61

11 Parameterization

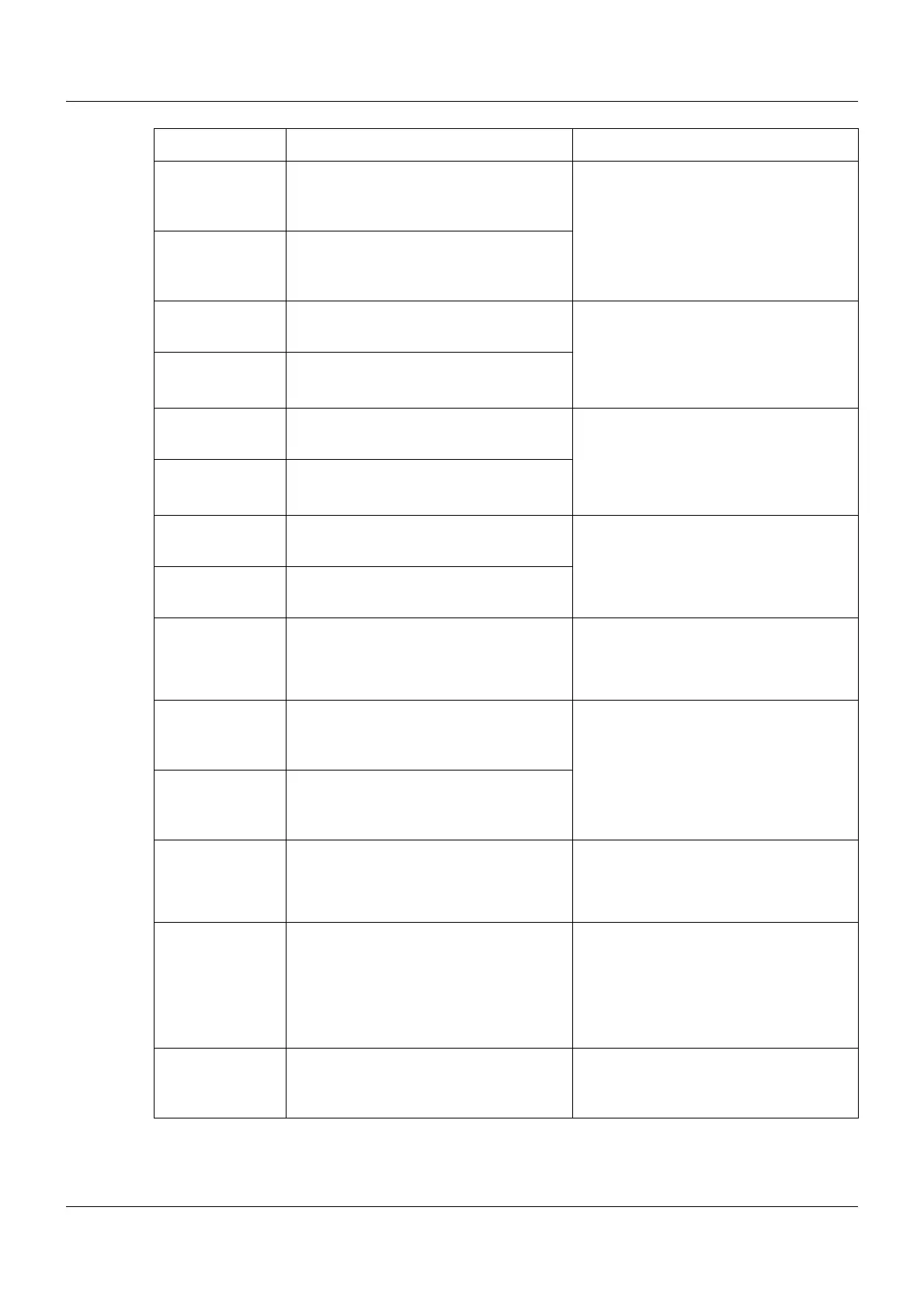

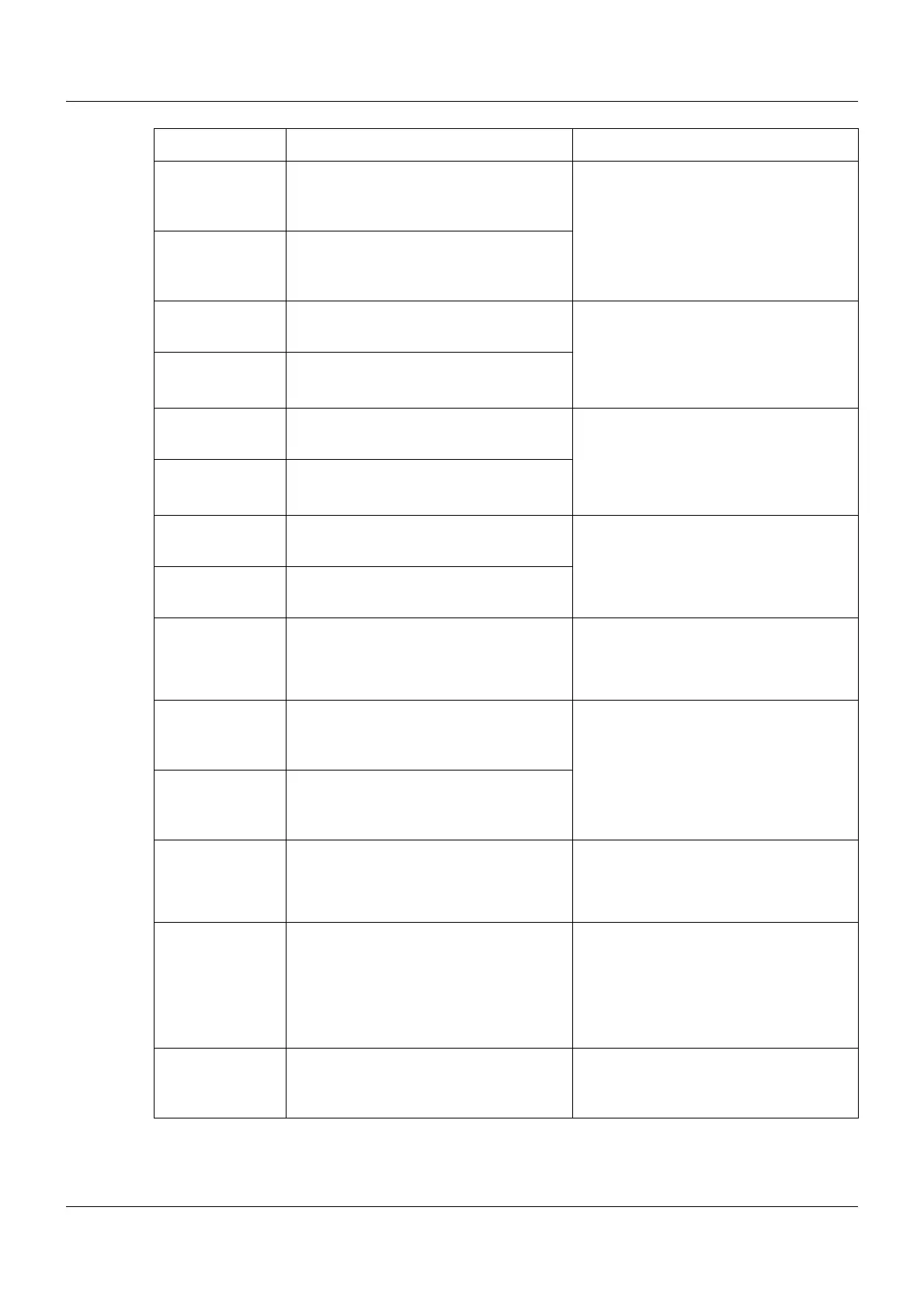

Parameter Setting Description

Proportional band

1

(Xp1)

0 to 9999 Value for the proportional band

The controller structure has no effect if

Xp = 0 (behavior identical to limit value

monitoring function)!

For a continuous controller, Xp must be

> 0.

Proportional band

2

(Xp2)

0 to 9999

Derivative time 1

(Tv1)

0 to 80 to 9999 s The derivative time influences the differ-

ential component (D component) of the

controller output signal.

The greater the derivative time, the

more effect the D component has.

Derivative time 2

(Tv2)

0 to 80 to 9999 s

Reset time 1

(Tn1)

0 to 350 to 9999 s The reset time influences the integral

component (I component) of the control-

ler output signal.

The greater the reset time, the less

effect the I component has.

Reset time 2

(Tn2)

0 to 350 to 9999 s

Cycle time 1

(Cy1)

0 to 20 to 999.9 s When using a switched output, the cycle

time should be chosen so that the

energy supply to the process is as con-

tinuous as possible, and the switching

elements are not overloaded.

Cycle time 2

(Cy2)

0 to 20 to 999.9 s

Contact spacing

(Xsh)

0 to 999.9 Spacing between the two control con-

tacts for a three-state controller, three-

step controller, and continuous control-

ler with integrated position controller

Switching differ-

ential 1

(Xd1)

0 to 1 to 999.9 Hysteresis for a switching controller with

proportional band Xp = 0

Switching differ-

ential 2

(Xd2)

0 to 1 to 999.9

Actuator time

(TT)

5 to 60 to 3000 s Control valve runtime range used for a

three-step controller and continuous

controller with integrated position con-

troller

Working point

(Y0)

-100 to 0 to +100 % Working point correction for a P or PD

controller (correction value for the output

level)

If the actual value (x) has reached the

setpoint value (w), the output level (y)

corresponds to the working point (Y0).

Max. output level

limit

(Y1)

0 to 100 % Admissible maximum output level (only

effective if Xp > 0)

Loading...

Loading...