Detailed description

2.4 Referencing with incremental measurement systems

Basic logic functions: Reference Point Approach (R1)

14 Function Manual, 11/2006, 6FC5397-0BP10-2BA0

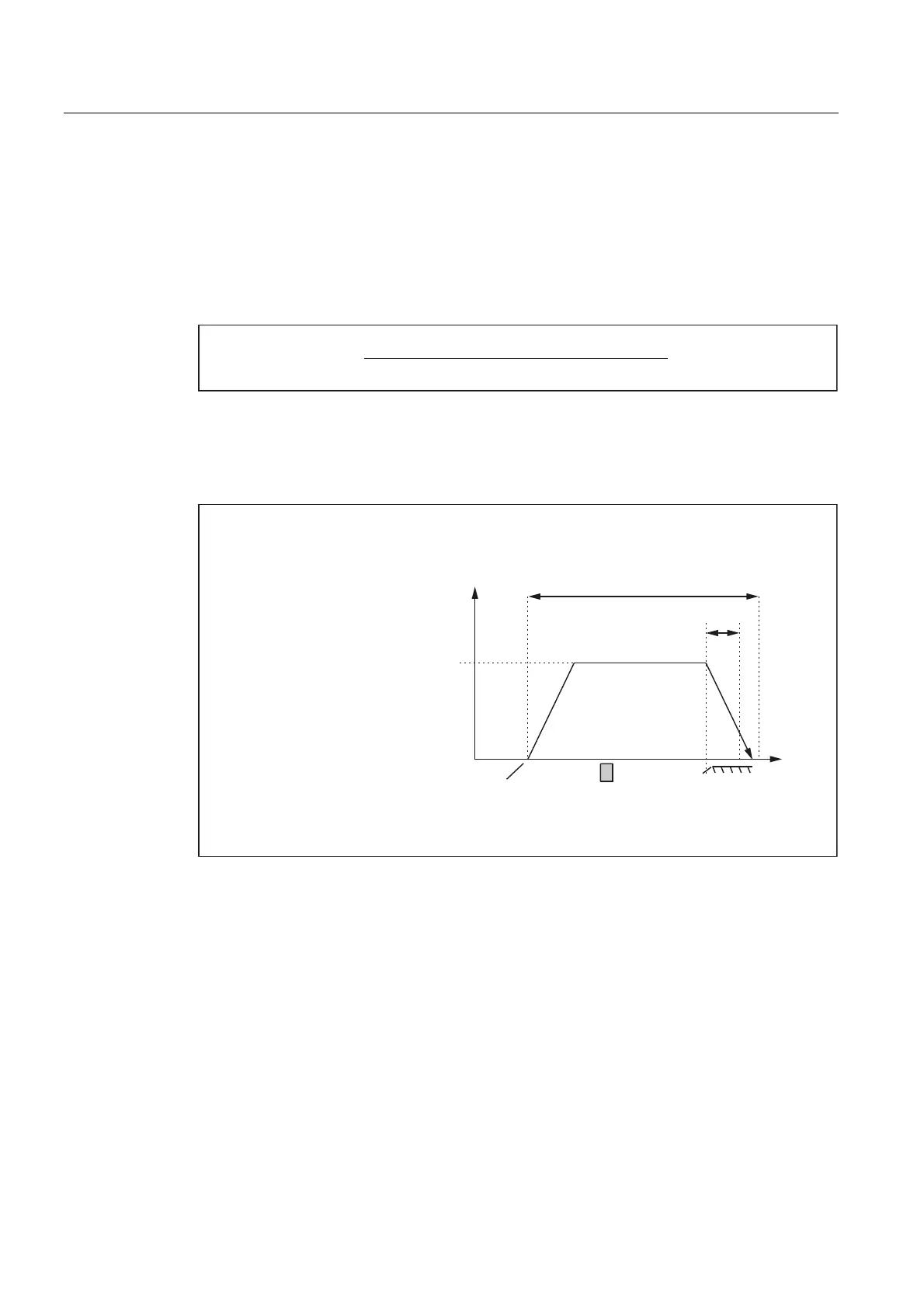

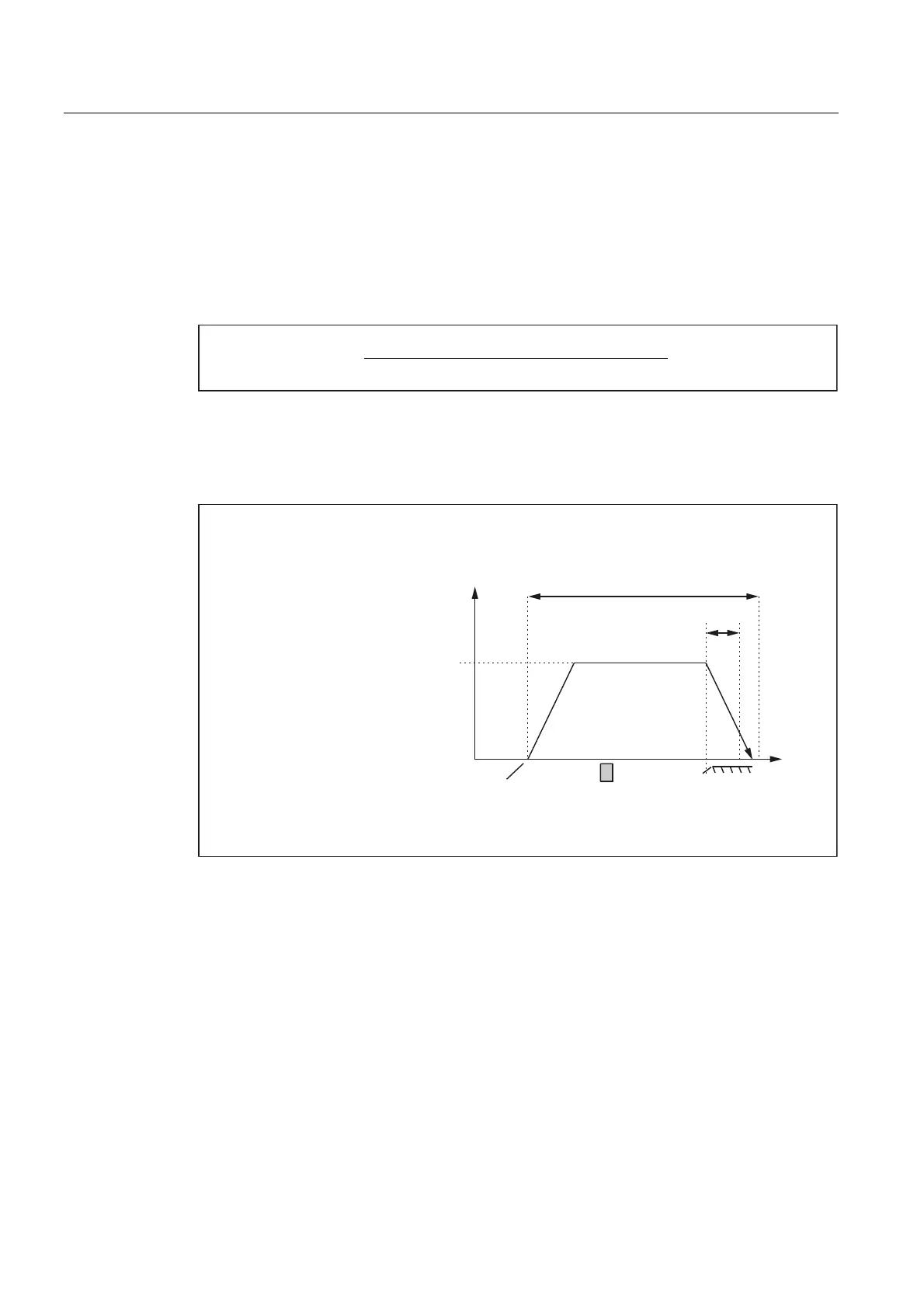

MD34020 $MA_REFP_VELO_SEARCH_CAM (Reference point approach velocity)

The PLC user program communicates to the NC that the reference cam has been reached

via the following interface signal:

DB31, ... DBX12.7 (reference point approach deceleration)

As a result the NC decelerates to zero speed. The following distance s

min

is still minimally

back tracked:

60,1

0'0$B5()3B9(/2B6($5&+B0$5.(5

0'0$B0$;B$;B$&&(/

This minimum distance is required to ensure that the machine axis exits the reference cam in

Phase 2 at the parameterized reference point creep velocity.

Phase 1 is now complete. Reference point approach is continued with Phase 2.

5HIHUHQFHSRLQWDSSURDFKYHORFLW\

6WDUWLQJSRVLWLRQ

RID[LV

0LQLPXPGLVWDQFH

5HIHUHQFHSRLQWFDP

9HORFLW\

0D[LPXPGLVWDQFHWRUHIHUHQFHFDP

=HURPDUN

'LVWDQFH

0'0$B5()3B0$;B&$0B',67

0'0$B5()3B9(/2B6($5&+B&$0

Figure 2-3 Minimum distance for deceleration

Case 2: The machine axis is positioned on the reference cam

The machine axis remains at its starting position.

Phase 1 is now complete. Reference point approach is continued with Phase 2.

Case 3: The machine axis has no reference cam

Machine axes without reference point cams remain at their starting position.

These include, for example:

• Machine axes that only have one zero mark along their entire traversing range

• Rotary axes that only have one zero mark per revolution

Loading...

Loading...