Detailed description

2.4 Referencing with incremental measurement systems

Basic logic functions: Reference Point Approach (R1)

Function Manual, 11/2006, 6FC5397-0BP10-2BA0

17

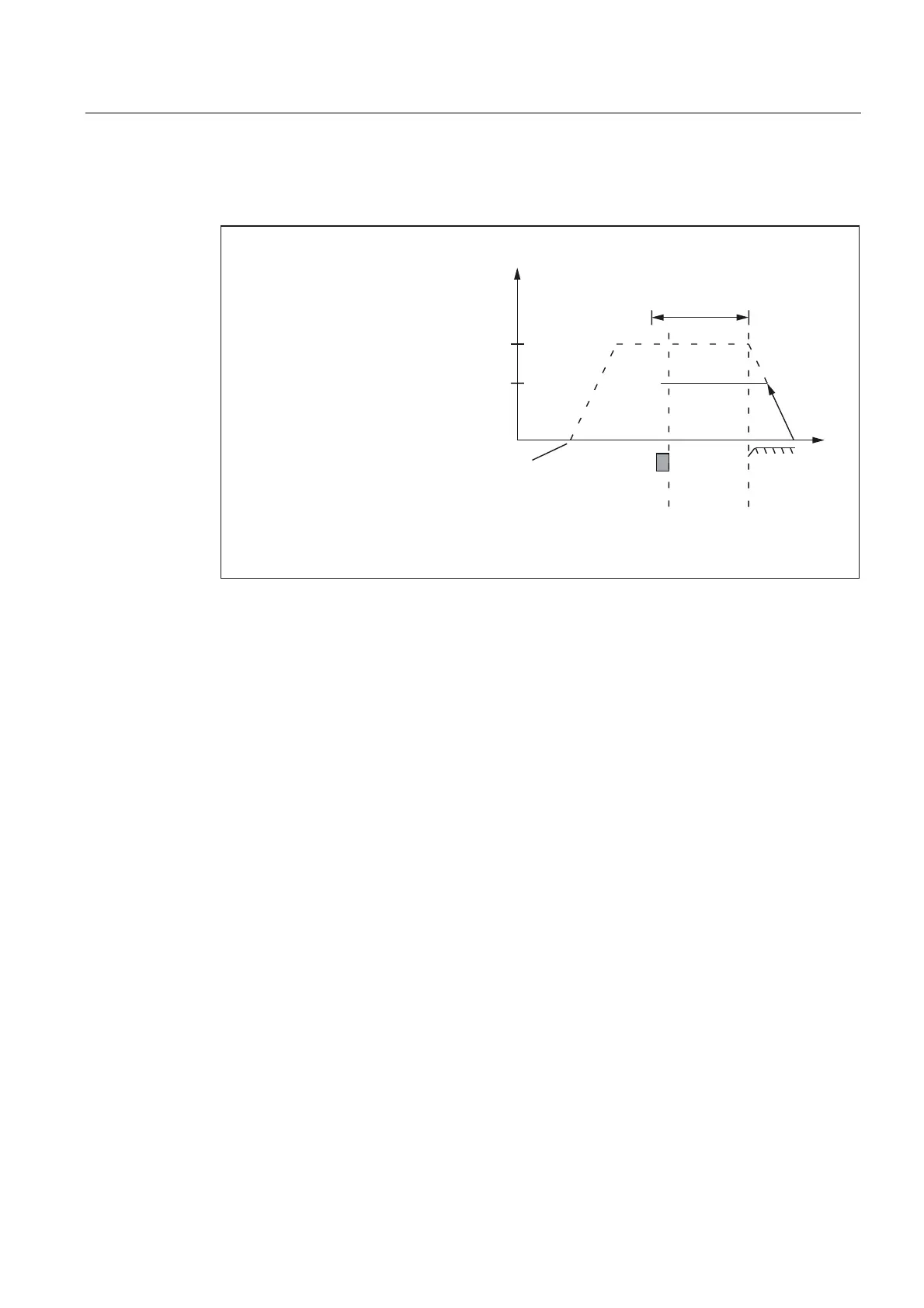

As soon as the encoder zero mark is detected, Phase 2 comes to an end. The machine axis

continues at constant velocity and reference point approach is continued with phase 3.

5HIHUHQFHSRLQWDSSURDFKYHORFLW\

6WDUWLQJSRVLWLRQ

RID[LV

5HIHUHQFH

SRLQWFDP

'HFHOHUDWLRQ

5HIHUHQFHSRLQW

DSSURDFK

9HORFLW\

5HIHUHQFHSRLQWFUHHSYHORFLW\

=HUR

0DUN

0D['LVWDQFHWRUHIHUHQFHPDUN

'LVWDQFH

0'0$B5()3B0$;B0$5.(5B',67

0'0$B5()3B9(/2B6($5&+B0$5.(5

0'0$B5()3B9(/2B6($5&+B&$0

Figure 2-5 Synchronization with falling reference cam signal edge

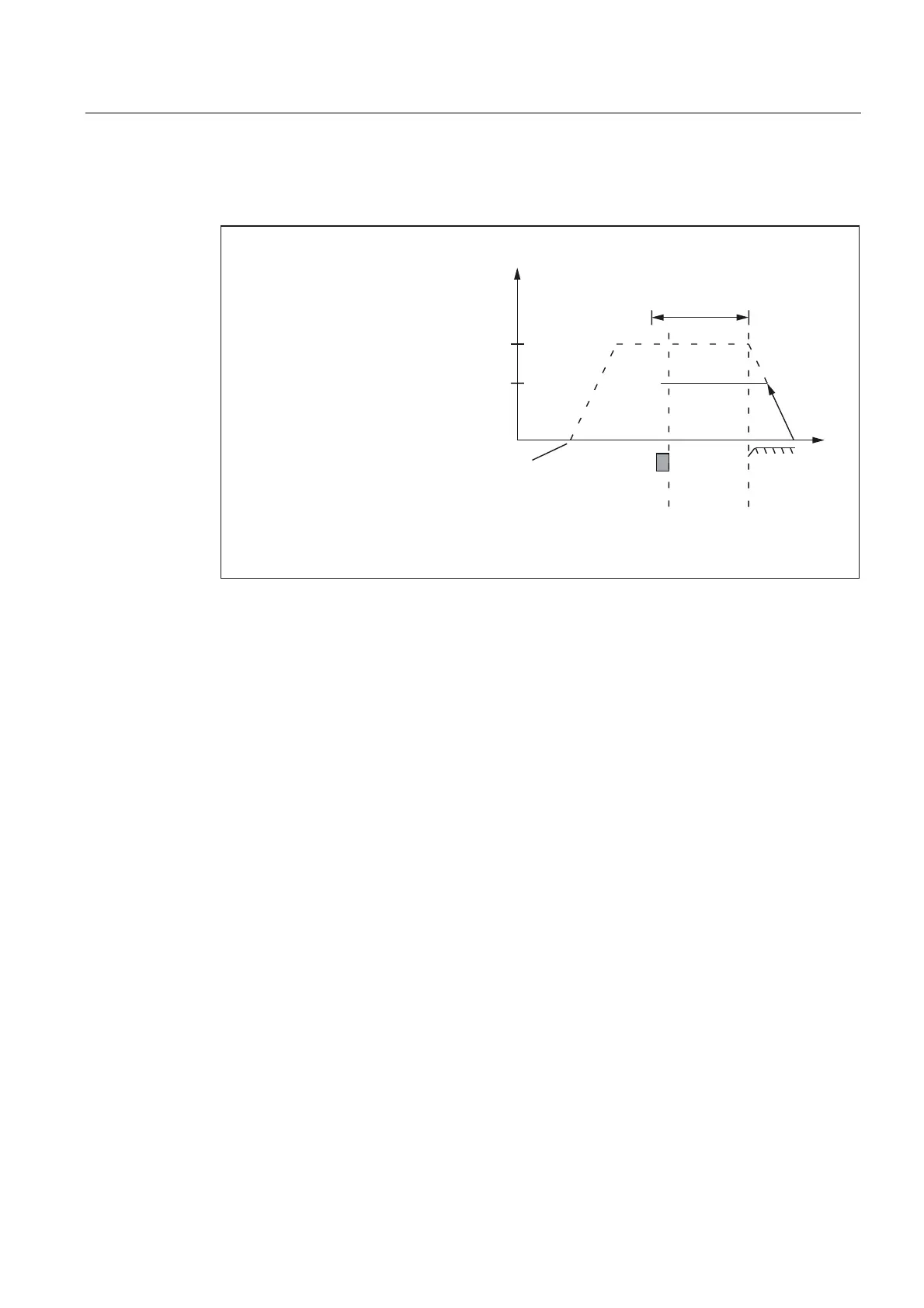

Case 2: Synchronization with rising reference cam edge

During synchronization with rising reference cam signal edge, the machine axis accelerates

to the parameterized reference point approach velocity against the parameterized reference

point approach direction (traversing direction of the phase 1):

MD34020 $MA_REFP_VELO_SEARCH_CAM (Reference point approach velocity)

MD34010 $MA_REFP_CAM_DIR_IS_MINUS (Reference point approach in minus direction)

After the reference cam is exited (DB31, ... DBX12.7 = 0), the machine axis is decelerated to

stillstand.

The machine axis then travels back to the reference cam at the parameterized reference

point creep velocity:

MD34040 $MA_REFP_VELO_SEARCH_MARKER (reference point creep velocity)

After the reference cam is reached (DB31, ... DBX12.7 = 1), the next encoder zero mark is

awaited.

As soon as the encoder zero mark is detected, Phase 2 comes to an end. The machine axis

continues at constant velocity and reference point approach is continued with phase 3.

Loading...

Loading...