OUTLINE

05–00–2

End Of S ie

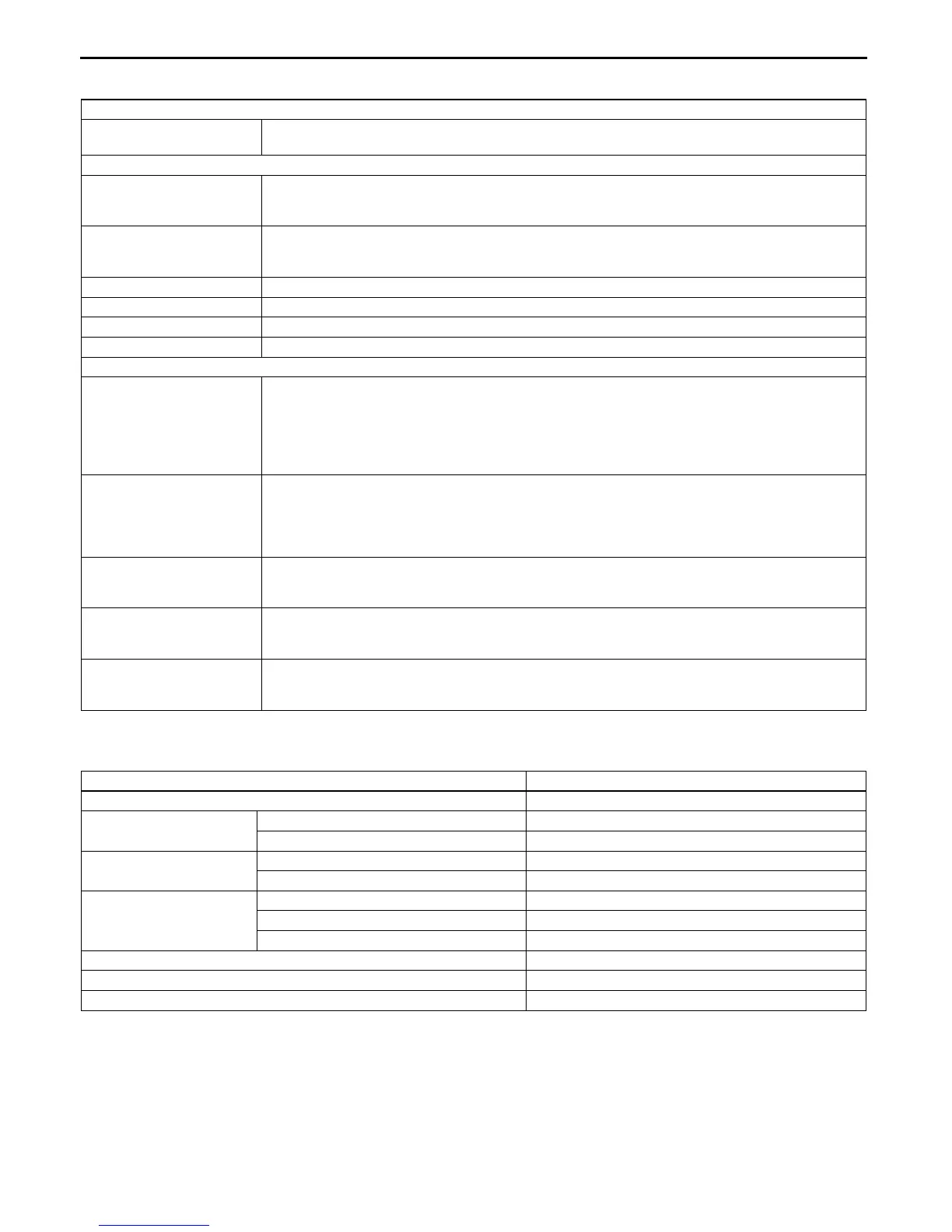

TRANSMISSION/TRANSAXLE FEATURES

CHU050001030S02

End Of Sie

CLUTCH SPECIFICATIONS

CHU050001030S03

End Of Sie

CLUTCH

Increased torque

transmission capacity

• The clutch cover set load has been increased.

• Torsional spring tension has been reduced to reduce NVH.

MT

Improved operability

• A ball-type synchromesh mechanism has been adopted.

• A triple synchronizer mechanism has been adopted for 1GR, 2GR and 3GR.

• Bushings for the control rod have been adopted.

Improved driveability

• In order to obtain more power from the engine, the total gear ratio has been reduced in speed

and set in a cross pattern.

• To improve drivetrain rigidity, a closed section power plant frame (PPF) has been adopted.

Improved fuel economy • Six-speed Y16M-D manual transmission has been adopted.

Improved marketability • Six-speed Y16M-D manual transmission has been adopted.

Improved reliability • A double engagement prevention mechanism (interlock mechanism) has been adopted.

Mis-shift prevention • A reverse lockout mechanism has been adopted.

AT

Superior shift quality

• Direct electronic shift control by duty-cycle solenoids has been adopted.

• Feedback control system has been adopted.

• Centrifugal balance clutch chamber has been adopted.

• A plate-type clutch pack replaces the band brake in the 2-4 brake.

• Shifting assist at high engine speeds has been achieved due to adoption of an engine-

transmission total control system.

High efficiency,

compactness, lightweight

• A miniature trochoid gear oil pump with torque converter direct drive has been adopted.

• Due to complete electronic control of clutch engagement and release pressure, the forward

one-way and overrunning clutches have been eliminated.

• Due to the adoption of direct electronic clutch pressure control (direct electronic shift control),

the accumulators have been eliminated.

Improved reliability,

reduced NVH (noise,

vibration, and harshness)

• A pleat type oil strainer with fine mesh has been adopted.

• A highly rigid transmission case has been adopted.

Improved driveability

• To improve drivetrain rigidity, a closed section power plant frame (PPF) has been adopted.

• A control feature for climbing/descending hills has been adopted, improving driveability when

climbing/descending.

Improved marketability

• The Sport AT has been adopted. With this feature up and downshifting can be performed with

either the shift control switch on the steering wheel or with the one-touch operation of the

selector lever.

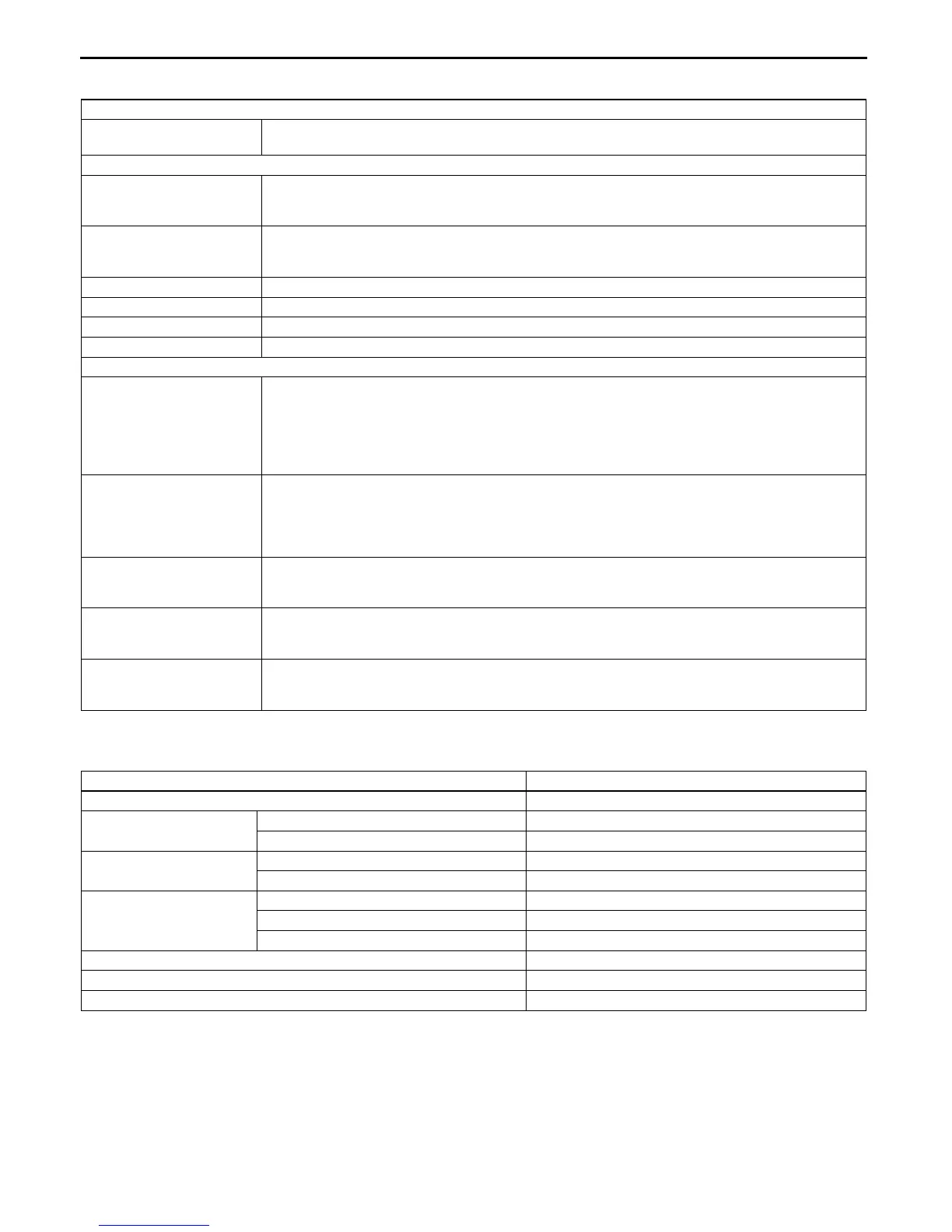

Item Specifications

Clutch control Hydraulic

Clutch cover

Spring type Diaphragm

Set load (N {kgf, lbf}) 6,470 {660, 1,455}

Clutch disc

Outer diameter (mm {in}) 236 {9.29}

Inner diameter (mm {in}) 160 {6.30}

Clutch pedal

Type Suspended

Pedal ratio 5.7

Full stroke (mm {in}) 130 {5.118}

Clutch master cylinder inner diameter (mm {in}) 15.87 {0.6248}

Clutch release cylinder inner diameter (mm {in}) 19.05 {0.7500}

Clutch fluid type SAE J1703 or FMVSS 116 DOT-3

Loading...

Loading...