AV7000 LINEAR CAMERA REFERENCE MANUAL

Internal Tach: This is a software-generated pulse mimicking an encoder/tachometer.

PGD100 Speed Detector: Used with tilt-tray or cross-belt sorters. This detector uses a

series of photoelectric sensors to determine the conveyor speed.

The position sensor (DM3610, RangeFinder, or light curtain (DS2)) is often used as a trigger

source. When the height or left/right focus data measured by the sensor goes over a certain

threshold, then a package is entering the image valid start, and when it goes under the

threshold, the package is providing the image valid stop. Sometimes this sensor is not

sufficiently precise and an additional "Presence Sensor" (AS1 or photoelectric sensor) input

is used. An additional photoelectric sensor or conveyor controller signal is usually connected

to this input.

When the codes are on more than one face of the parcel, more than one barcode reader-

illuminator pair is necessary (multi-camera reading station). In this case, one of the barcode

readers (the "Master") collects the information from all the sensors and distributes it to the

other barcode readers using a dedicated ethernet connection.

A CBX connection box can be used to simplify the connection of the camera to the other

system components (photoelectric sensors, encoders, height sensors, and etc.).

A typical reading station will also include:

Power Supply Systems: The AV7000 requires a 24 Vdc power supply. Usually each

barcode reader-illuminator pair has its own power supply system (i. e. PWR-480B).

Connection Boxes: CBX100, CBX500, CBX510, or CBX800

Height/Side Position Sensor: RangeFinder, DM3610, or light curtain

External Deflection Mirrors: To cover the requested reading field, the cameras must be

positioned at a given distance from their targets. In order to create reading stations as

small as possible, a deflection mirror is often inserted between the target and the barcode

reader.

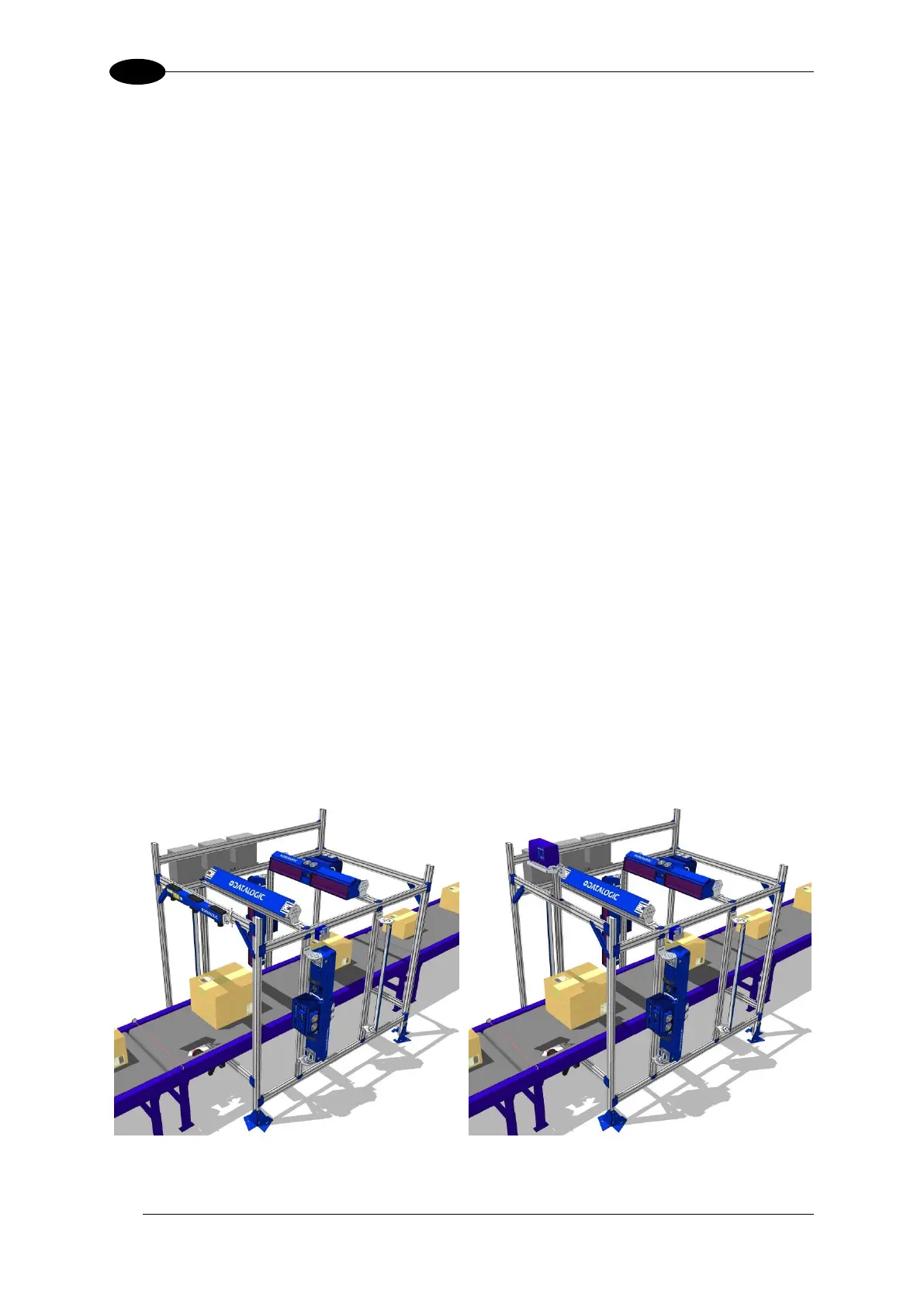

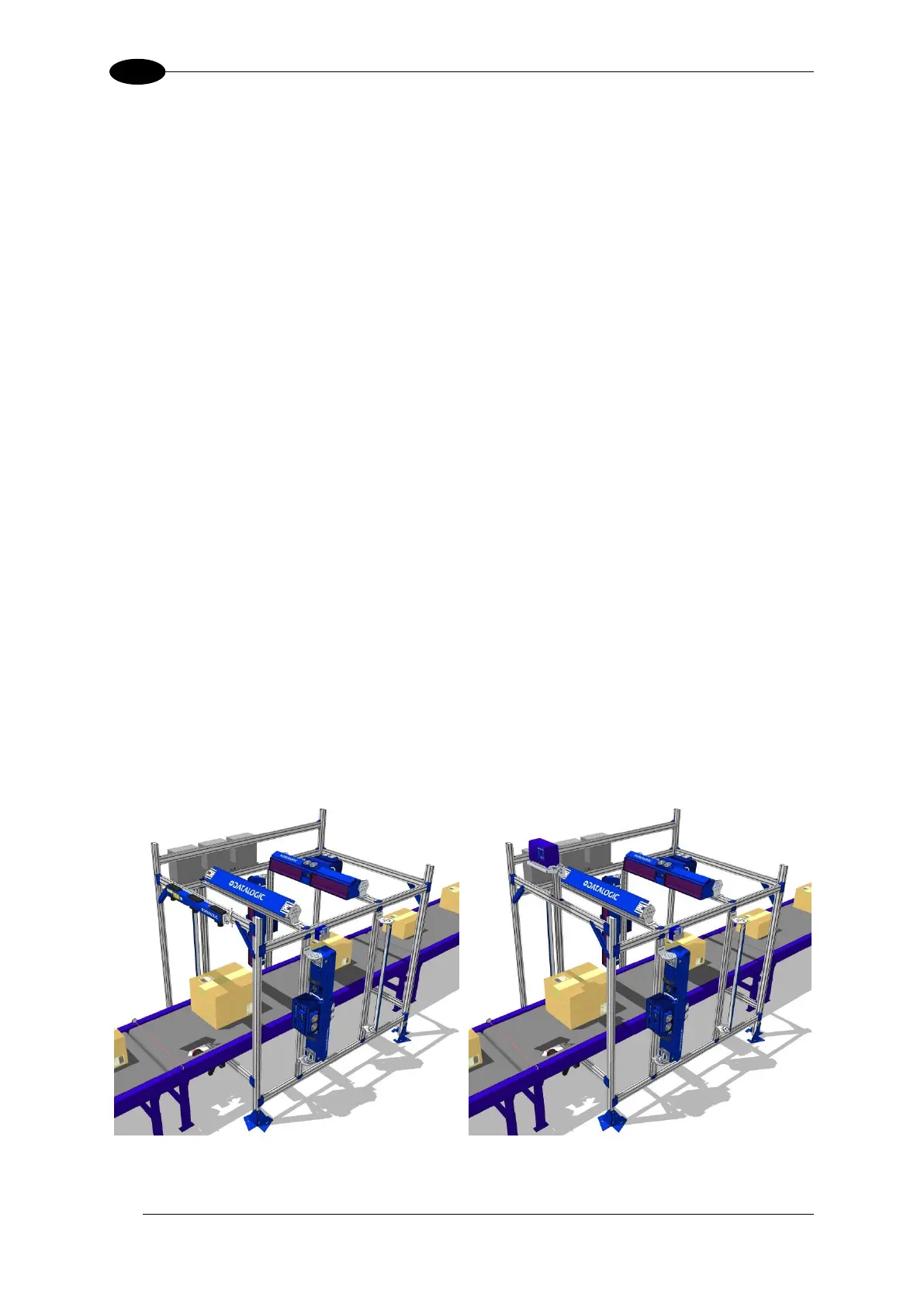

Figure 5: Typical Reading Station with RangeFinder (left) and DM3610 (right)

Loading...

Loading...