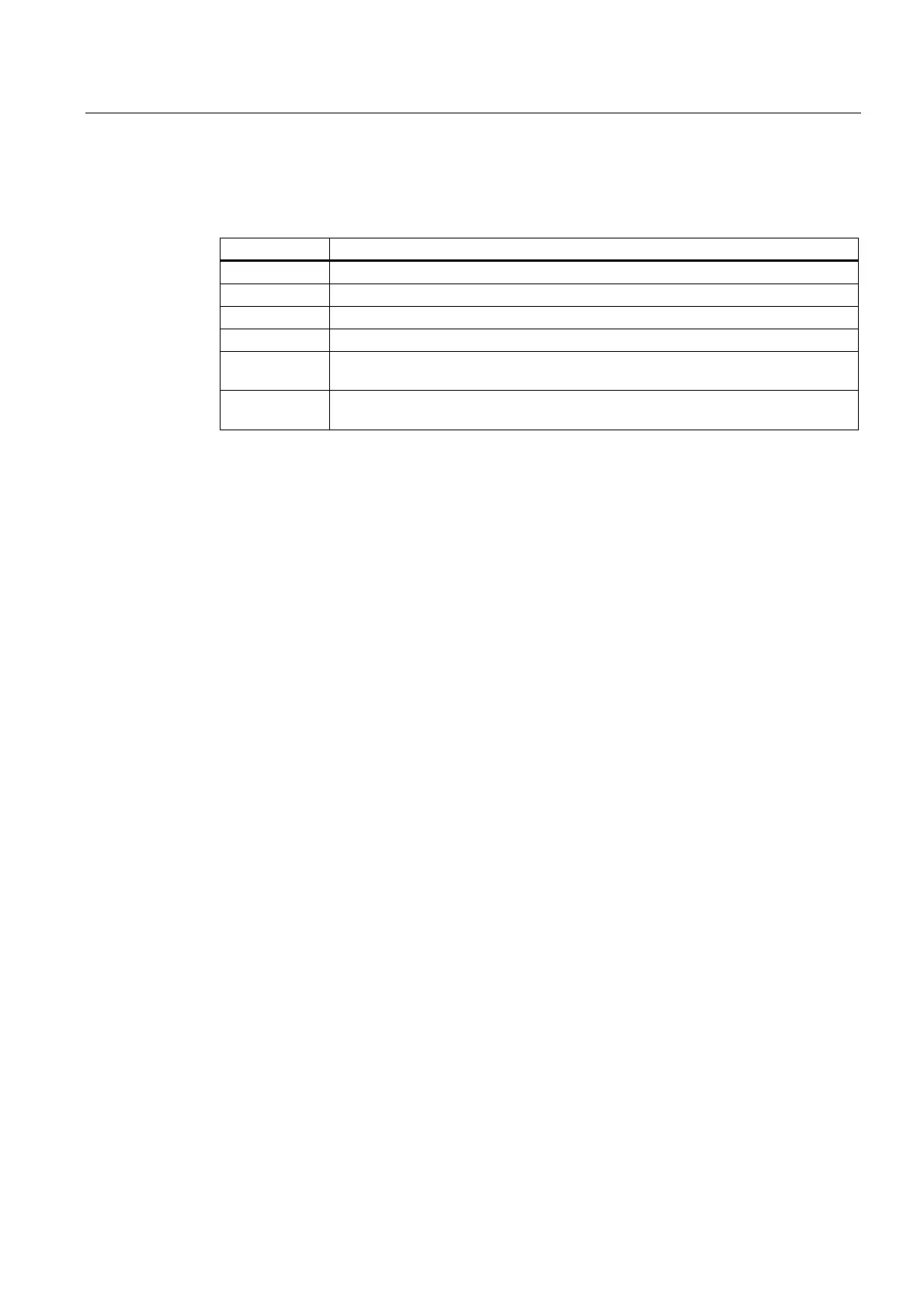

G-code group 56 can be used to define the following values:

Syntax Corrections

TOWSTD

Initial setting value for offsets in tool length

TOWMCS

Wear data in the machine coordinate system (MCS)

TOWWCS

Wear values in workpiece coordinate system (WCS)

TOWBCS

Wear values in basic coordinate system (BCS)

TOWTCS

Wear values in the TCS (Tool Coordinate System) at the toolholder (tool carrier

reference point T)

TOWKCS

Wear values in tool coordinate system for kinematic transformation (KCS) of tool

head

Coordinate systems for offsets in tool length

G codes TOWMCS, TOWWCS, TOWBCS, TOWTCS, and TOWKCS can be used, e.g., to measure

the wear tool length component in five different coordinate systems.

1. Machine coordinate system

MCS

1. Basic Coordinate System

BCS

1. Workpiece coordinate system

WCS

1. Tool coordinate system of kinematic transformation

KCS

1. Tool coordinate system

TCS

The calculated tool length or a tool length component can be represented and read out in

one of these coordinate systems using the GETTCOR function (predefined subprogram).

References:

/FB1/ Function Manual Basic Functions; Tool Offset (W1),

Section: Read tool lengths, tool length components

Loading...

Loading...