Alarm: Position Deviation Limit Exceeded 217

User Guide v 2.3 — September 2015 UltraSync-E, If Equipped

16.8.2 Alarm: Position Deviation Limit Exceeded

This fault occurs when the valve stems position deviates from set position, by more than the

value of the Position Alarm Window setting. The alarms can be cleared but may reappear

immediately or during the next valve stem movement if the problem still remains.

Possible causes for this fault include:

• Opening or Closing Force Limit are set too low

• Position Monitoring Window is set too small

• Resin in the system is too cold or the temperature zone setpoints are set too low

• A physical obstruction of the valve stem plate

• Damaged component

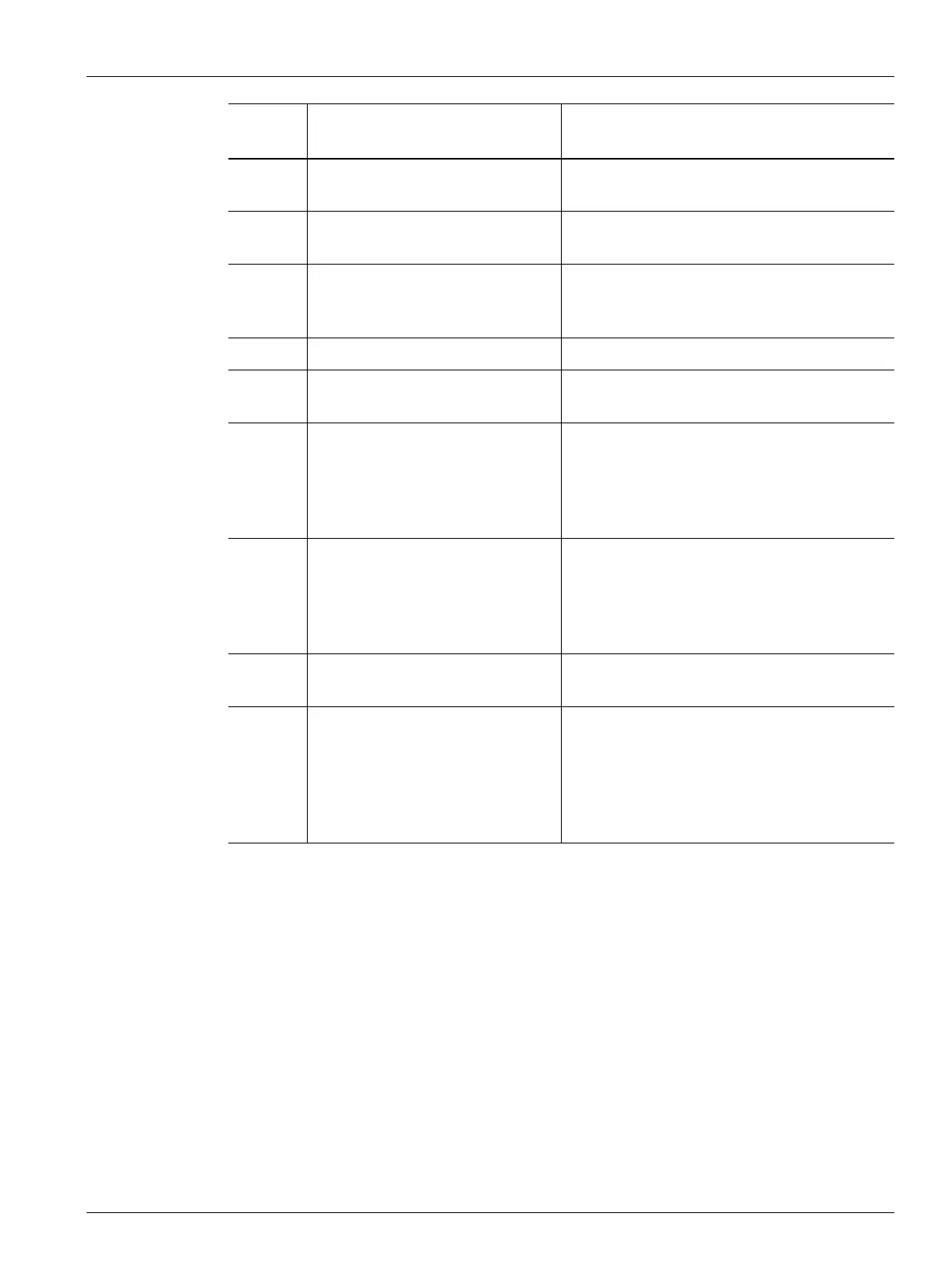

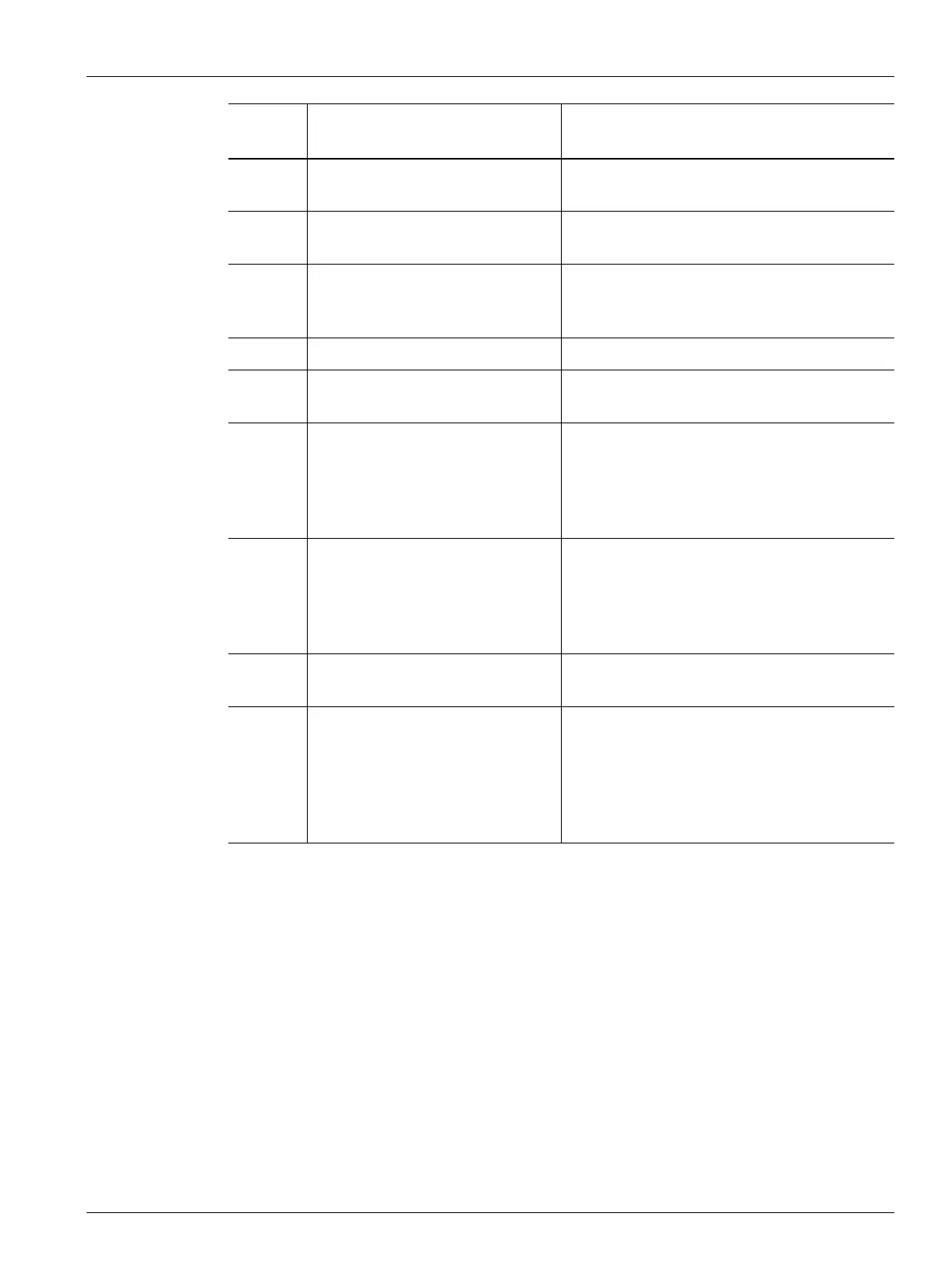

98 Motor over temperature Let motor cool down. Increase cycle time (cycle

time should not be less than 3sec).

99 Error I

2

t > 100% Let motor cool down. Increase cycle time (cycle

time should not be less than 3sec).

115 Cable break encoder 1 Check to make sure black encoder cable is

connected between motor and drive and not

damaged.

123 Field angle error Check black encoder cable for shield damage.

146 Encoder module 1 is missing Module A in the drive is missing or faulty.

Replace if necessary.

192 Position deviation dynamic Motor position has exceeded its control

position. Make sure injection is not occurring

until stems are in the open position (do not

inject while stems are opening). Try decreasing

hold pressure.

193 Position deviation static Motor position has exceeded its control

position. Make sure injection is not occurring

until stems are in the open position (do not

inject while stems are opening). Try decreasing

hold pressure.

200 Homing necessary and not yet

executed

Perform calibration. Cycle power to drive.

208 Drive is blocked Motor is blocked/stalled that was not detected

by obstruction detection software or torque

limit exceeded for a prolonged period of time.

Perform calibration. Check for obstruction in

valve stem actuation system. Cycle power to

drive.

Fault

Number

Fault Solution

Loading...

Loading...