DL205 Analog Manual, 7th Edition Rev. D

2-17

Chapter 2: F2-04AD-1, F2-04AD-1L, 4-Channel Analog Current Input

1

2

3

4

5

6

7

8

9

10

11

12

13

14

A

B

C

D

1

2

3

4

5

6

7

8

9

10

11

12

13

14

A

b

C

D

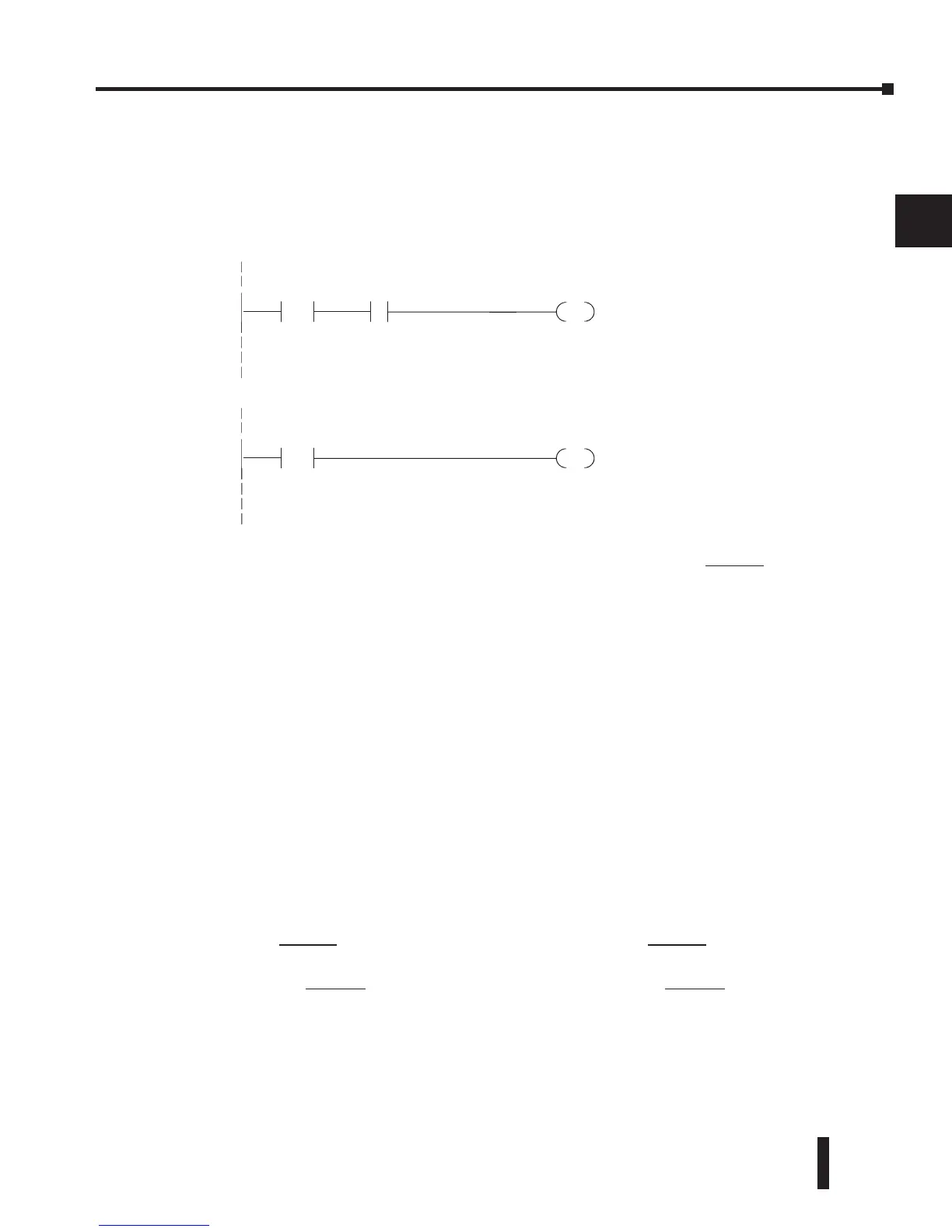

Analog Power Failure Detection

The Analog module has an on-board processor that can diagnose analog input circuit

problems. A ladder rung can be edited to detect these problems. This rung shows an input

point that would be assigned if the module was installed as shown in the previous examples.

A different point would be used if the module was installed in a different I/O arrangement.

Scaling the Input Data

Most applications usually require

measurements in engineering units which

provides more meaningful data. This is

accomplished by using the conversion formula

shown.

Adjustments may be needed to the formula

depending on the scale being used for the

engineering units.

For example, if pressure (PSI) is to be

measured from 0.0 – 99.9 then multiply the value by 10 in order to imply a decimal place

when viewing the value with the programming software or with a handheld programmer.

Notice how the calculations differ when the multiplier is used.

V2000 K0

=

X37

OUT

C1

V-memory locationV2000 holds

channel 1 data. Whenadatavalue

of zero is returned and inputX37 is

on, then theanalog circuitryisnot

operatingproperly.

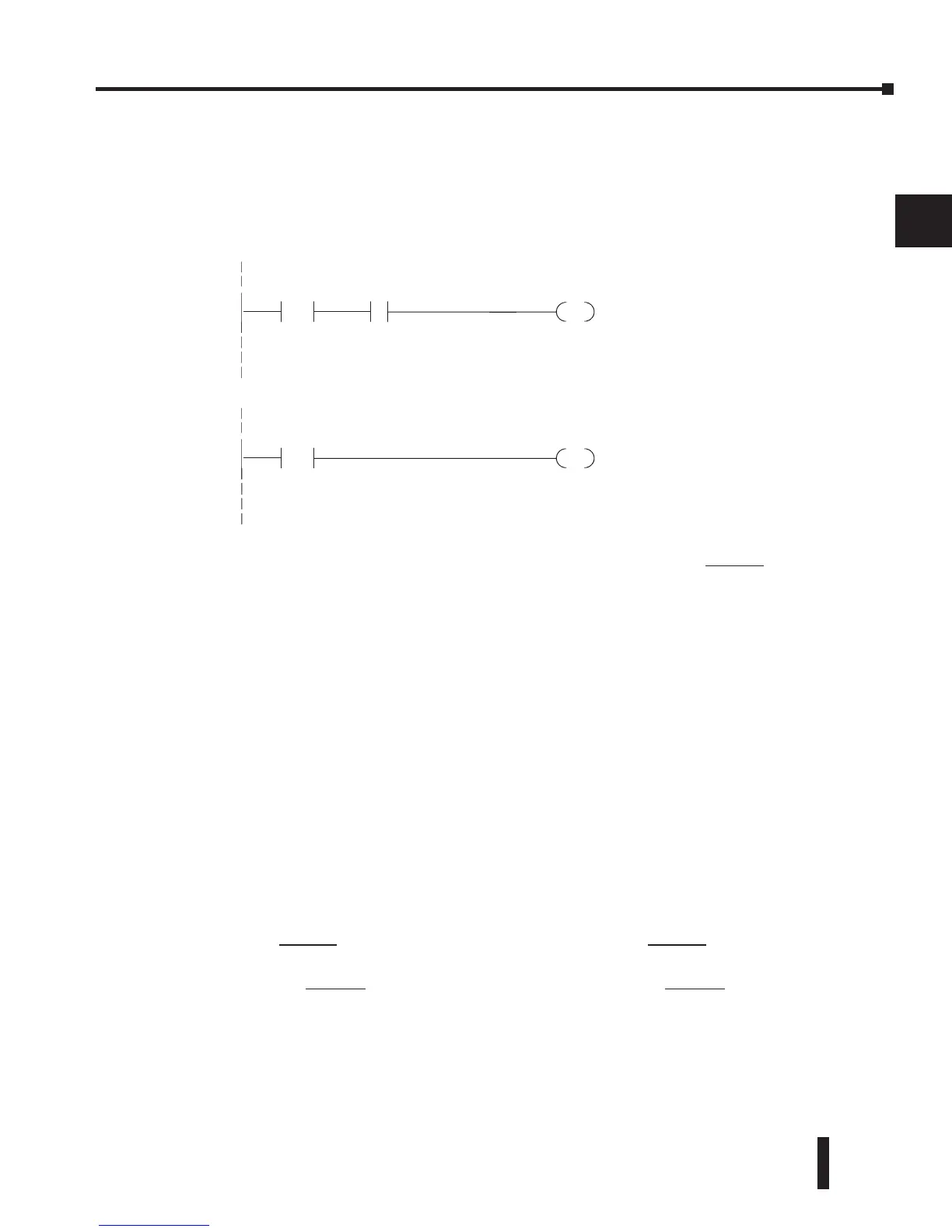

V2000 K8000

=

OUT

C1

Pointer method

V-memory locationV2000 holds

channel1data.When a datavalue

of 8000 is returned,then the analog

circuitry is not operatingproperly.

Units = A

H – L

4095

U = Engineering Units

A = Analog Value (0 – 4095)

H = High limit of the engineering

unit range

L = Low limit of the engineering

unit range

Units = A

H – L

4095

Units = 2024

100 – 0

4095

Units = 49

Units = 10A

H – L

4095

Units = 20240

100 – 0

4095

Units = 494

Analog Value of 2024, slightly less than half scale, should yield 49.4 PSI.

Example without multiplier Example with multiplier

Loading...

Loading...