250 Rockwell Automation Publication 193-UM015E-EN-P - October 2015

Chapter 5 Operating Modes

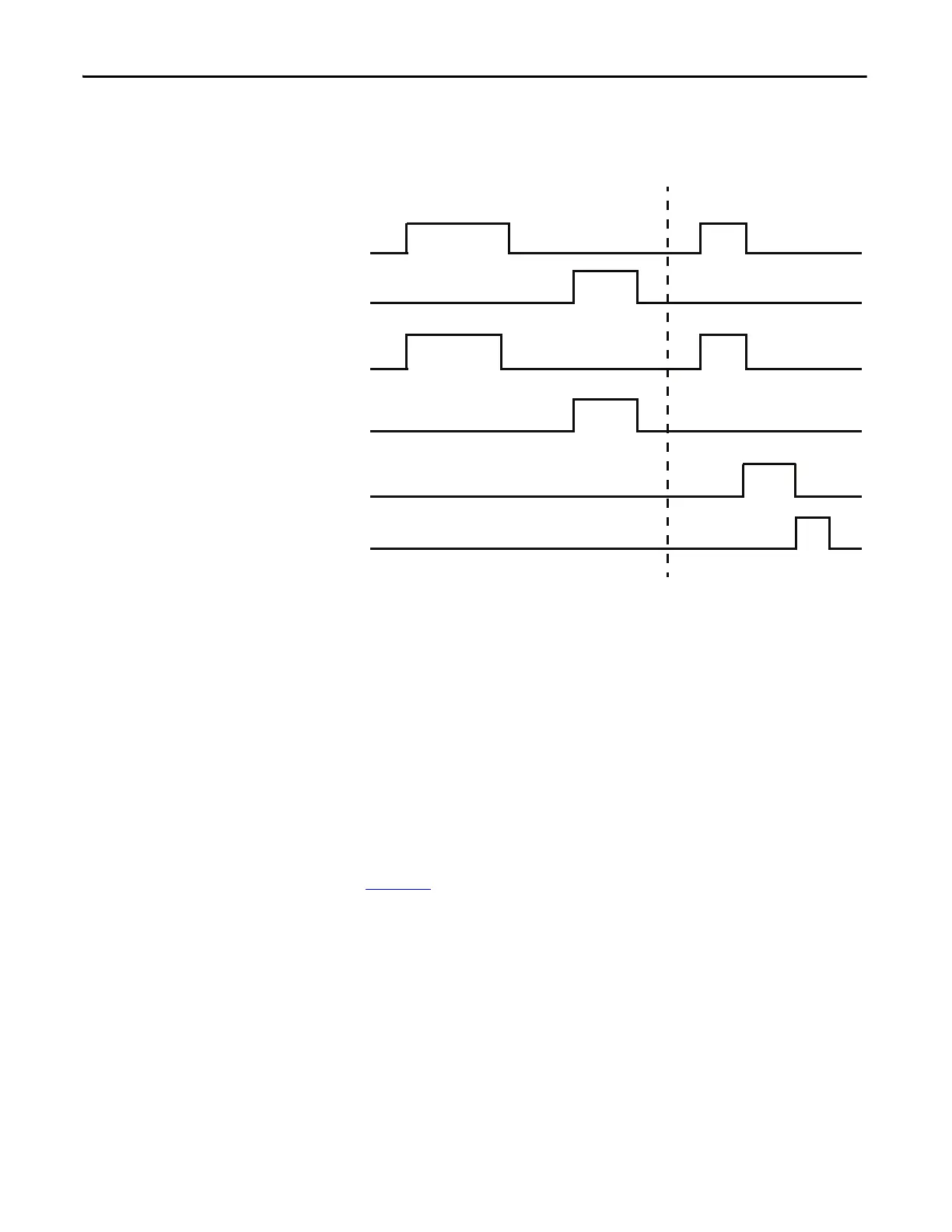

Timing Diagram

Figure 154 - Reversing Starter (Network & Local I/O) – Two-wire Control Timing Diagram

Reversing Starter (Network & Local I/O) – Three-wire Control

The E300 relay’s Operating Mode Reversing Starter (Network& Operator Station)

(Parameter 195 = 21) in Remote control mode uses network tags

LogicDefinedPt00Data in Output Assembly 144 to control Relay 0, which

controls the forward contactor coil, and LogicDefinedPt01Data in Output

Assembly 144 to control Relay 1, which controls the reversing contactor coil.

Both LogicDefinedPt00Data and LogicDefinedPt01Data are maintained values,

so the reversing starter remains energized when LogicDefinedPt00Data or

LogicDefinedPt01Data has a value of 1. You can program the appropriate state of

the starter when communication is lost using the Network Communication Fault

and Network Communication Idle parameters (Parameters 569 – 573) described

in Chapter 4

.

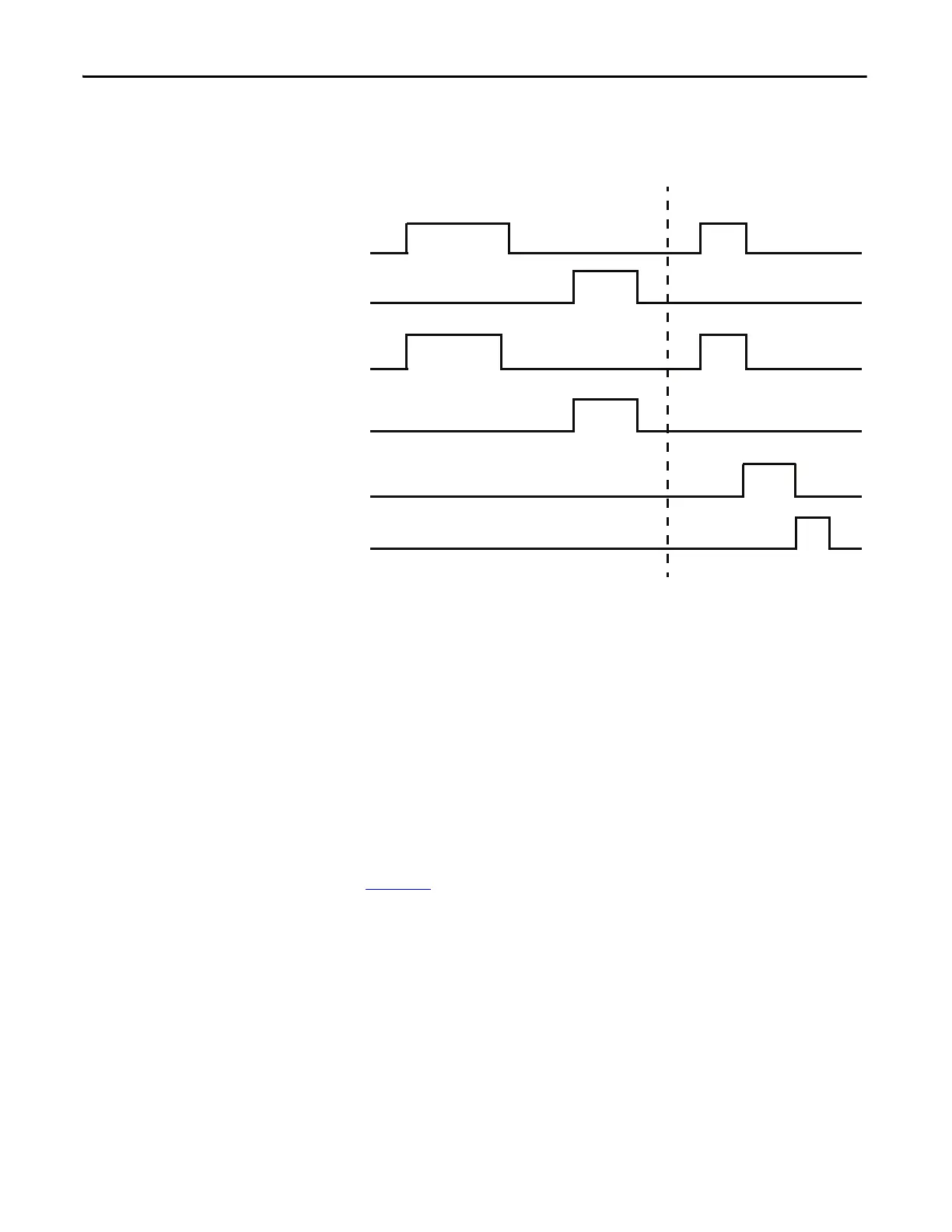

Local control mode uses a normally open momentary push button in Input 0 to

energize Output Relay 0, which controls the forward contactor coil. A normally

open momentary push button in Input 1 is used to energize Output Relay 1,

which controls the reversing contactor coil. A normally closed push button in

Input 2 is used to de-energize Output Relay 0 and Output Relay 1. Both Input 0,

Input 1, and Input 2 are momentary signals, so the reversing starter only energizes

if Input 2 is active and Input 0 or Input 1 is momentarily active.

Input 2 must be momentarily de-active before changing to another direction.

Trip Event

REV (Relay 1)

FWD (Relay 0)

Trip Status

Trip Reset

Forward

Reverse

Loading...

Loading...