Detailed description

2.10 System settings for power-up, RESET/part-program end and part-program start

Basic logic functions: Mode group, channel, program operation, reset response (K1)

168 Function Manual, 11/2006, 6FC5397-0BP10-2BA0

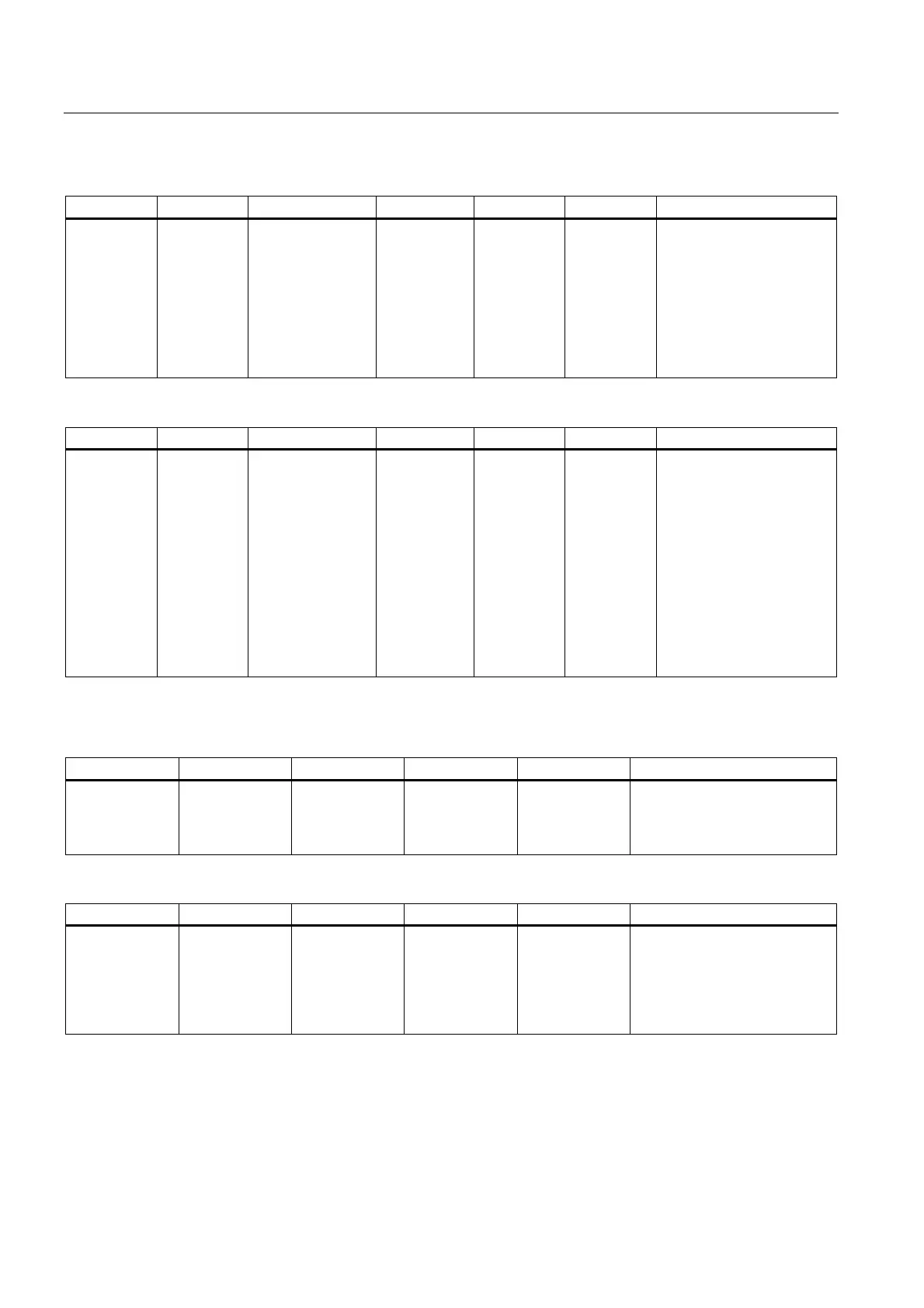

Table 2-14 Effect of MD20110 $MC_RESET_MODE_MASK Bits 0 to 6

Bit 0 = 1 Bit 1 = 1 Bit 2 = 1 Bit 3 = 1 Bit 4 = 1 Bit 5 = 1 Bit 6 = 1

Initial setting

after power

up and

RESET/end

of part

program

see above

No D, T, M

output on

tool

selection;

with active

tool

managemen

t irrelevant

If bit 0=1 and bit 6

=1, the tool offset

of the last active

tool is active after

POWER ON

(irrelevant with

active tool

management)

Use active

tool or tool

offset from

last test

program

terminated in

test mode

Current

plane is

retained, in

SW 5

replaced by

MD 20152

index 5

see below

Current

settable

frame is

retained, as

of SW 5

replaced by

MD 20152

index 7

see below

Active

tool offset is retained

Bit 0 = 0 Bit 1 = 0 Bit 2 = 0 Bit 3 = 0 Bit 4 = 0 Bit 5 = 0 Bit 6 = 0

Initial setting

after power

up and

RESET/end

of part

program

see above

D, T, M

output on

tool

selection;

with active

tool

managemen

t irrelevant

No tool offset

active after

POWER ON

(no effect when

tool management

active)

Use active

tool or tool

offset from

last program

terminated

before

program

testing

activated

Plane

according to

MD20150

$MC_GCOD

E_

RESET_

VALUES; in

SW 5 and

higher,

replaced by

MD 20152

index 5

see below

Frame

according to

MD20150

$MC_GCOD

E_

RESET_

VALUES; in

SW 5 and

higher,

replaced by

MD 20152

index 7

see below

WZK according to

MD20120

$MC_TOOL_RESET_VAL

UE, MD20121

$MC_TOOL_PRESEL_RE

SET_VALUE,

MD20130

$MC_CUTTING_

EDGE_RESET_VALUE;

Output of D, T, M to PLC,

depending on bit 1

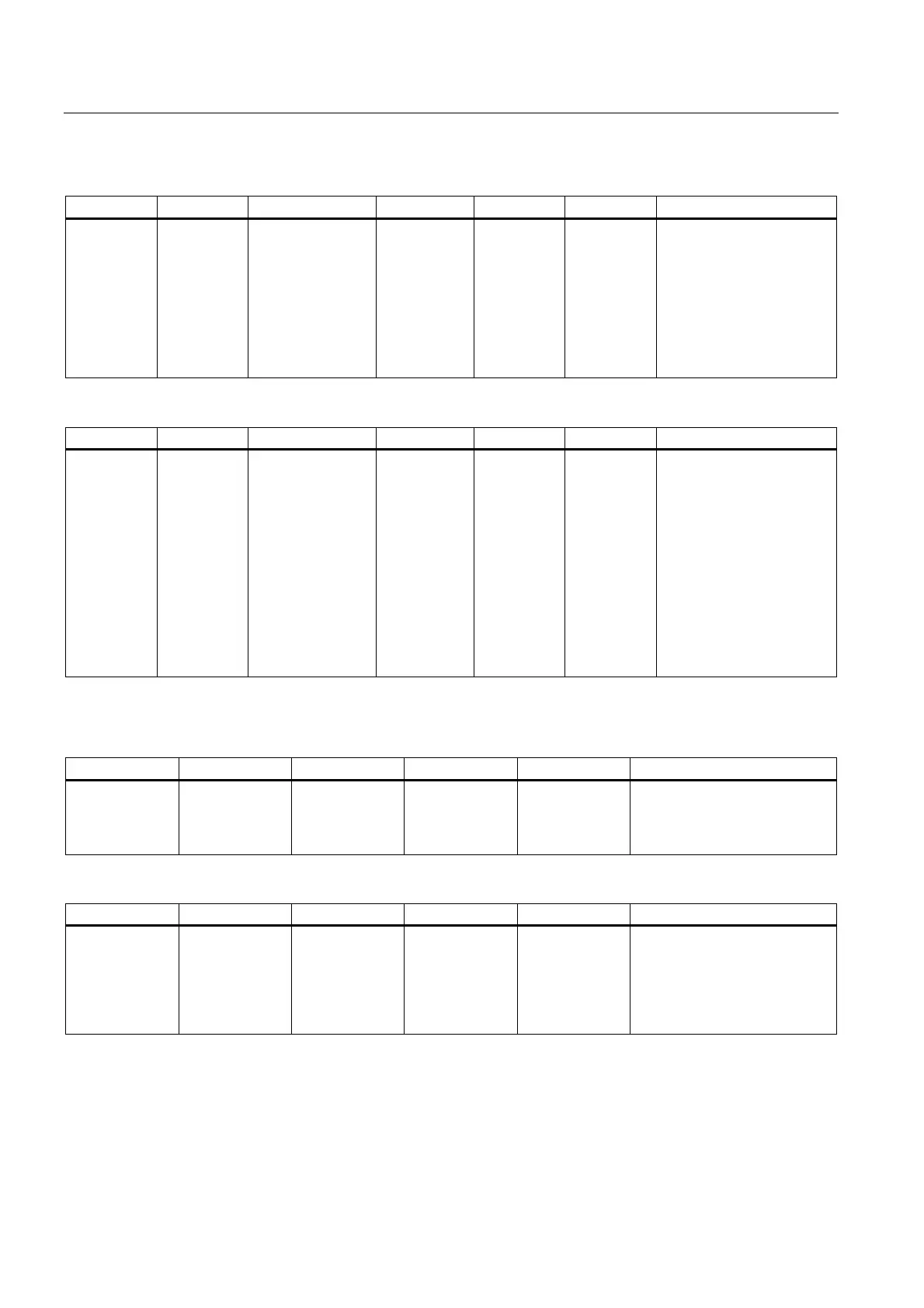

Table 2-15 Effect of MD20110 $MC_RESET_MODE_MASK Bits 7 to 12

Bit 7 = 1 Bit 8 = 1 Bit 9 = 1 Bit 10 = 1 Bit 11 = 1 Bit 12 = 1

Active

transformation

is retained

Coupledaxis

groupings are

retained

Tangential

follow-up is

retained

Not configured

synchronous

spindle coupling

remains active

Current setting

for revolutional

feedrate is

retained

Modified geometry axis

assignment is retained

Bit 7 = 0 Bit 8 = 0 Bit 9 = 0 Bit 10 = 0 Bit11 = 0 Bit 12 = 0

Transformation

according to

MD20140

$MC_TRAFO_R

ESET_VALUE

Coupledmotion

groupings are

deactivated

Tangential

follow-up is

deactivated

Not configured

synchronous

spindle coupling

is switched off

Revolutional

feedrate is no

longer valid

Modified geometry axis

assignment is deleted

according to

MD 20050, depending on

MD20118 (because of

compatibility)

Loading...

Loading...