Detailed Description

2.8 Help function output to PLC (H2)

Basic logic functions: NC/PLC interface signals (Z1)

76 Function Manual, 11/2006, 6FC5397-0BP10-2BA0

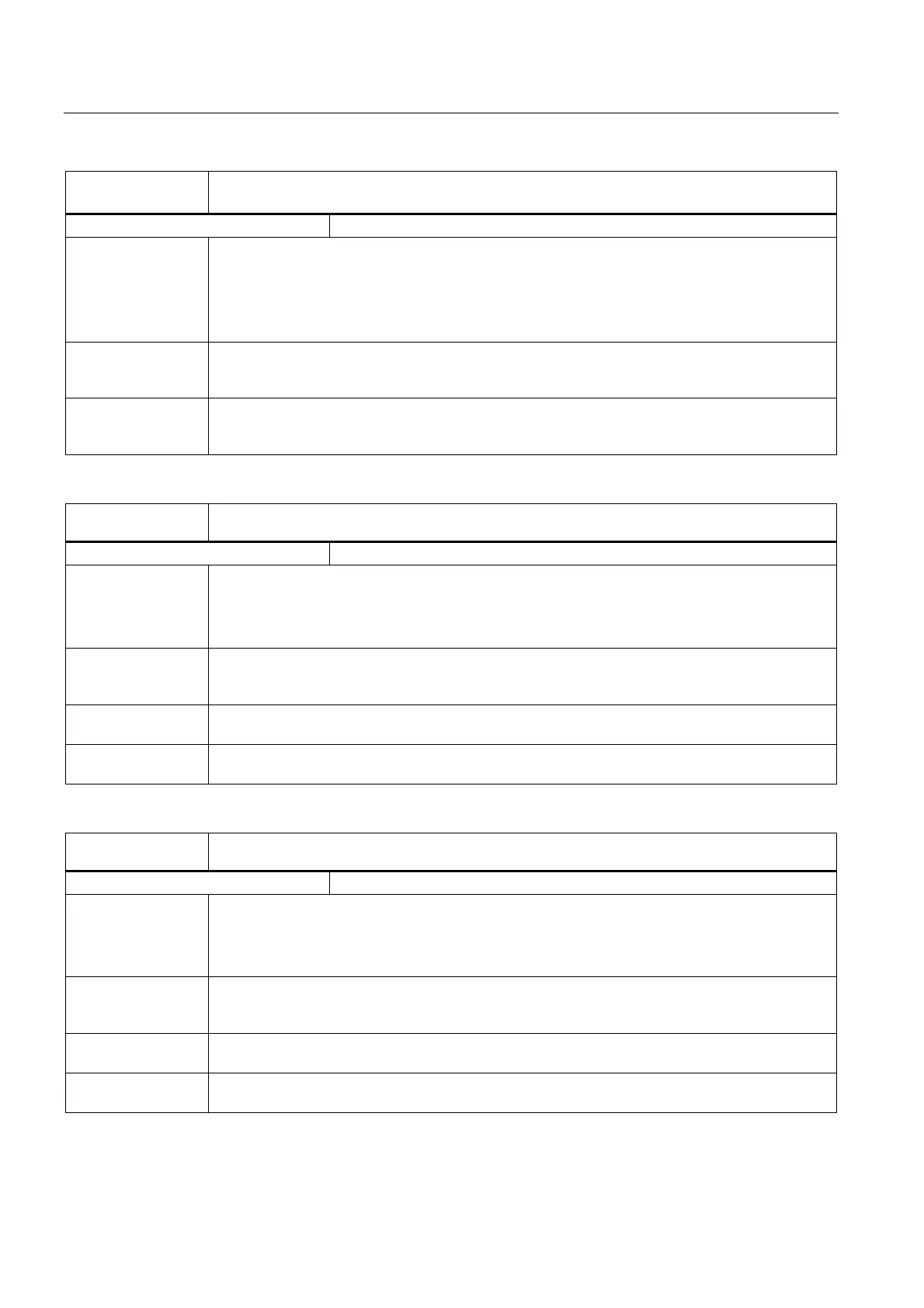

DB21, ...

DBB98 - DBB115

S functions 1 to 3

Extended address S functions 1 to 3

Edge evaluation: no Signal(s) updated: Jobcontrolled by NCK

Signal state 1 or

edge change

0 → 1

Up to 3 S functions programmed in an NC block are simultaneously made available here as soon

as the S change signals are available.

Value range of the spindle speed: 0 to 999 999; integer number

Value range of the extended address: 0 to 6; integer number

The S functions remain valid until they are overwritten by new S functions.

Signal state 0 or

edge change

1 → 0

• After the PLC has ramped-up.

• All help functions are deleted before a new function is entered.

Application

example(s)

Spindle speed control by the PLC.

The extended address is used to program for which spindle the S word is valid.

e.g.: S2=500

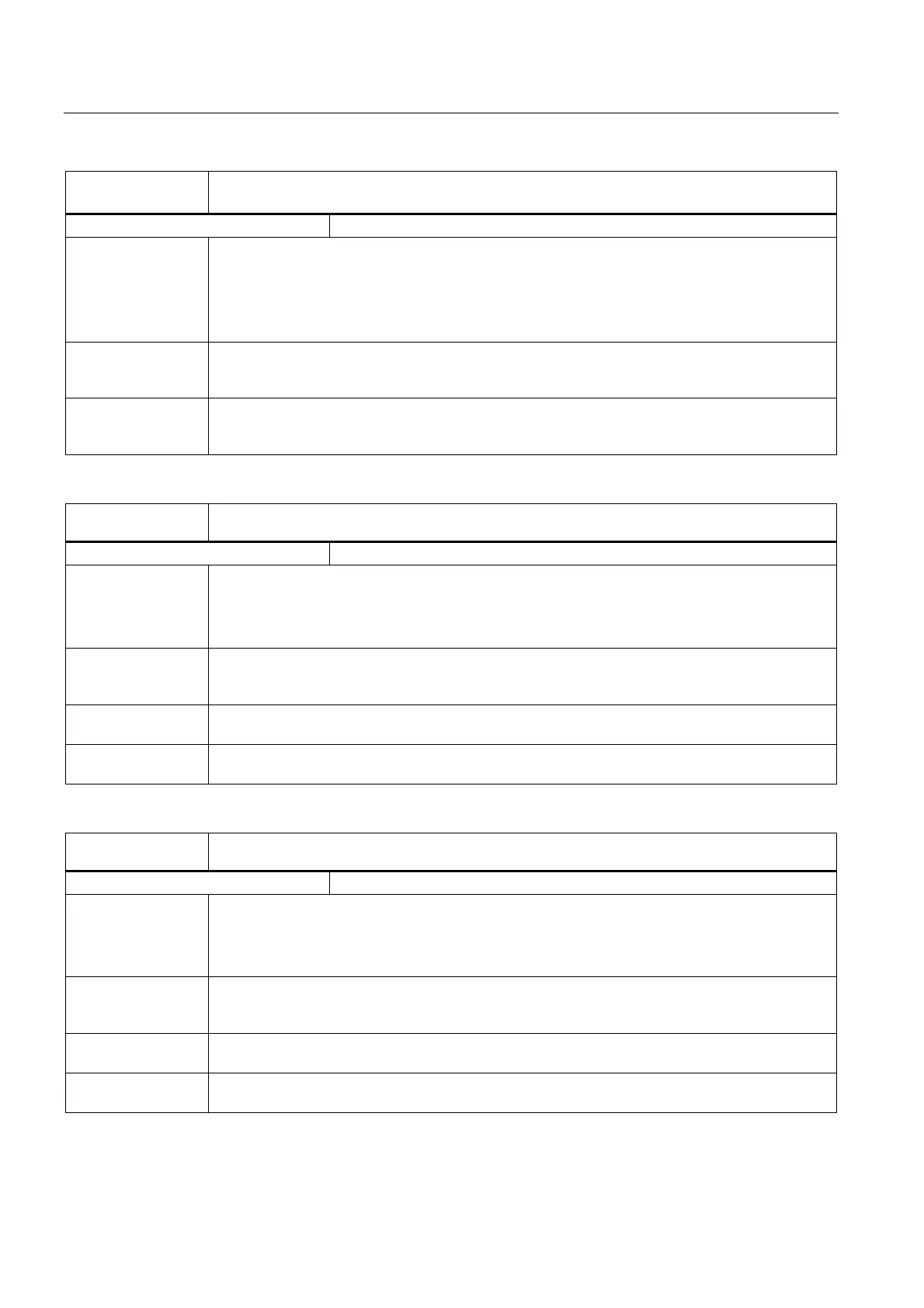

DB21, ...

DBB118, DBB119

T function 1

Edge evaluation: no Signal(s) updated: Jobcontrolled by NCK

Signal state 1 or

edge change

0 → 1

The T function programmed in an NC block is made available here

as soon as the T change signal is available.

Value range of T functions: 0 to 99 999 999; integer number

The T function remains valid until it is overwritten by a new T function.

Signal state 0 or

edge change

1 → 0

• After the PLC has ramped-up.

• All help functions are deleted before a new function is entered.

Application

example(s)

Control of automatic tool selection.

Special cases,

errors, ......

With T0, the current tool is removed from the tool holder but not replaced by a new tool (default

configuration of the machine manufacturer).

DB21, ...

DBB129

D function 1

Edge evaluation: no Signal(s) updated: Jobcontrolled by NCK

Signal state 1 or

edge change

0 → 1

The D function programmed in an NC block is made available here

as soon as the D change signal is available.

Value range of D functions: 0 to 999; integer number

The D function remains valid until it is overwritten by a new D function.

Signal state 0 or

edge change

1 → 0

• After the PLC has ramped-up.

• All help functions are deleted before a new function is entered.

Application

example(s)

Implementation of protective functions.

Special cases,

errors, ......

D0 is reserved for deselecting the current tool offset.

Loading...

Loading...