DL205 Analog Manual, 7th Edition Rev. D

14-13

Chapter 14: F2-4AD2DA 4-Ch. In / 2-Ch. Out Analog Combination

1

2

3

4

5

6

7

8

9

10

11

12

13

14

A

B

C

D

1

2

3

4

5

6

7

8

9

10

11

12

13

14

A

b

C

D

Writing the Control Program

Before starting to write the program, some supplemental examples can be very helpful to the

programmer, such as:

• Input power failure detection

• Output data calculation

• Input data scaling

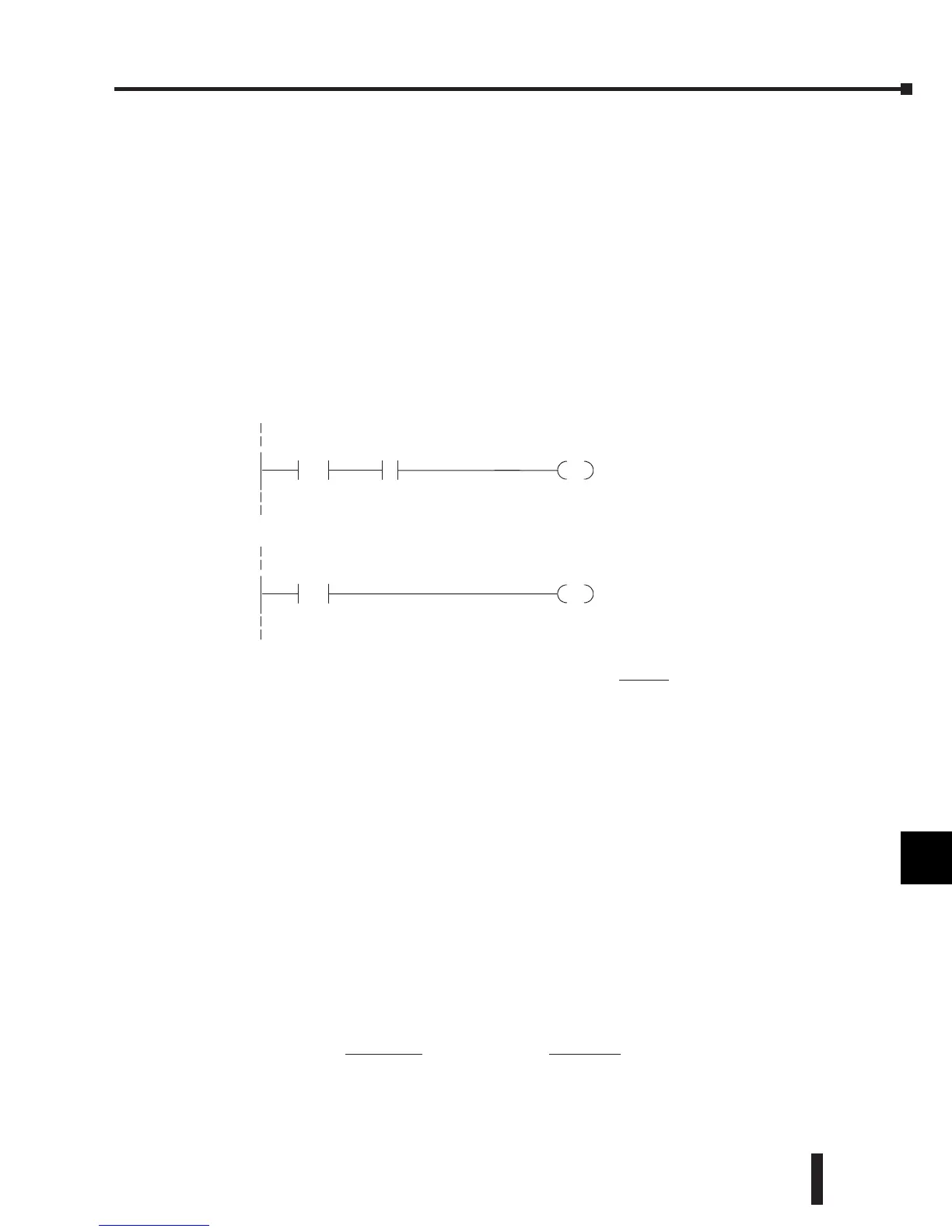

Analog Input Failure Detection

The analog module has a microcontroller that can diagnose analog input circuit problems.

Ladder logic can be written to detect these problems. The following rung shows an input

point that would be assigned if the module was used as shown in the previous and following

examples.

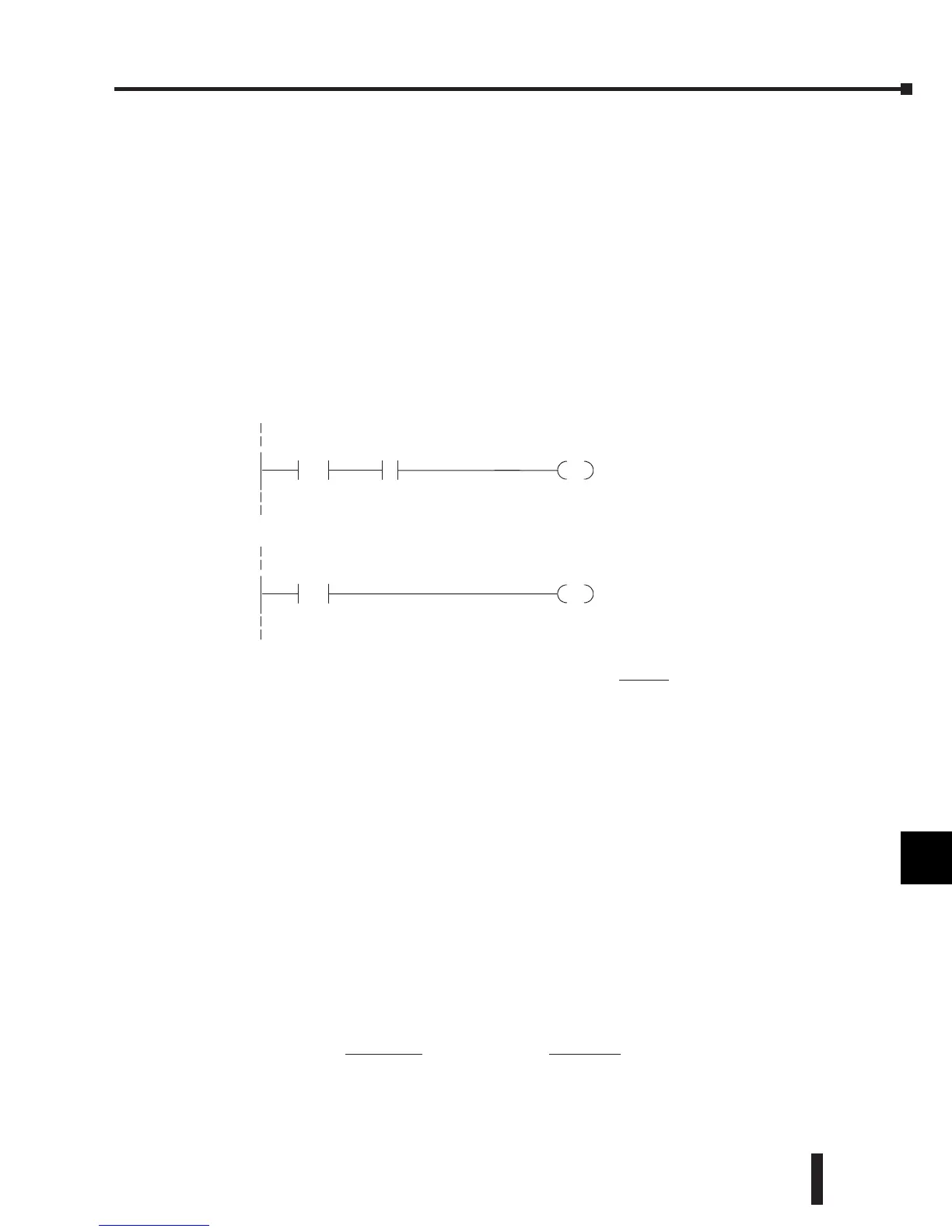

Calculating the Digital Value

The control program must calculate

the digital value that is sent to the

analog output. Several methods can be

used to do this, but the best method

is to convert the values to engineering

units. This is accomplished by using

the formula shown.

Adjustments may need to be made to

the formula depending on the scale of

the engineering units.

Consider the following example which controls pressure from 0.0–99.9 PSI. Using the

formula will calculate the digital value to be sent to the analog output. The example shows

the conversion required to yield 49.4 PSI. The multiplier of 10 is used because the decimal

portion of 49.4 cannot be loaded in the program, so it is shifted right one decimal place to

make a usable value of 494.

A = U

4095

H–L

A = Analog Value (0–4095)

U = Engineering Units

H = High limit of the engineering

unit range

L = Low limit of the engineering

unit range

V2000 K0

=

V-memory locationV2000 holds

channel1data.When a datavalue

of zero is returned and inputX37 is

on,thenthe analog channel is not

operating properly.

X37

OUT

C1

Loading...

Loading...