Detailed Description

2.9 Sum offsets and setup offsets

Basic logic functions: Tool Offset (W1)

Function Manual, 11/2006, 6FC5397-0BP10-2BA0

147

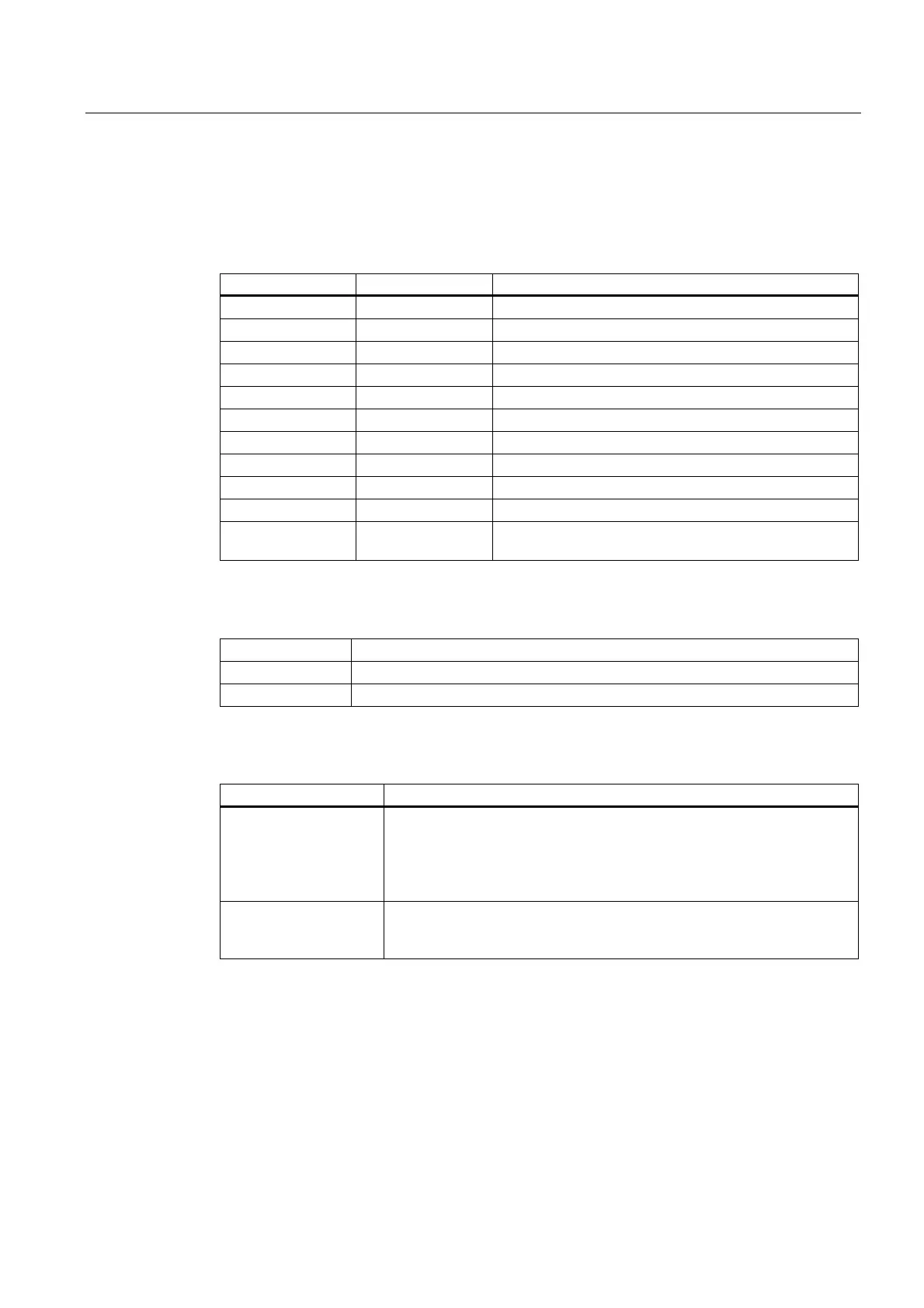

Parameters for geometry and wear

Tool geometry compensations are assigned to system variables $TC_DP3 to $TC_DP11.

System variables $TC_DP12 to $TC_DP20 allow you to name a wear for each of these

parameters.

Geometry Wear Length compensations

$TC_DP3 $TC_DP12 Length 1

$TC_DP4 $TC_DP13 Length 2

$TC_DP5 $TC_DP14 Length 3

Geometry Wear Radius compensation

$TC_DP6 $TC_DP15 Radius

$TC_DP7 $TC_DP16 Corner radius (tool type 700; slotting saw)

Geometry Wear Further compensations

$TC_DP8 $TC_DP17 Length 4 (tool type 700; slotting saw)

$TC_DP9 $TC_DP18 Length 5

$TC_DP10 $TC_DP19 Angle 1 (angle between face of tool and torus surface)

$TC_DP11 $TC_DP20 Angle 2 (angle between tool longitudinal axis and upper

end of torus surface)

Tool base dimension/adapter dimension

$TC_DP21 Adapter length 1

$TC_DP22 Adapter length 2

$TC_DP23 Adapter length 3

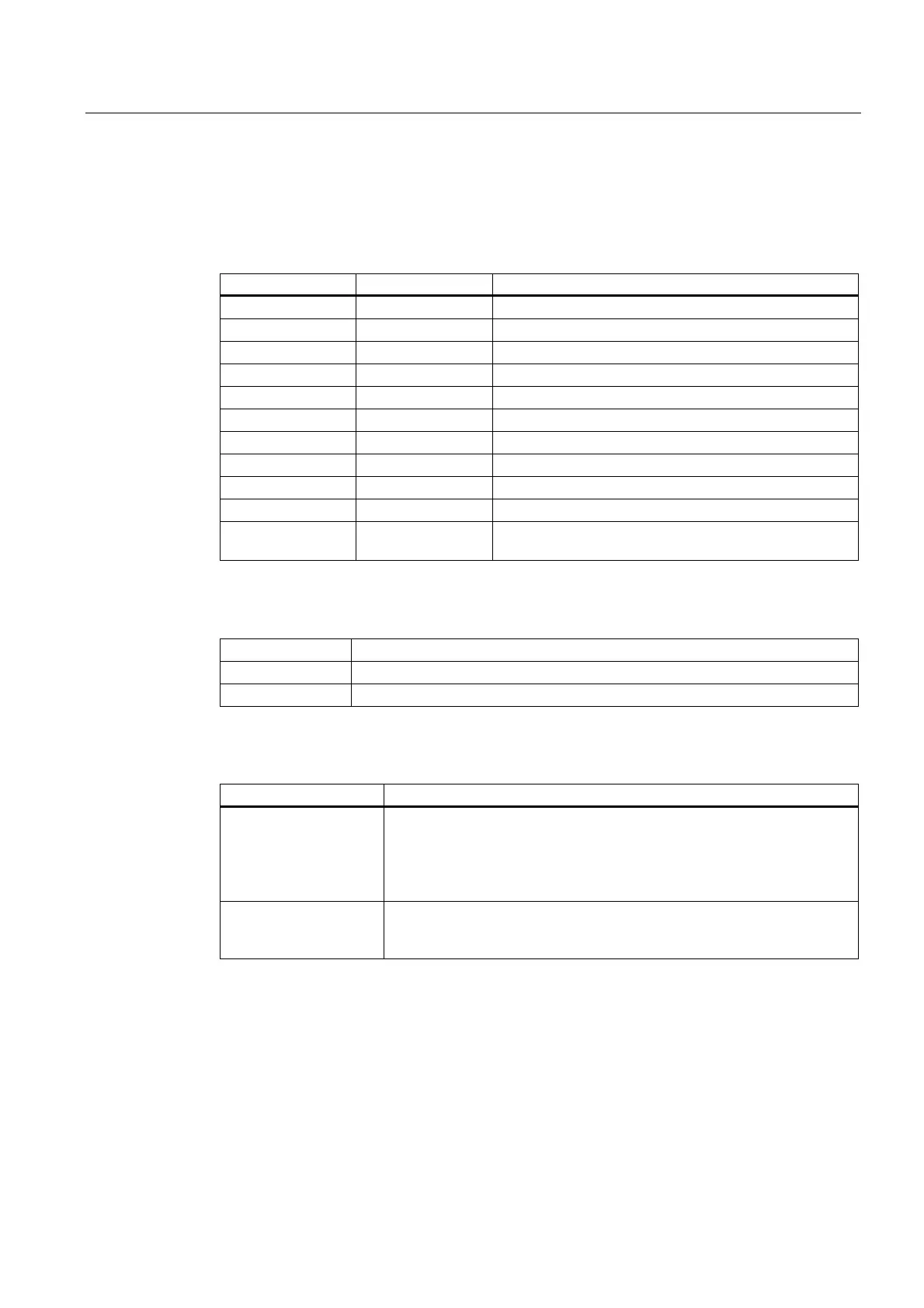

Technology

System variable Clearance angle

$TC_DP24

• The clearance angle is stored here for ManualTurn; tool type 5xx.

Same significance as in standard cycles for turning tools.

• The tip angle of the drill is stored here for ShopMill; tool type 2xx.

• Used in standard cycles for turning tools; tool type 5xx. This is the

angle at the secondary cutting edge for these tools.

$TC_DP25

• The value for the cutting rate is stored here for ManualTurn.

• A bitcoded value for various states of tool types 1xx and 2xx is stored

here for ShopMill.

Loading...

Loading...