<Appendix 5. PID Block>

285

IM 01E21A02-03EN

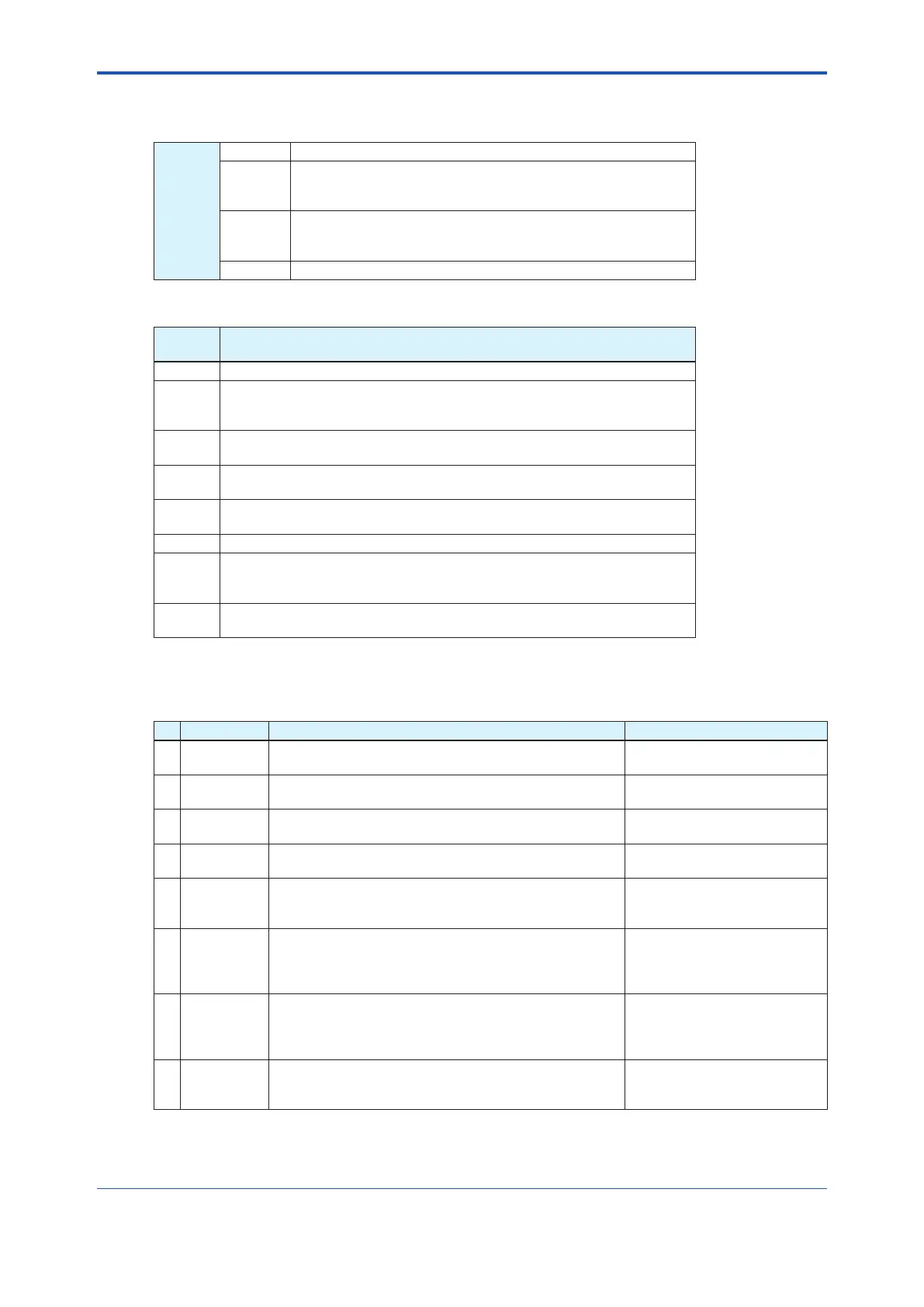

A5.9 Block Modes

TheblockmodeisdenedwiththeparameterMODE_BLK.

MODE_

BLK

Target Denesthetargetmode.

Actual

Indicates the current block mode.

Changes depending on the status of input data and target

contents.

Permitted

Denesconstraintsofthetargetmode.

Ifconstraintsarenotdenedhere,itbecomesimpossibleto

transition to the mode.

Normal Denesthenormalmode.

There are eight modes for the PID block as shown below.

Block

Mode

Description

ROut Remote output mode. The mode outputs the value given by ROUT_IN.

RCas

Bytheremotecascadeconnection,thesetpoint(SP)isreceivedfromthe

host computer, etc., and results of the PID control calculation processing are

output.

Cas

Bythecascadeconnection,thesetpoint(SP)isreceivedfromotherfunction

block, and results of the PID control calculation processing are output.

Auto

The PID block carries out automatic control and outputs the result calculated

by the PID control computation.

Man

The block goes into manual mode, and outputs OUT, the value set by the user

manually.

LO ThePIDblockoutputstheoperationoutputvaluesetinTRK_VAL.

IMan

Initialization and manual mode. This mode temporarily interrupts the control

operation. The mode which operates when the initialization and manual

fallback conditions shown in Section A5.14 are met.

O/S

Control calculation processing is carried out. The output of the previous value

is kept.

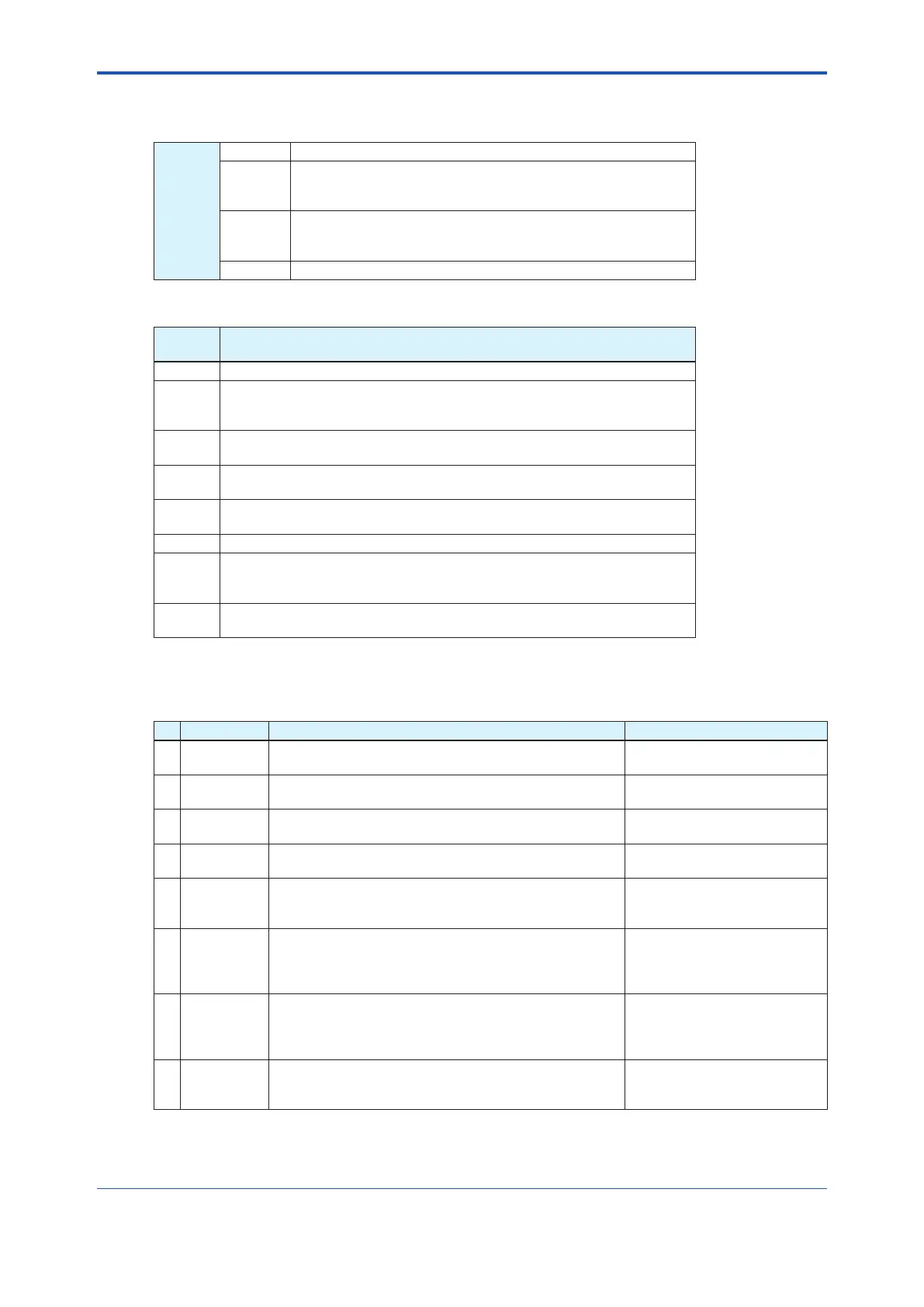

A5.9.1 Mode Transitions

Destination Condition Other Condition

(1) O/S

IfO/SisspeciedinMODE_BLK.target

(orifO/Sissetintargetinsidetheresourceblock)

(2) IMan

If the Initialization and manual fallback conditions are met

(SectionA5.14)

NOTifcondition(1)ismet

(3) LO

IfTrackEnableisspeciedinCONTROL_OPTSandthe

valueofTRK_IN_Distrue

NOT if either or both of

conditions(1)and(2)aremet

(4) Man

IfMANisspeciedinMODE_BLK.targetorifIN.status

(inputstatus)isBAD

NOT if any one or more of

conditions(1)to(3)aremet

(5) Auto

IfAutoisspeciedinMODE_BLK.target

- AND -

ifIN.status(inputstatus)isotherthanBAD

NOT if any one or more of

conditions(1)to(3)aremet

(6) Cas

IfCasisspeciedinMODE_BLK.target

- AND -

ifIN.Status(inputstatus)andCAS_IN.Statusareother

than BAD

NOT if any one or more of

conditions(1)to(3)aremet

(7) RCas

IfRCasisspeciedinMODE_BLK.target

- AND -

ifIN.Status(inputstatus)andRCAS_IN.Statusareother

than BAD

NOT if any one or more of

conditions(1)to(3)aremet

(8) ROut

IfROutisspeciedinMODE_BLK.target

- AND -

ifROUT_IN.status(inputstatus)isotherthanBAD

NOT if any one or more of

conditions(1)to(3)aremet

Note 1: To activate mode transitions to Auto, Cas, RCas, and ROut, the respective target modes

mustbepermittedbeforehandwithMODE_BLK.permitted.

Loading...

Loading...