Detailed Description

2.6 Spindle monitoring

Basic logic functions: Spindles (S1)

92 Function Manual, 11/2006, 6FC5397-0BP10-2BA0

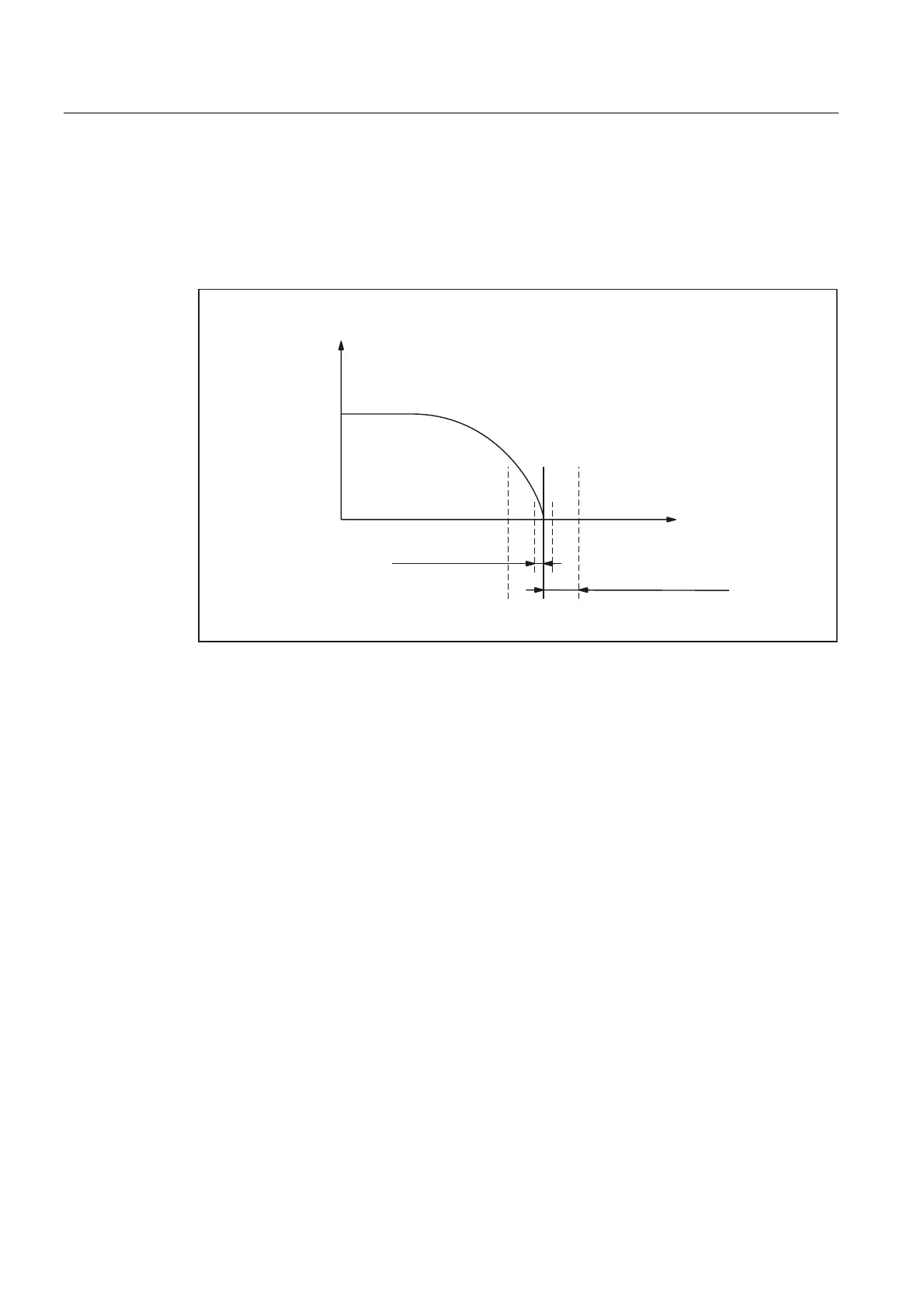

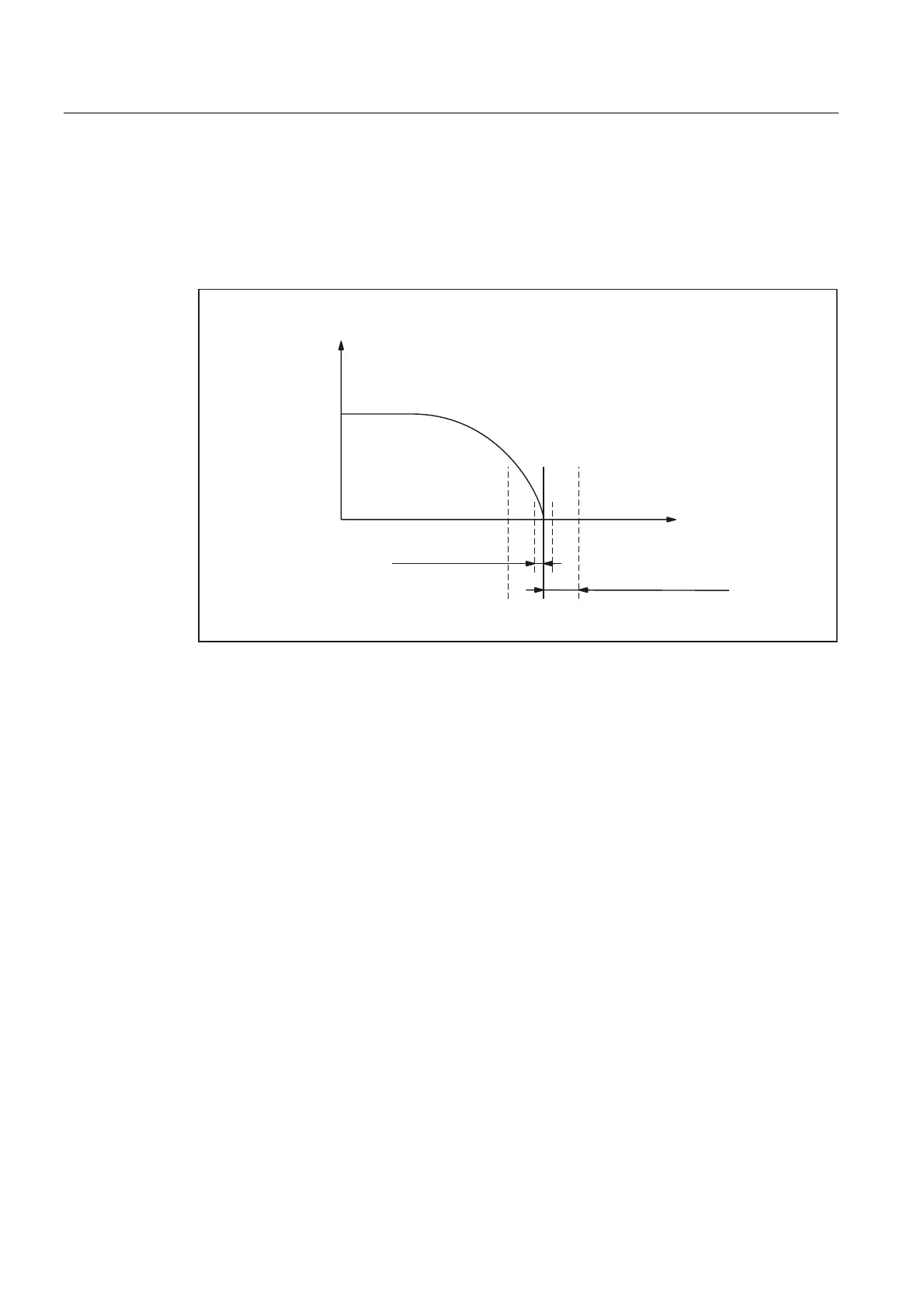

Exact stop window dependent on parameter set

Various parameter-set-dependent exact stop windows can be configured.

This makes it possible to work to different levels of accuracy in axis mode and spindle

positioning. The exact stop window can be configured separately for each gear step for

spindle positioning.

6SLQGOHVSHHG

([DFWVWRSOLPLWILQH

([DFWVWRSOLPLWFRDUVH

3RVLWLRQ

3RVLWLRQVHWSRLQW

Figure 2-12 Exact stop zones of a spindle

DB31, ... DBX60.7 and DB31, ... DBX60.6 (position reached with exact stop coarse / fine)

The two limit values defined by machine data:

MD36000 $MA_STOP_LIMIT_COARSE (Exact stop limit coarse)

and

MD36010 $MA_STOP_LIMIT_FINE (Exact stop limit fine)

are output to the PLC using NC/PLC IS:

DB31, ... DBX60.7 (Position reached with exact stop coarse)

and

DB31, ... DBX60.6 (Position reached with exact stop fine).

Block change for SPOS and M19

When positioning the spindle with SPOS or M19 the block is changed

dependent on end point monitoring with NC/PLC IS:

DB31, ... DBX60.6 (Position reached with exact stop fine).

All other functions programmed in the block must have achieved their end criterion (e.g., all

auxiliary functions acknowledged by the PLC).

With SPOSA, the block change does not depend on the monitoring of the end point.

Loading...

Loading...