RemovingandInstallingtheAuxiliaryHydraulicValveManifold(continued)

9.Operatetheauxiliaryvalve.Checkforhydraulicleaksandcorrectif

necessary.

10.Checkthehydraulicuidlevelandadjustifnecessarybeforereturningthe

machinetoservice.

ServicingtheAuxiliaryHydraulicValveManifold

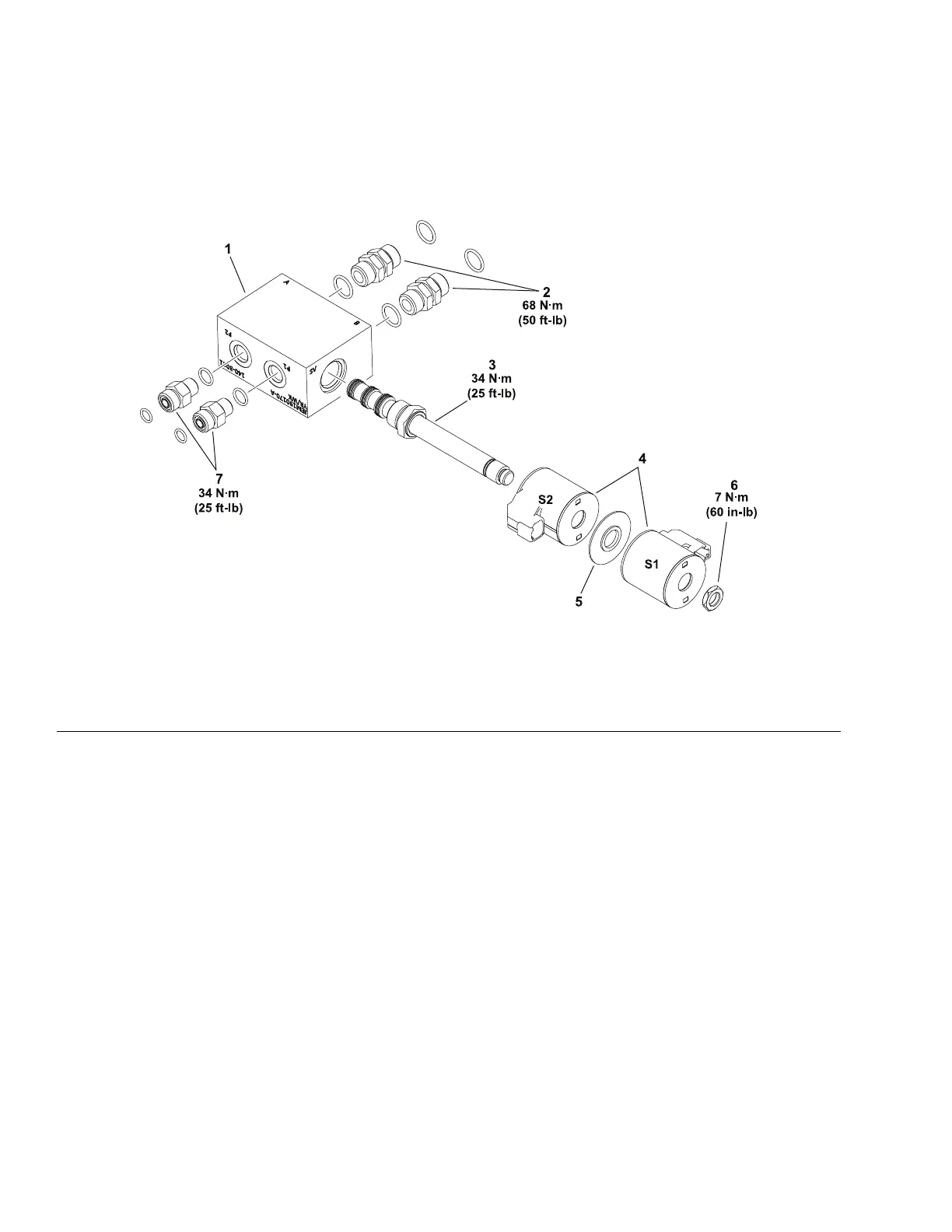

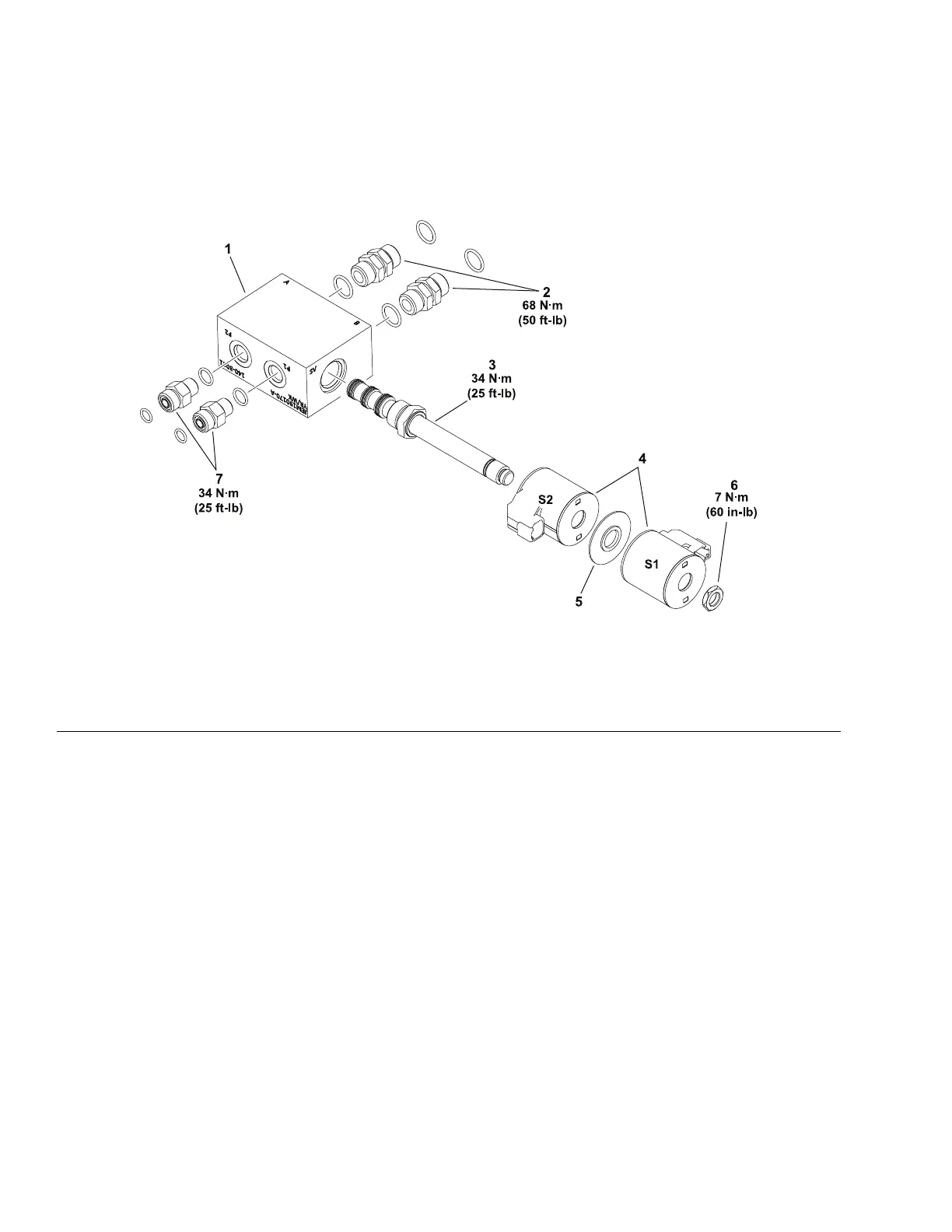

g303601

Figure73

1.Manifold4.Solenoidcoil(2each)7.Straighttting(2each)

2.Uniontting(2each)5.Coilspacer

3.Cartridgevalve6.Coilnut

Theportsonthemanifoldaremarkedforeasyidenticationofcomponents

andconnections;refertothehydraulicschematicinAppendixA(pageA–1)to

identifythefunctionofthecartridgevalveandhydrauliclinesateachport.

Forcartridgevalveserviceprocedures,refertoCartridgeValveService(page

5–93).

1.Markthettingorientationtoallowforcorrectassemblyandremovethe

quickdisconnectttings.

2.Removethemanifoldbracket.

3.Ifhydraulicttingsaretoberemovedfromthemanifold,markthetting

orientationtoallowforcorrectassembly.Removethettingsfromthe

manifoldanddiscardtheO−rings.

4.LubricatenewO-ringsandplacethemontothettings.Ifpreviouslyremoved,

installthettingsintothevalveports;refertoInstallingtheHydraulicFittings

(SAEStraightThreadO-RingFittings)(page5–9).

5.Installthemanifoldbracketandquickdisconnectttings.

HydraulicSystem:ServiceandRepairs

Page5–106

Groundsmaster

®

3200,3300and3310

19240SLRevA

Loading...

Loading...