2000X energy Power Supply Chapter 4: Installation and Setup

Instruction Manual Guards and Safety Equipment

011-003-991 EN 4-35

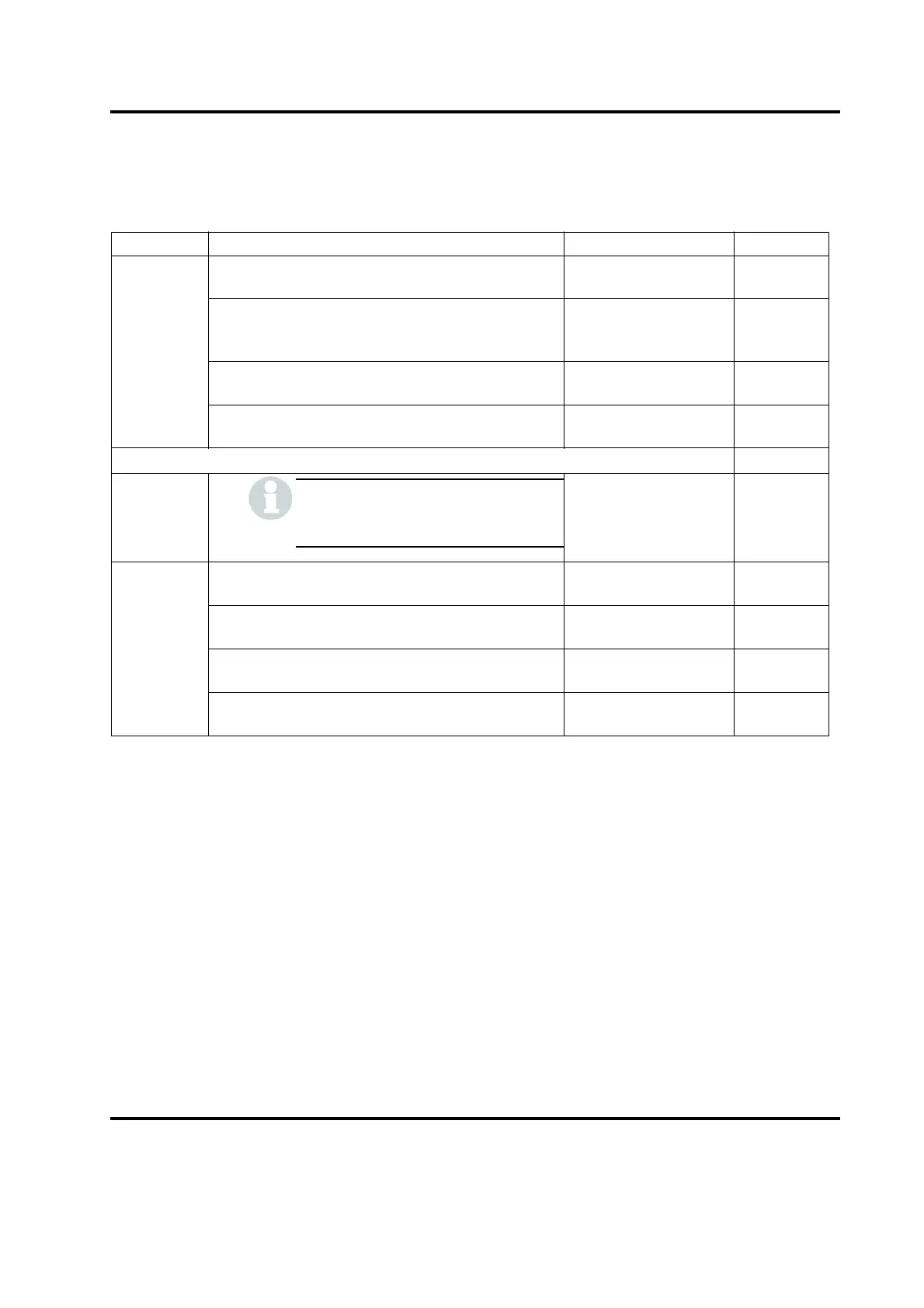

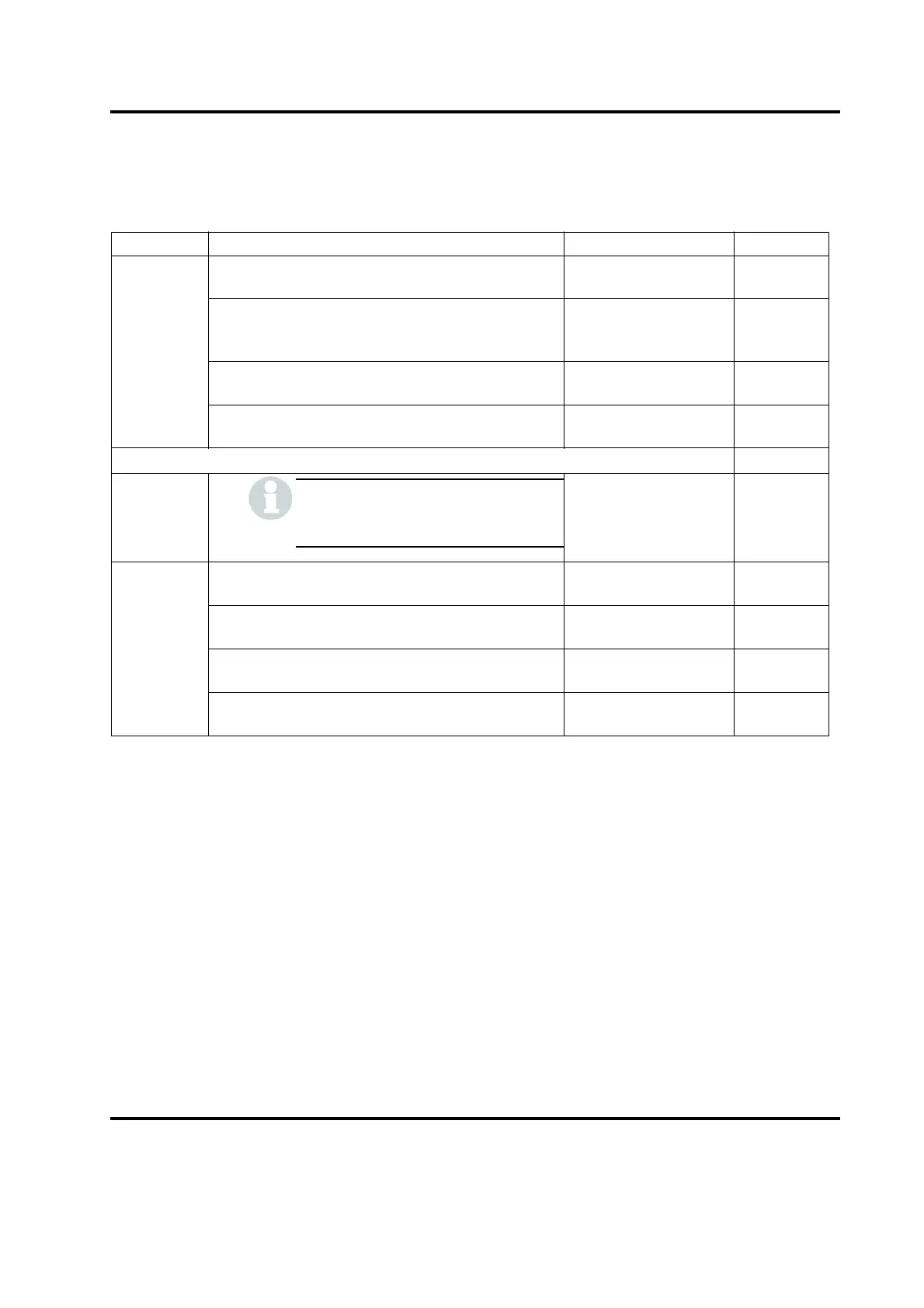

Table 4.9 DIP Switch Settings*

*Refer to Figure 4.15

4.7 Guards and Safety Equipment

4.7.1 Emergency Stop Control

If you use the Emergency Stop button on the Actuator to terminate a weld, twist the button to reset it. (The

welder will not operate until this button is reset.) You must then press Reset at the power supply. If you are

running automation, you can use external reset that is connected to your User I/O board.

Function Options Default Settings Sw Pos

Seek

Seek on power-up - Checks horn frequency upon

power up and stores the value in memory

Off 1

Auto-Seek - checks horn frequency once each

minute, from the time of the last activation of

ultrasonics

On (This default set-

ting renders Auto-

Seek inoperative)

2

Auto-Seek duration - indicates the length of time

the Auto-Seek function is active

On = short

Off = standard

3

Store at end of weld - updates horn frequency

memory at the end of each weld

Off 4

NOT USED 5

Amplitude

Control

DIP 6 must be in the Off position.

Off 6

Start

short - sets ramp time to 10 ms.

7-On

8-On

7 - 8

medium - sets ramp time to 35 ms.

7-Off

8-On

7 - 8

standard - sets ramp time to 80 ms*.

7-On

8-Off

7 - 8

long - sets ramp time to 105 ms.

7-Off

8-Off

7 - 8

Loading...

Loading...