5-33

CYLINDER AND PISTONS

EAS30293

CHECKING THE PISTON PINS

The following procedure applies to both of the

piston pins.

1. Check:

• Piston pin

Blue discoloration/grooves Replace the

piston pin and then check the lubrication sys-

tem.

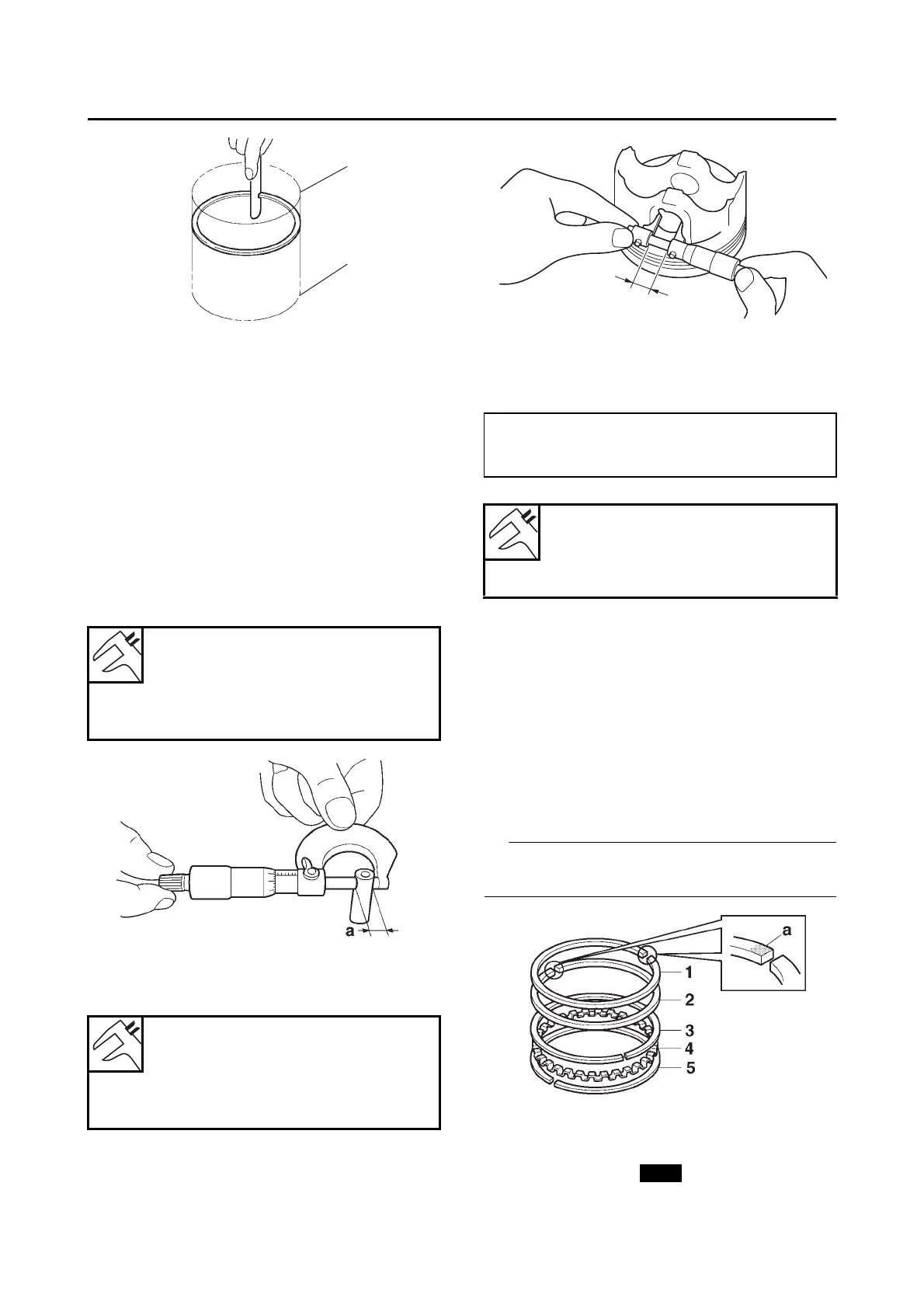

2. Measure:

• Piston pin outside diameter “a”

Out of specification Replace the piston pin.

3. Measure:

• Piston pin bore inside diameter “b”

Out of specification Replace the piston.

4. Calculate:

• Piston-pin-to-piston-pin-bore clearance

Out of specification Replace the piston pin

and piston as a set.

EAS30294

INSTALLING THE PISTON AND CYLINDER

The following procedure applies to all of the pis-

tons and cylinders.

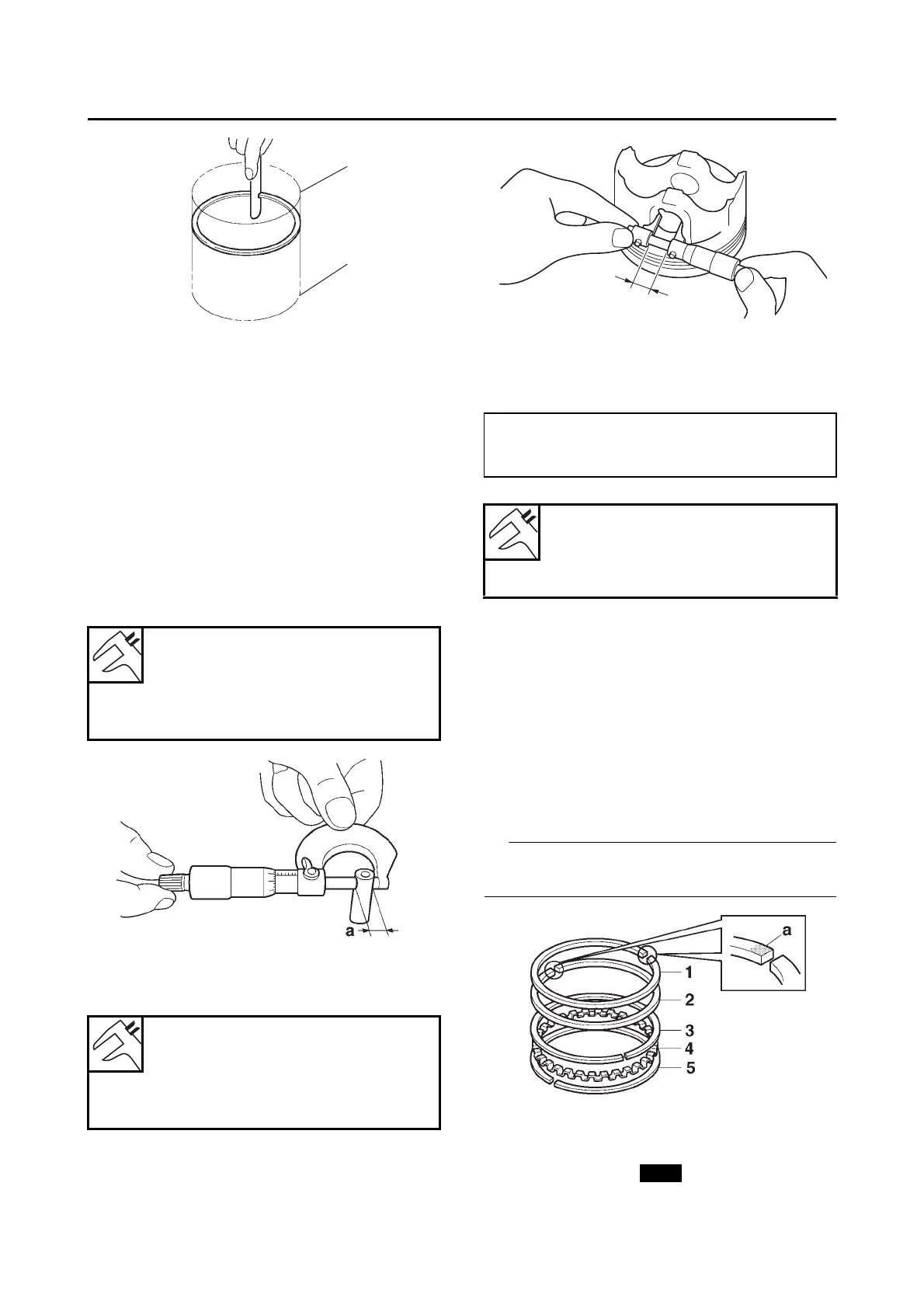

1. Install:

• Oil ring expander “1”

• Lower oil ring rail “2”

• Upper oil ring rail “3”

• 2nd ring “4”

• Top ring “5”

(into the piston)

Be sure to install the top and 2nd rings so that

the manufacturer marks or numbers “a” face up.

2. Install:

• Piston “1”

• Piston pin “2”

• Piston pin clip “3”

a. Bottom of cylinder

b. Upper of cylinder

Piston pin outside diameter

16.995–17.000 mm

(0.6691–0.6693 in)

Limit

16.975 mm (0.6683 in)

Piston pin bore inside diameter

17.002–17.013 mm

(0.6694–0.6698 in)

Limit

17.043 mm (0.6710 in)

Piston-pin-to-piston-pin-bore clearance =

Piston pin bore inside diameter -

Piston pin outside diameter

Piston-pin-to-piston-pin-bore

clearance

0.002–0.018 mm (0.0001–0.0007

in)

Loading...

Loading...