Parameter

structure

Keypad and

display

Parameter

x.00

Parameter

description format

Advanced parameter

descriptions

Macros

Serial comms

protocol

Electronic

nameplate

Performance

Feature look-

up table

Menu 12

Unidrive SP Advanced User Guide 197

Issue Number: 7 www.controltechniques.com

The variable selectors allow two source values (defined by Pr 12.08, Pr 12.28 and Pr 12.09, Pr 12.29) to be combined as defined by the mode (Pr

12.10, Pr 12.30) to produce an output (Pr 12.12, Pr 12.32) which can be routed to the destination parameter (defined by Pr 12.11, Pr 12.31). The

actions of the variable selector are defined by the mode parameter as given below. If the mode parameter is changed or the variable selector is

disabled because neither source is routed to a valid parameter all the internal state variables (i.e. time constant accumulator, etc.) within the selector

are reset. When the Sectional control mode is selected the function is also reset, and the output is held at zero, when the control (Pr 12.15 or Pr

12.35) is zero. It is active when the control has a non-zero value.

A loss of resolution can be seen when routing paraneter values through the variable selectors due to the maximum available resolution being two

decimal places. The variable select output is scaled to ensure a 100.00% output gives full scale output to the destination parameter. This results in

the destination parameter jumping in steps equivalent to 0.01% resolution if the destination parameter has a greater resolution than two decimal

places.

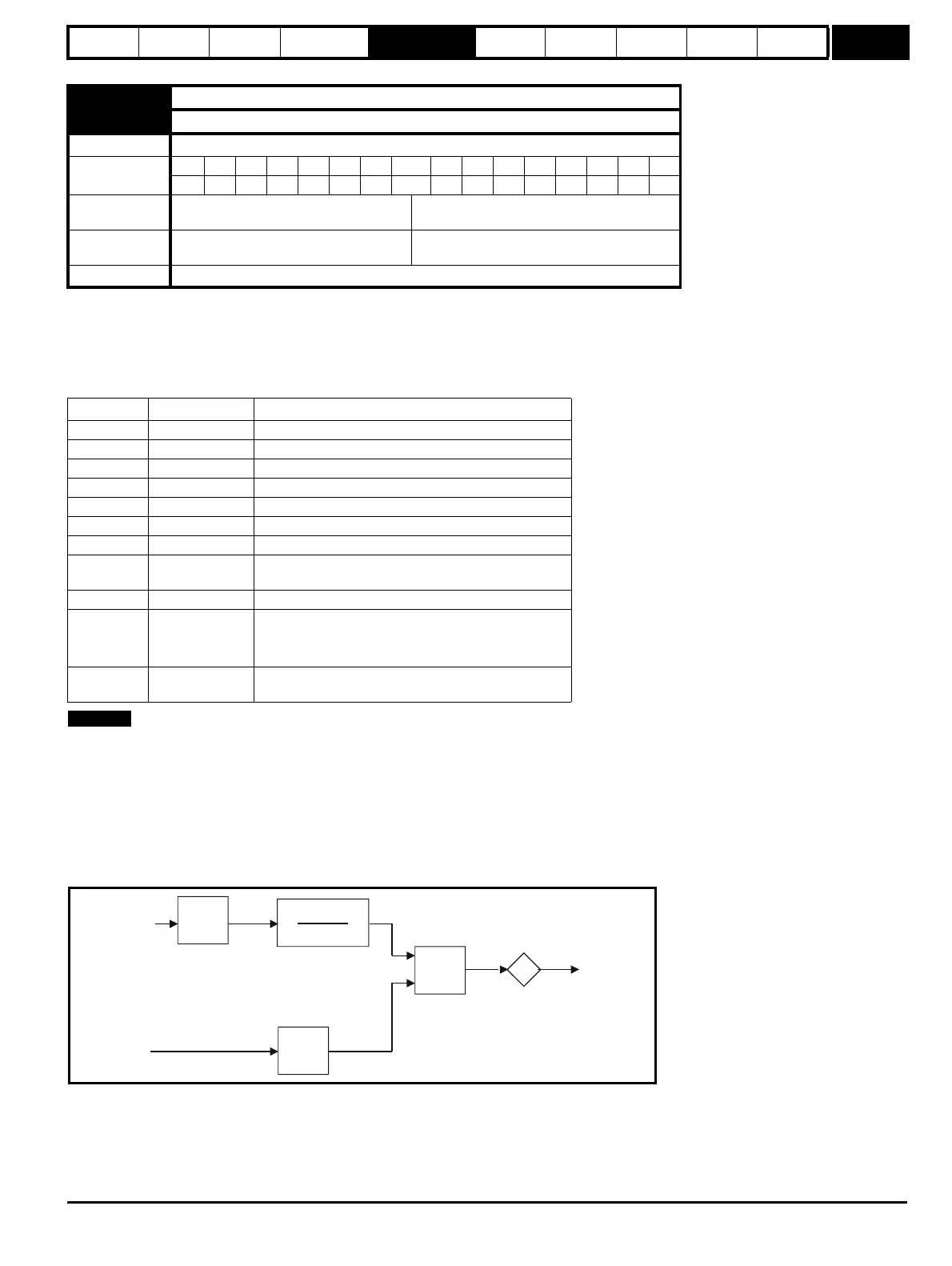

Sectional control

The sectional control function is intended to apply scaling and a speed offset to a 16 bit position value to generate a new 16 bit position value. The

output can be used as an input to the position controller (menu 13) or to generate an encoder simulation output via the SM-Universal encoder plus

module. This function can be selected for either variable selector, but the description below relates to variable selector 1.

The position input can be derived from any parameter, however it is intended to be used with a position value that has a range from 0 to 65535. The

input is scaled so that so that as Pr 12.13 is varied between -4.000 and 4.000 the proportion of the input position change added to the accumulator

varies from 0.000 to 2.000 (i.e. the change of position input value is added without scaling if Pr 12.13 is 0.000). The remainder from the scaling

division is stored and then added at the next sample to maintain an exact ratio between the position input and the position output, provided the speed

input is zero. The controller only takes the change of position from the input source parameter, and not the absolute value, so that when the controller

is first made active the output does not jump to the source position, but only moves with any changes of source position after that point in time.

12.15 Variable selector 1 control

12.35 Variable selector 2 control

Drive modes Open-loop, Closed-loop vector, Servo, Regen

Coding

Bit SP FI DE Txt VM DP ND RA NC NV PT US RW BU PS

2 111

Range

Open-loop, Closed-loop vector, Servo,

Regen

0.00 to 100.00

Default

Open-loop, Closed-loop vector, Servo,

Regen

0.00

Update rate Background

Mode value Action Result

0 Select input 1 output = input1

1 Select input 2 output = input2

2 Add output = input1 + input2

3 Subtract output = input1 - input 2

4 Multiply output = (input1 x input2) / 100.0

5 Divide output = (input1 x 100.0) / input2

6 Time constant output = input1 / ((control param)s + 1)

7 Linear ramp

output = input1 via a ramp with a ramp time of (control

param) seconds from 0 to 100%

8 Modulus output = | input1 |

9 Powers

control = 0.02: output = input1

2

/ 100.0

control = 0.03: output = input1

3

/ 100.0

2

control has any other value: output = input1

10 Sectional control

control = 0.00: disabled, accumulator reset and output

zero control <> 0.00: output as defined below

NOTE

%

4.000 + 12.13

4.000

12.14

Σ

Position

input

Position

output

Speed

input

d/dt

Accumulator

http://nicontrols.com

Loading...

Loading...