IMAGING FEATURES

7. Measure the conveyor width (the distance from the left side camera’s far working

distance point to the right side camera’s far working distance point measuring across the

conveyor) and add that value into e-Genius. See section 4.5.1 Modify Settings | Global

Settings | Operating Mode.

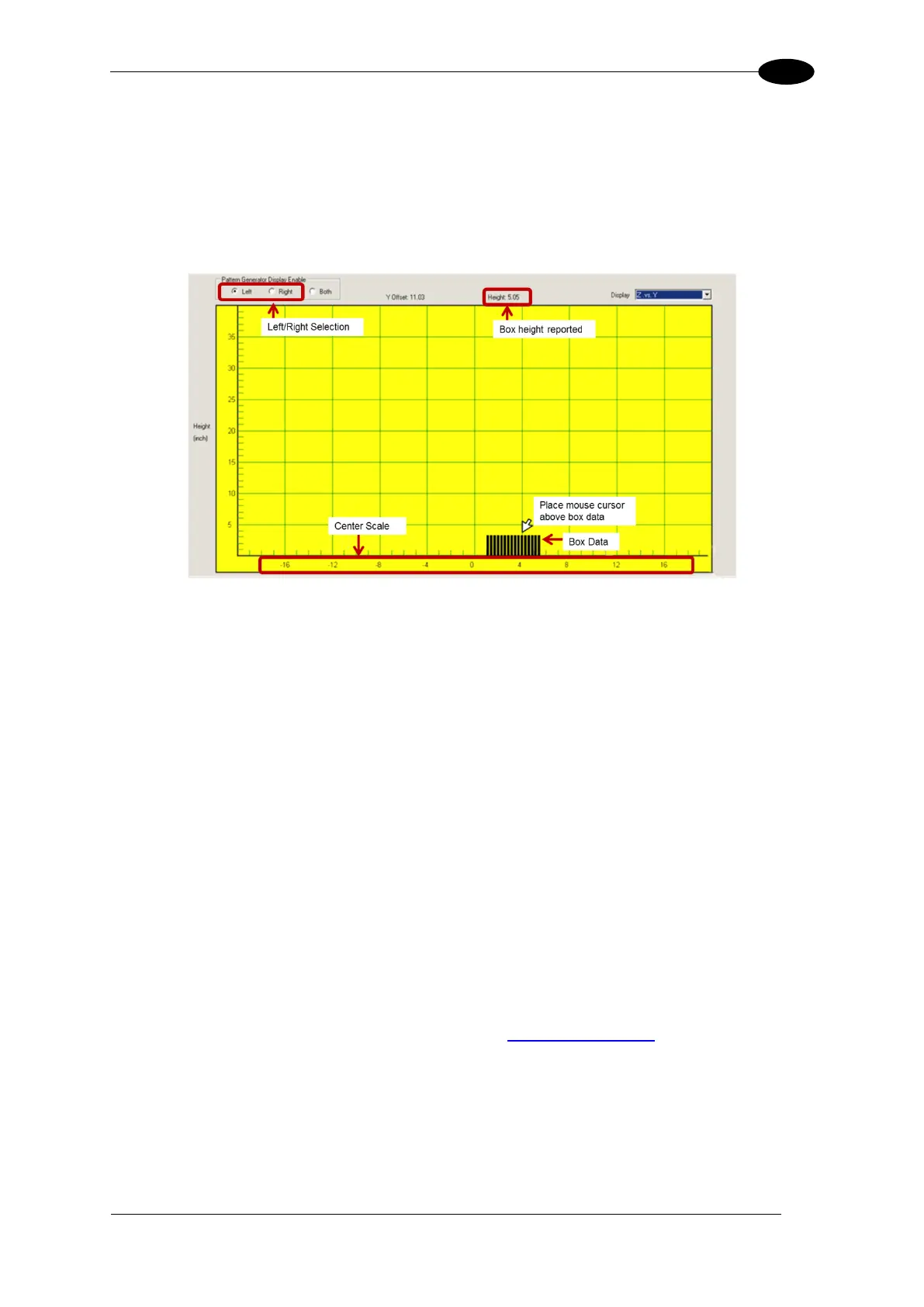

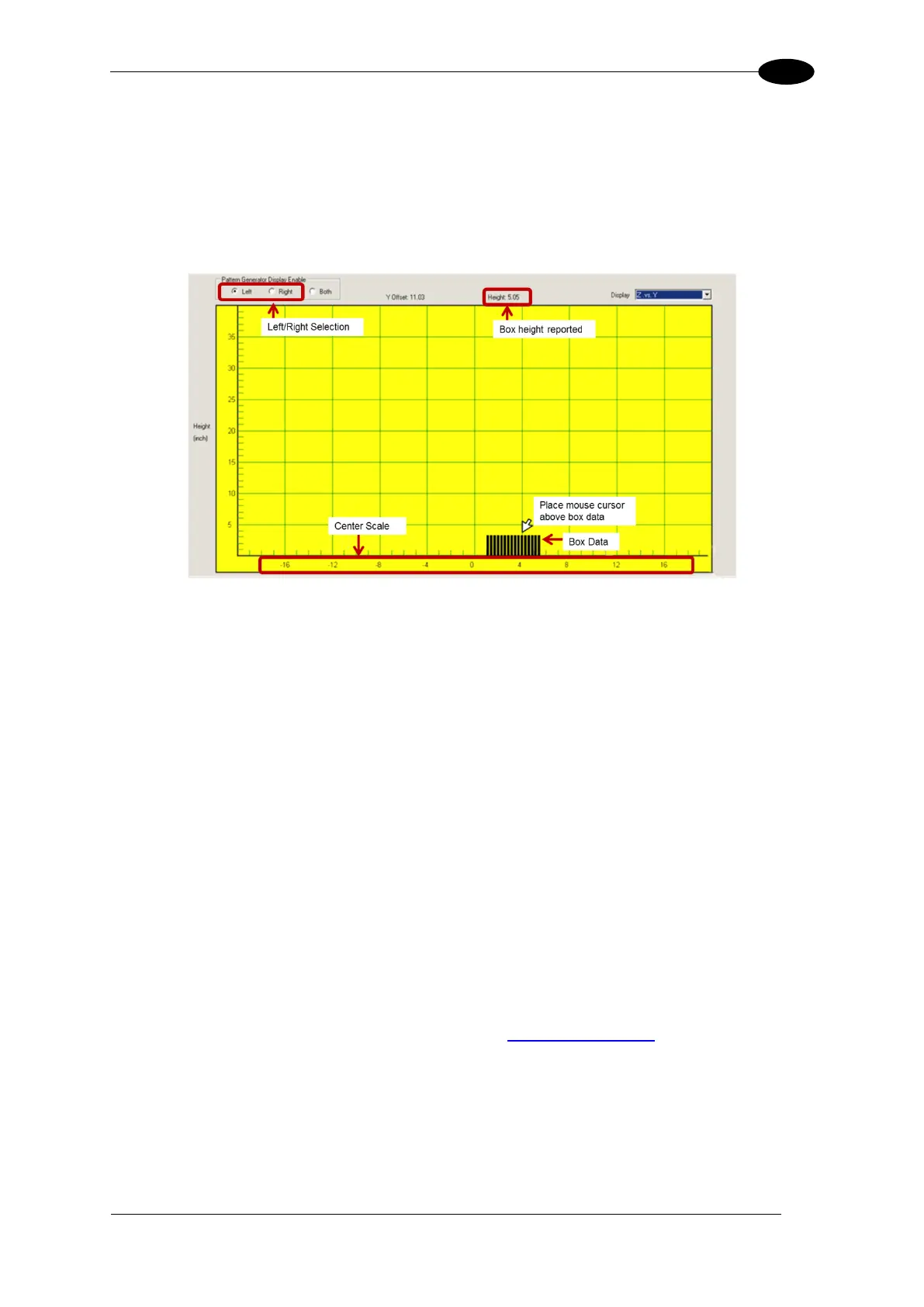

8. Identify how many inches the Box Data is found from the center 0 found in the Center

Scale of the CodeWord Viewer.

Example:

With a 28 inch wide conveyor, if the box is located exactly at the 0 (zero) line in the Code

Word Viewer Center Scale, a Left Ignore Limit of 14 and a Right Ignore Limit of 15 is

entered into the AV7000 e-Genius RangeFinder parameters (See 4.5.1).

In the example above the box is found on the one inch increment mark of the Center

Scale line. Since the box is on the positive side of the 0 reference then the following

values will be added into the left/right field if the RangeFinder mounting parameters:

Left: –15

Right: +13

5.2.3 Setting up an AV7000 System Using an LCC-75XX KIT with DS2

Light Array

The DS2 AREAscan™ Light Array is a multibeam optoelectronic devices that can be used to

detect objects, including small and transparent targets as well as for measurement detection.

Reference the DS2 Instruction Manual available at www.datalogic.com.

The device consists of emitter and receiver units, which generate infrared beams that detect

any object positioned in the light grid’s detection field.

The command and control functions are inside the two units; the connections are made

through M12 connectors located in the lower side of the profiles. The synchronisation

between the emitter and the receiver takes place via cable through direct connection

Loading...

Loading...