Chapter 4: Installation and Setup

Installation Steps

4-18 011-003-991 EN

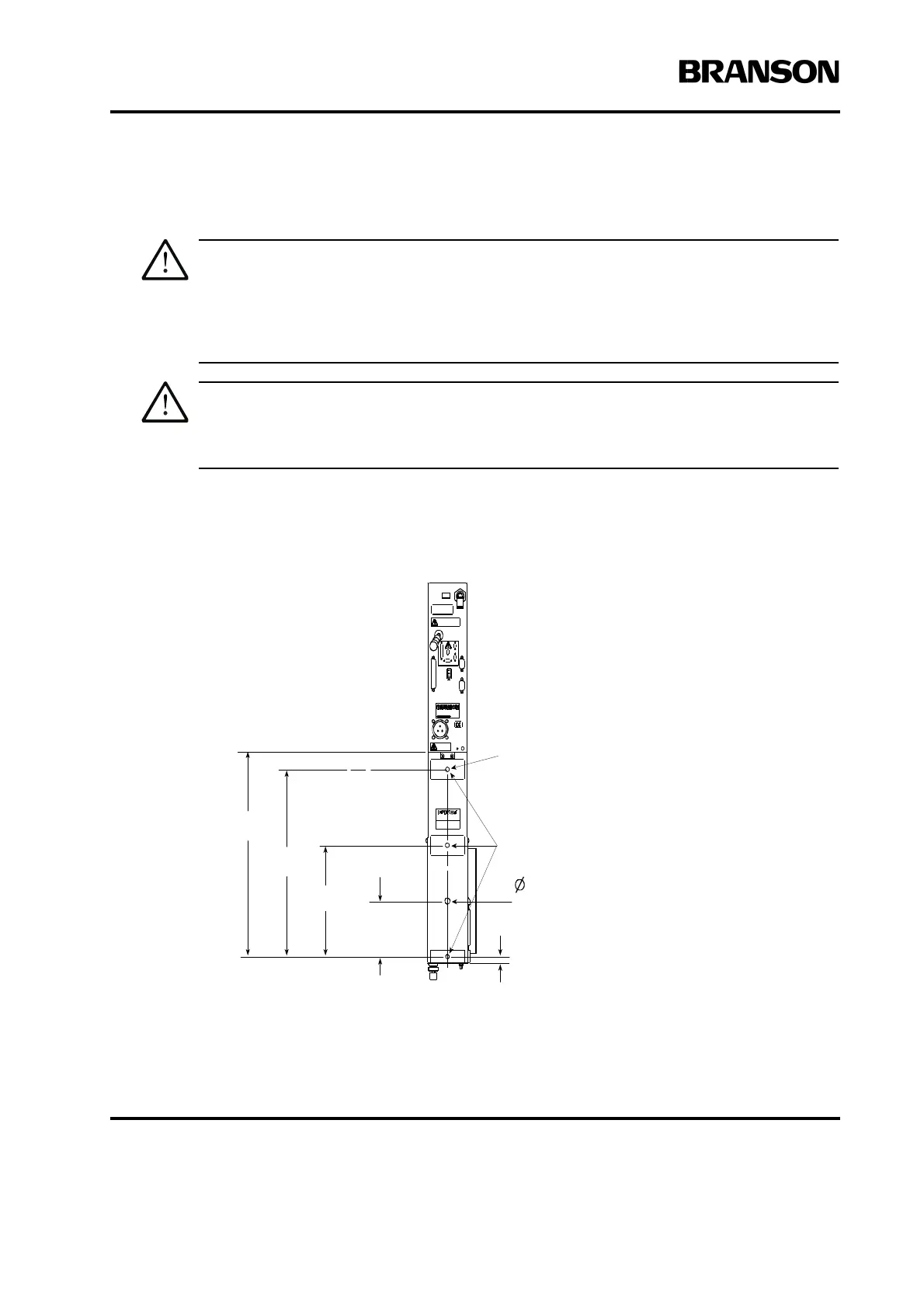

1. Lift the actuator from the box. Carefully lay the assembly on its right side (NOT on the side with the

linear encoder).

The actuator support bolts for the 2000-Series actuators are metric, M10 x 1.5 thread pitch,

25mm long. The support pin and mounting bolts must not extend more than 0.40 in (10 mm)

into the actuator, otherwise, binding or damage to the carriage may occur.

DO NOT use 900-Series M10 x 1.25 mounting bolts. They have a different thread pitch and

will not interchange with those used on the 2000-Series.

2. Use of a guide pin is suggested. It is not provided with the actuator. If you require a guide pin, use

a solid metal dowel pin, 12mm diameter, which must not extend into the actuator more than 0.40

inch (10mm) from your support.

Figure 4.8 Actuator Rear View, Mounting Surface, Bolt and Guide Pin Locations

For 12 mm

Dowel Pin

.477

M10 x 1.5 THDS

10 mm deep

(3 places)

4.25

108 mm

8.50

216 mm

14.30

363 mm

15.63

397 mm

50

13 mm

Machined mounting

surfaces (3 places)**

Rear view of ae/aed actuator is shown. Although

other actuators will vary in height, referenced

dimensions will be the same for all models.

**These three mounting surfaces are flat

within 0.004 in. (0.1mm) TIR, in a tolerance

zone of 16 x 3.5 in. (410 x 90 mm). The

surface to which the actuator is mounted

must also have the same flatness tolerance.

Loading...

Loading...