2000X energy Power Supply Appendix D Automation

Instruction Manual FAQ: 2000 SERIES AUTOMATION

011-003-991 EN D-5

A. 2000 Series products use identical air cylinder sizes as prior models, therefore the air consumption tables

from prior series documentation will still apply.

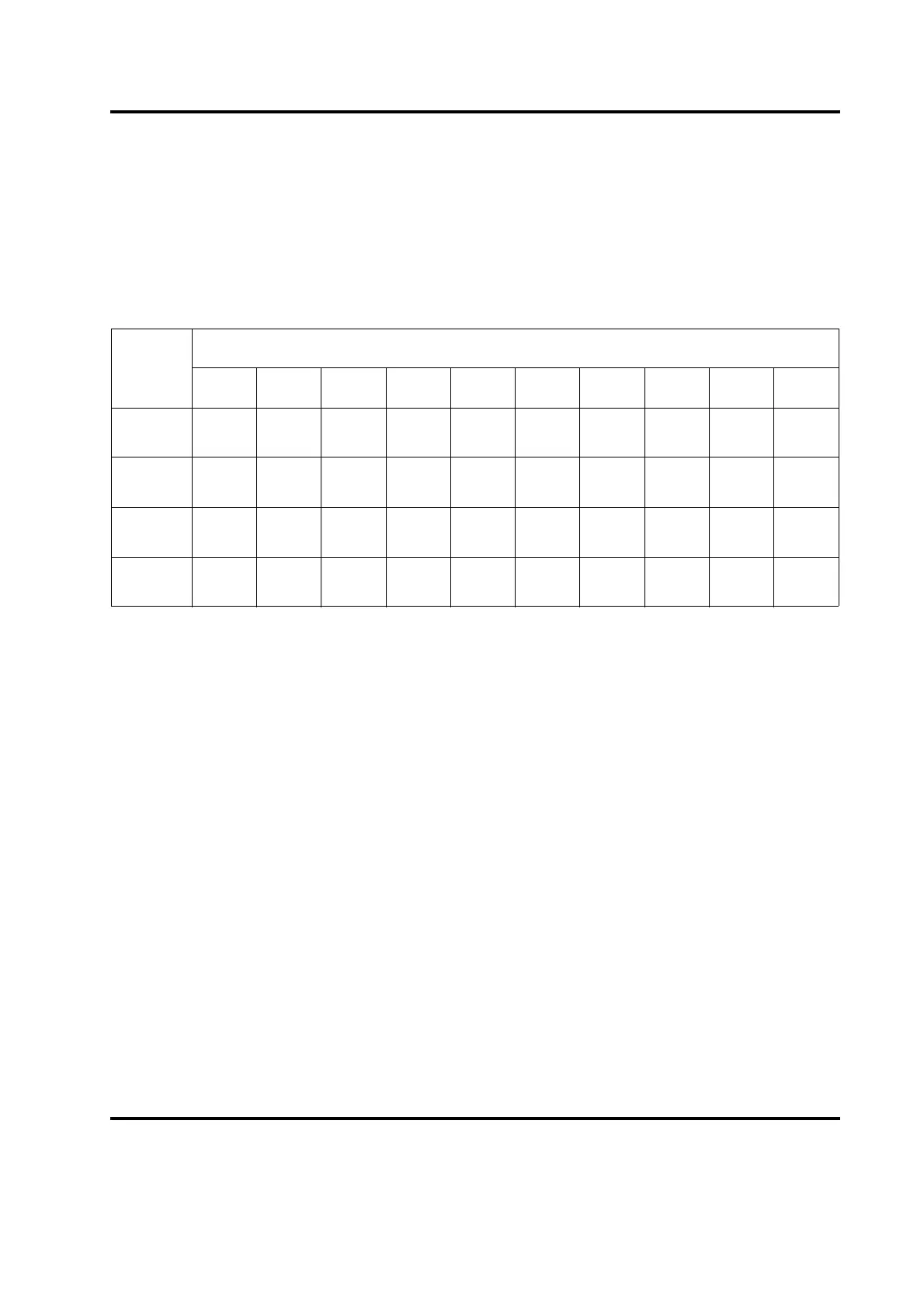

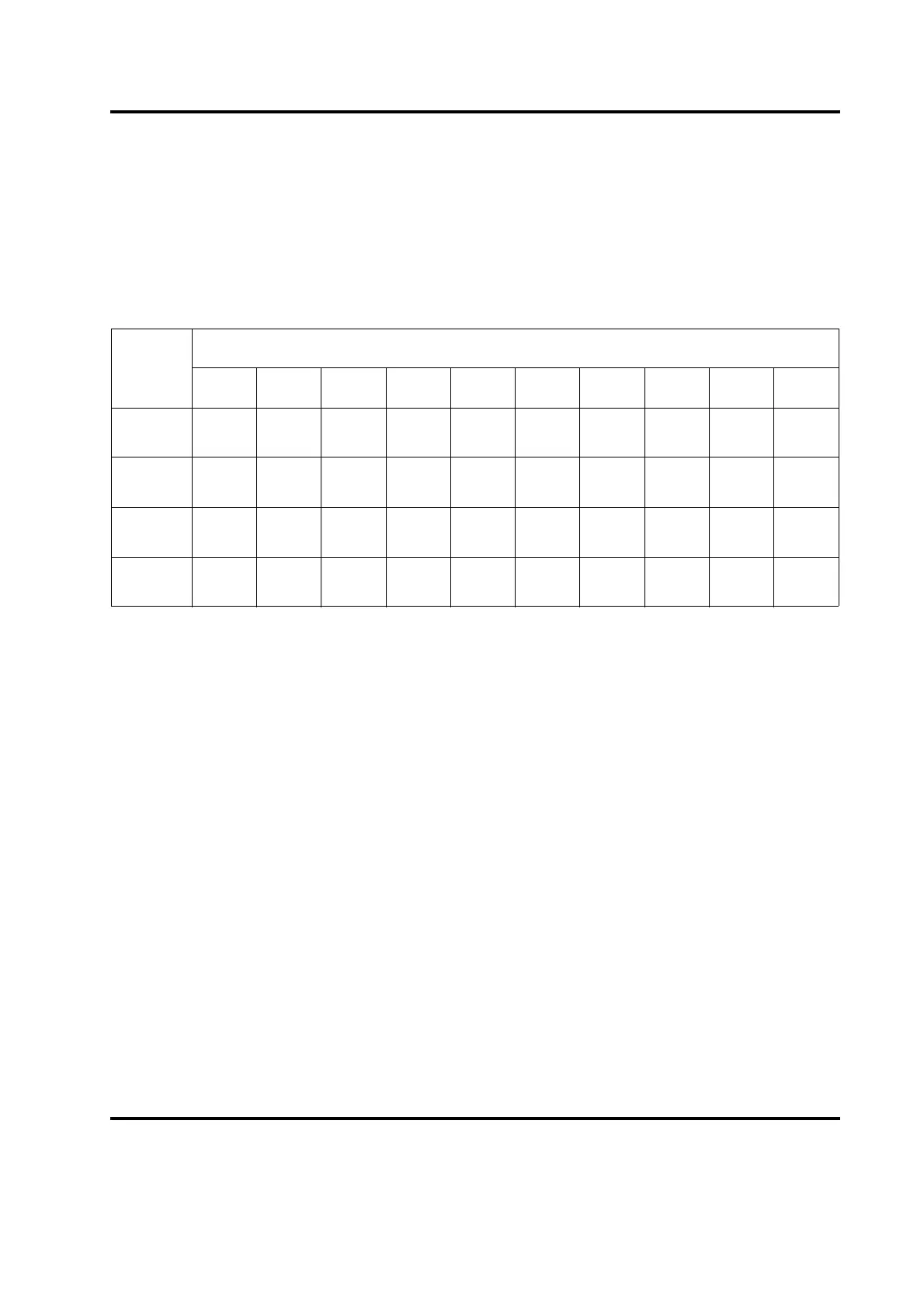

Table D.1 Air Consumption

Cubic Feet of air per Minute per inch of stroke length (each direction)

Use the above table to calculate the air used by the air cylinder.

Add 0.034 Cubic foot per Second of actual weld time to account for converter cooling air per weld cycle. (2

CFM)

For example:

3.0 inch aed actuator running at full pressure (100psi) and stroke length (4inches) at a cycle rate of 20 parts

per minute = 0.0319 CFM per inch of stroke(from above table) X 8 inches (total stroke is 4 inches down and

4 inches back) equals 0.2552 CFM per stroke. Weld time is 1 second so: 0.034 X 1 equals 0.034 CFM for

cooling.

Adding 0.2552 CFM for the cylinder and 0.034 CFM for cooling equals 0.2892 CFM per cycle. Multiply for

parts per minute (20) and you get a total of 5.784 CFM.

This would very likely be a worst-case condition any welder could run at.

However we have a slightly different condition for an 2000f/aef welding system. Because the pneumatics

are used as differential mode of operation, we would suggest to always use the 100 psi values from the

above table to be on the conservative side for sizing airflow, rather than on the actual force values. Still add

the same converter cooling values (0.034) as in the prior example.

Cylinde

r Size

Air Pressure (PSI)

10 20 30 40 50 60 70 80 90 100

1.5

0.001

74

0.002

43

0.003

12

0.003

81

0.004

50

0.005

13

0.005

90

0.006

60

0.007

30

0.008

00

2

0.003

17

0.004

37

0.005

57

0.006

77

0.008

00

0.009

30

0.010

40

0.011

70

0.013

00

0.014

20

2.5

0.004

90

0.006

80

0.008

70

0.010

60

0.012

50

0.014

40

0.016

30

0.018

30

0.020

40

0.022

30

3

0.006

80

0.009

60

0.012

40

0.015

20

0.018

00

0.020

80

0.023

50

0.026

70

0.029

10

0.031

90

Loading...

Loading...