PID Control 83

User Guide v 2.3 — September 2015 Making Adjustments

When all selected zones complete the ART process, a checkmark will appear for each

zone.

3. To cancel the ART process at any time, touch the Cancel ART Process button.

7.7 PID Control

Altanium offers the choice of using ART (automatic tuning), or PID (manual tuning). To use

PID on a zone or zones, the following provides a simple explanation of each parameter (P, I,

and D).

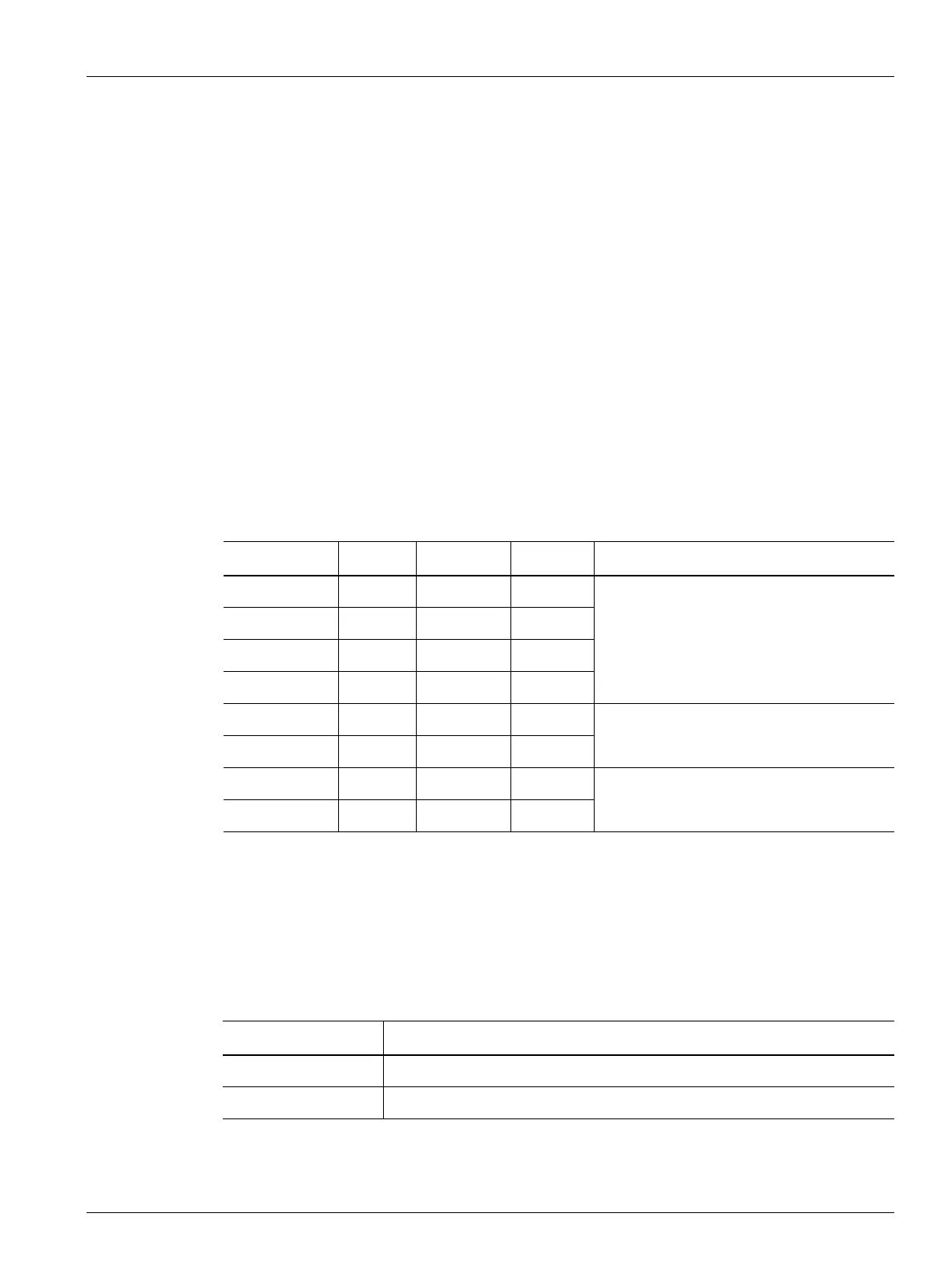

7.7.1 Typical PID Values

The following is a list of some typical PID values.

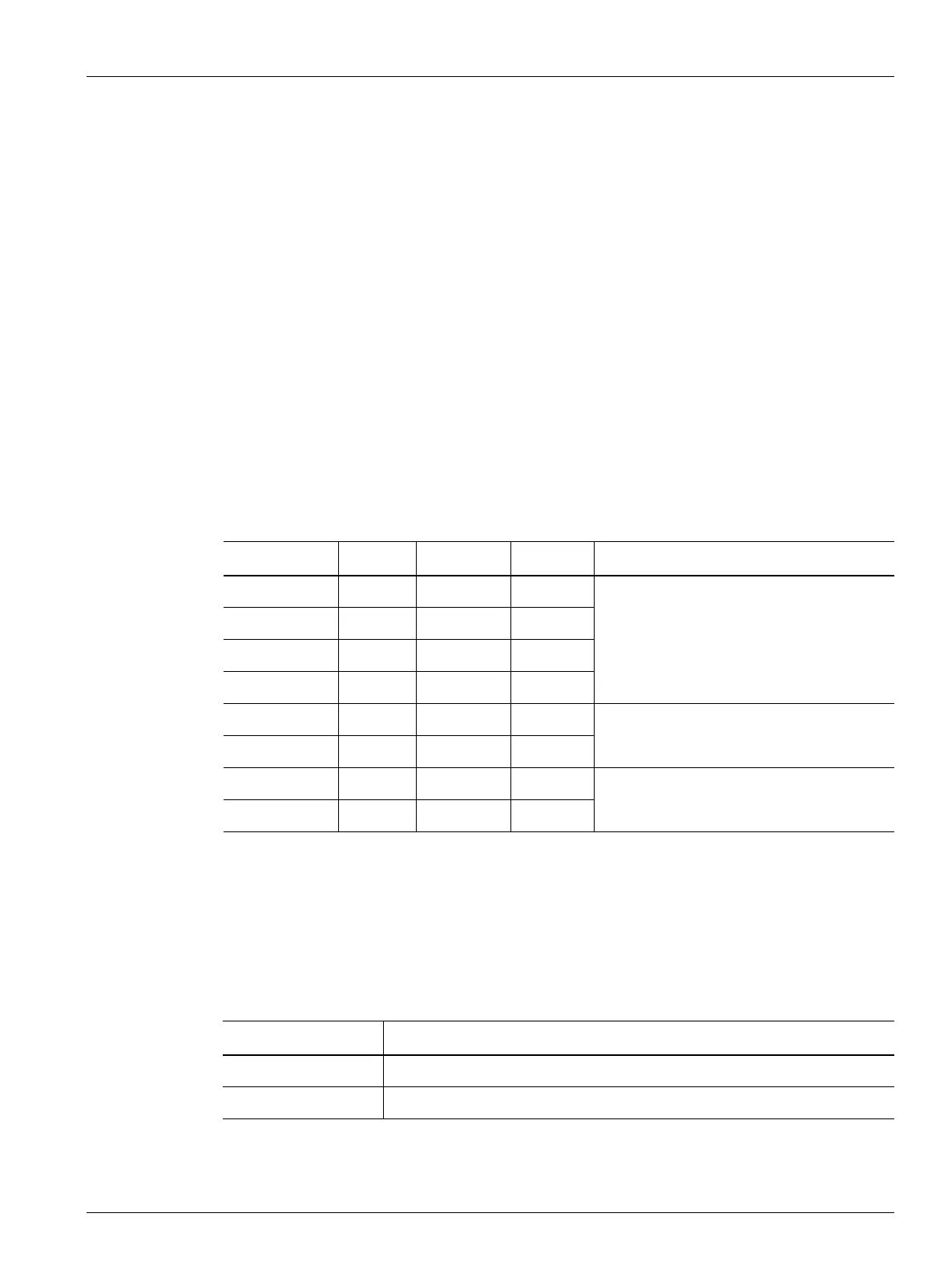

7.7.2 Possible Causes of Oscillation

It is possible to set the control terms incorrectly, inducing an oscillation. The following are the

most common causes:

Table 7-6 PID Values

Proportional Integral Derivative Type Example

015 010 002 Fast Probes or heaters with internally located

thermocouples

050 020 000 Fast

020 010 000 Fast

015 015 000 Fast

020 007 100 Medium Probes or heaters with internally located

thermocouples (larger mass)

020 005 200 Medium

100 003 000 Slow Manifolds or heaters with externally

located thermocouples

075 003 150 Slow

Table 7-7 Possible Causes of Oscillation

Cause Description

"P" too large Power change too great per °C of temperature change.

"I" too large Power changing too quickly for the process to follow it.

Loading...

Loading...