Detailed Description

2.9 Sum offsets and setup offsets

Basic logic functions: Tool Offset (W1)

164 Function Manual, 11/2006, 6FC5397-0BP10-2BA0

TOWTCS

Wear values in TCS (tool coordinate system):

• If a toolholder with orientation capability is active, the tool vector is calculated as for

TOWMCS, without taking the wear into account.

• The wear data are interpreted in the tool coordinate system.

The wear vector in the TCS (Tool Coordinate System) is converted to the machine

coordinate system by way of the tool coordinate system of the kinematic transformation

(KCS) and added to the tool vector.

TOWKCS

The wear value specifications for the kinematic transformation are interpreted in the

associated TCS (Tool Coordinate System).

The wear vector is converted to the machine coordinate system by way of the tool coordinate

system of the kinematic transformation and added to the tool vector.

G code change when a tool is active

Changing the G code in the group TOWSTD, TOWMCS, TOWWCS, TOWBCS, TOWTCS, and

TOWKCS does not affect an already active tool, and does not become effective until the next

tool is selected.

A new G code of this group will also come into effect if it is programmed in the same block, in

which a tool is selected.

Evaluation of individual wear components

Evaluation of individual wear components (assignment to geometry axes, sign evaluation) is

influenced by:

• The active plane

• The adapter transformation

• The five setting data shown in the table below:

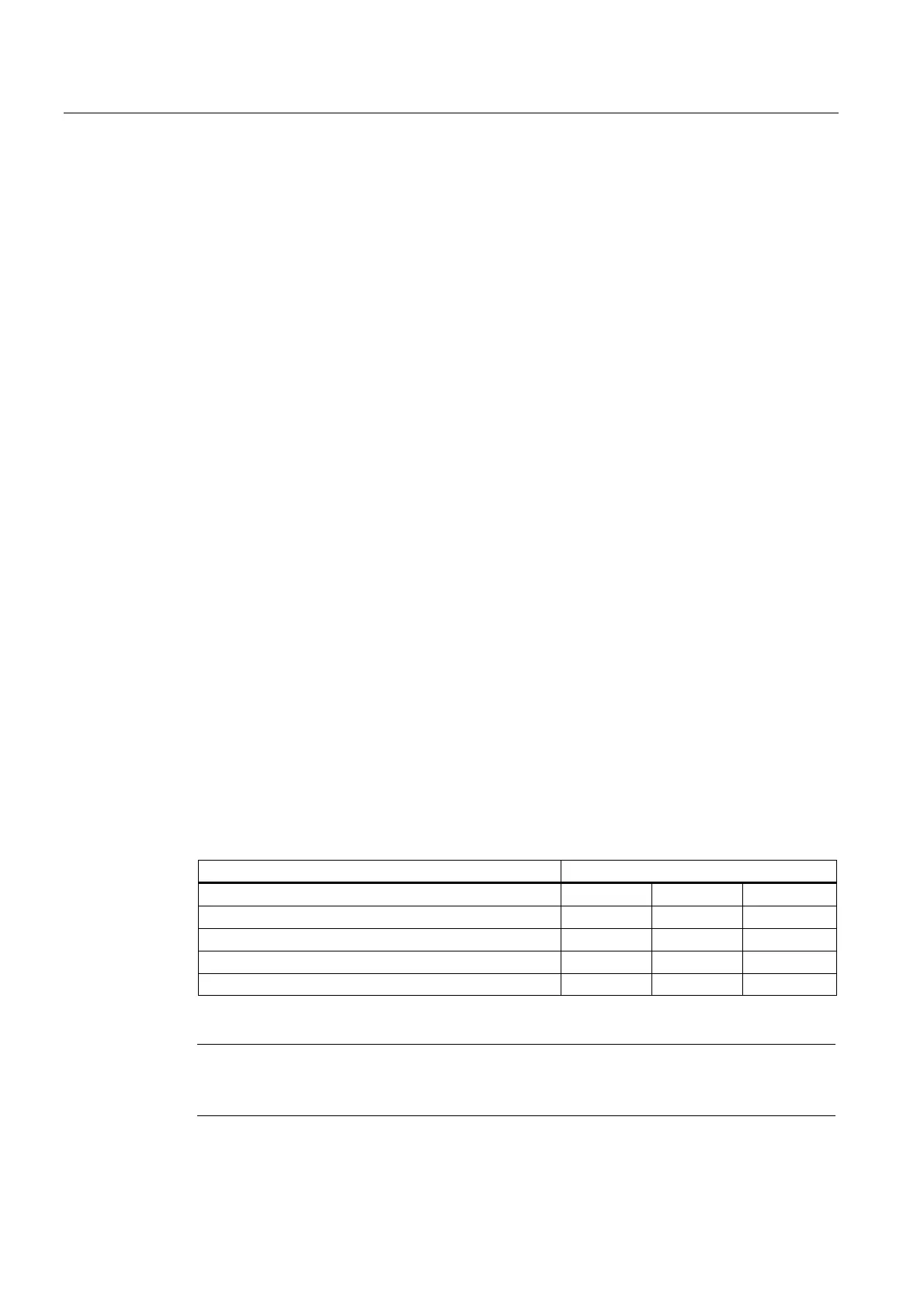

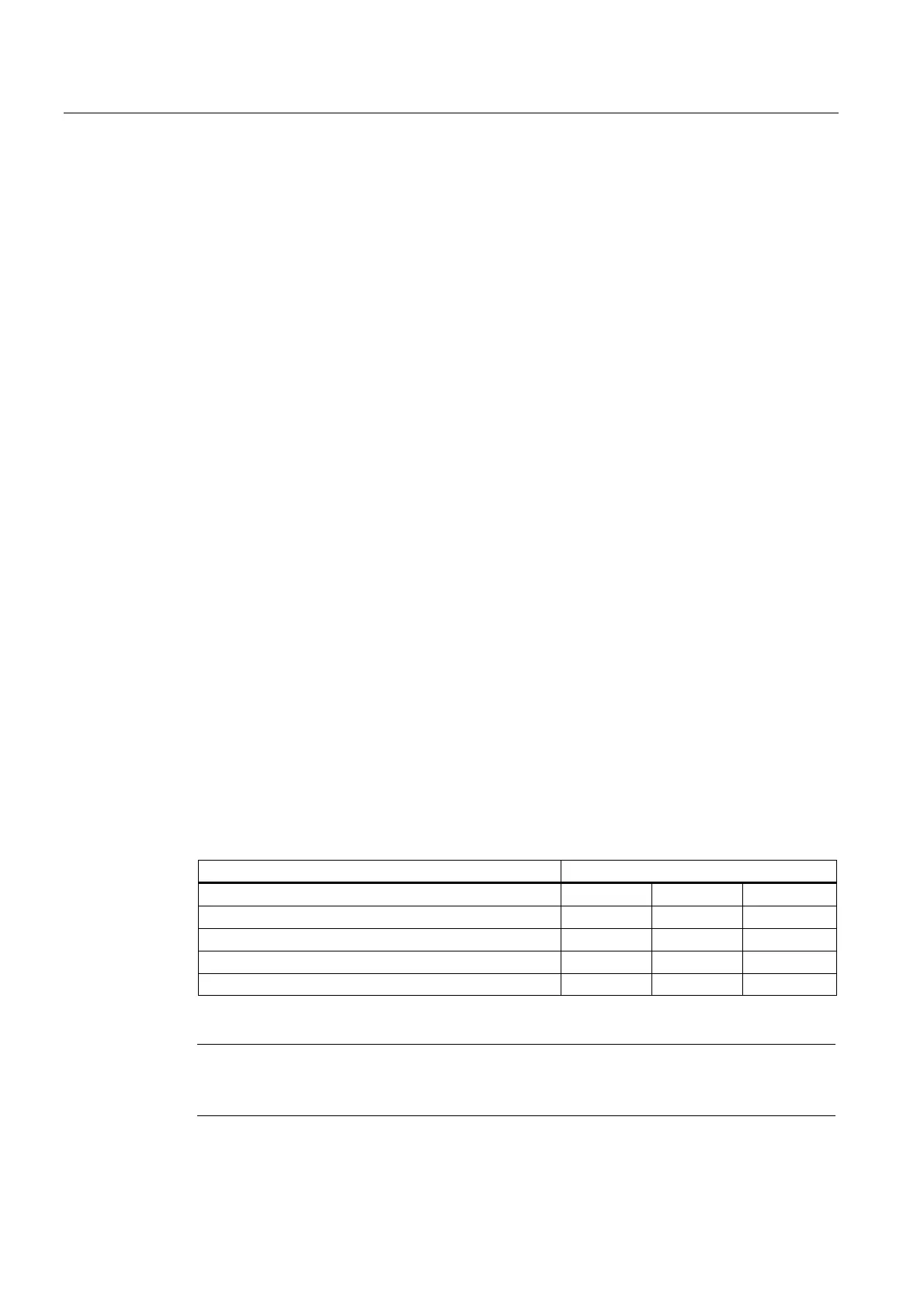

Setting Data Wear components

SD42910 $SC_MIRROW_TOOL_WEAR

TOWSTD TOWMCS TOWWCS

SD42920 $SC_WEAR_SIGN_CUTPOS X X —

SD42930 $SC_WEAR_SIGN X — —

SD42940 $SC_TOOL_LENGTH_CONST X X X

SD42950 $SC_TOOL_LENGTH_TYPE X X X

Note

Wear components, which are subjected to an active rotation by an adapter transformation or

a toolholder with orientation capability, are referred to as nontransformed wear components.

Loading...

Loading...