Detailed Description

2.4 Tool radius compensation 2D (TRC)

Basic logic functions: Tool Offset (W1)

52 Function Manual, 11/2006, 6FC5397-0BP10-2BA0

Why TRC?

The contour (geometry) of the workpiece programmed in the part program should be

independent of the tools used in production. This makes it necessary to draw the values for

the tool length and tool radius from a current offset memory. Tool radius compensation can

be used to calculate the equidistant path to the programmed contour from the current tool

radius.

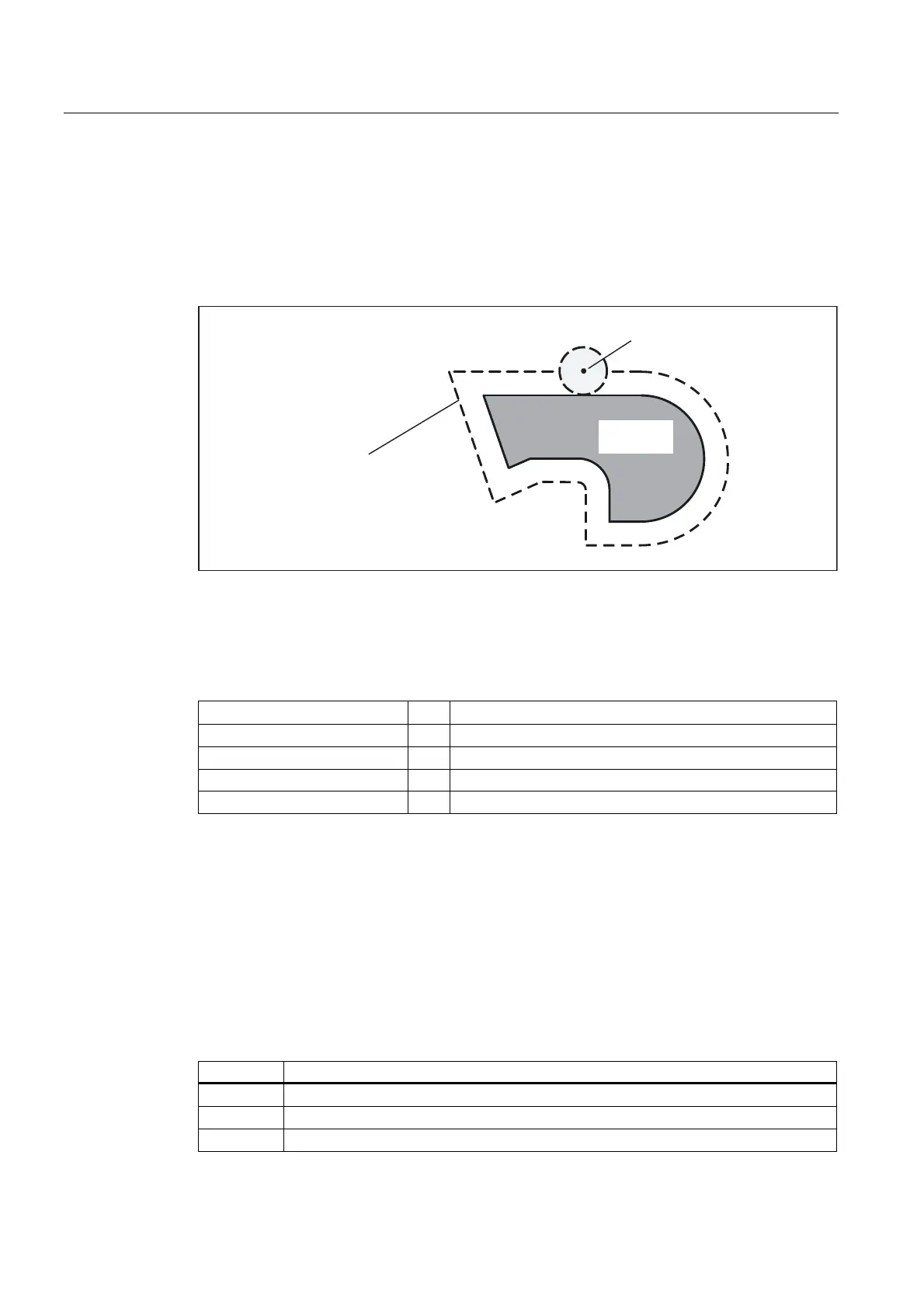

7RRO

3DWKRIWKHWRROFHQWHUSRLQW

DWHTXDOGLVWDQFHWRWKH

FRQWRXUHTXLGLVWDQWSDWK

:RUNSLHFH

FRQWRXU

Figure 2-15 Workpiece contour (geometry) with equidistant path

TRC on the plane

TRC is active on the current plane (G17 to G19) for the following types of interpolation:

• Linear interpolation

...

G0,G1

• Circular interpolation

...

G2, G3, CIP

• Helical interpolation

...

G2,G3

• Spline interpolation

...

ASPLINE, BSPLINE, CSPLINE

• Polynomial interpolation

...

POLY

2.4.2 Selecting the TRC (G41/G42)

Direction of compensation

TRC calculates a path, which is equidistant to the programmed contour. Compensation can

be performed on the left- or righthand side of the programmed contour in the direction of

motion.

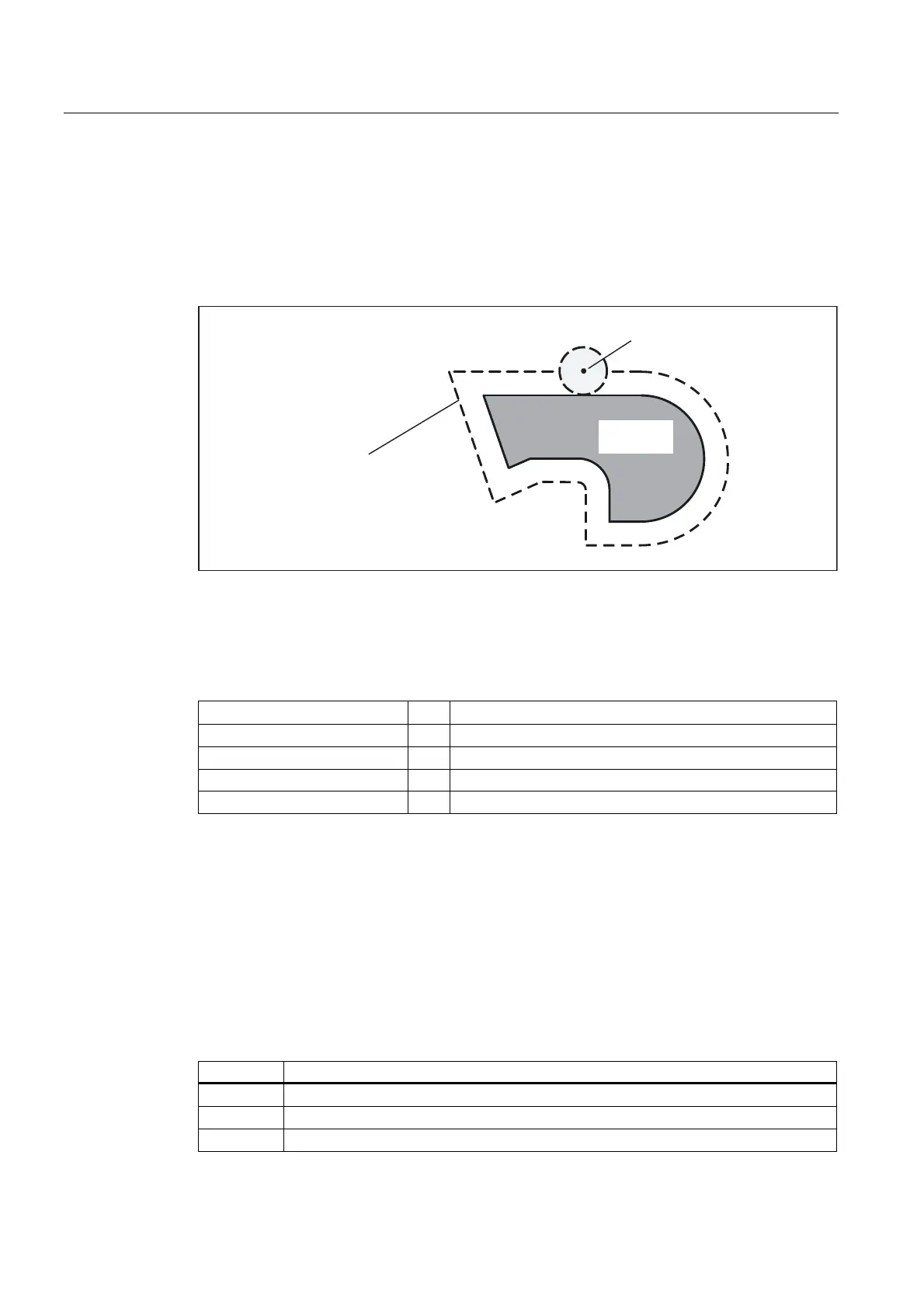

Command Significance

G41

TRC on the lefthand side of the contour in the direction of motion

G42

TRC on the righthand side of the contour in the direction of motion

G40

Deselection of TRC

Loading...

Loading...