MECHANICAL

01–10–18

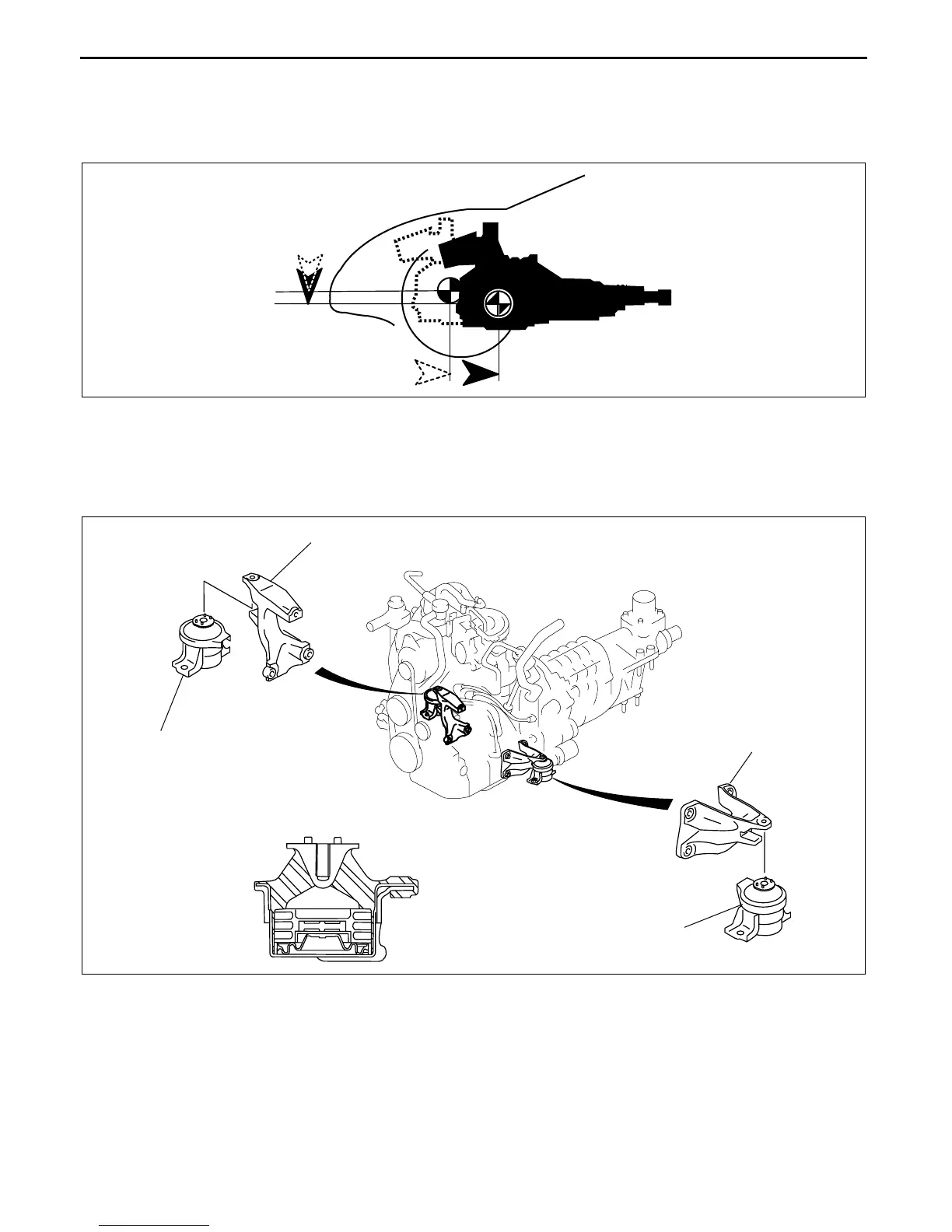

ENGINE MOUNT OUTLINE

CHU011039000S01

• With the adoption of a naturally aspirated engine, an ideal engine layout (advanced front-midship layout) has

been realized by the engine being positioned approximately 60 mm {2.36 in} further rearward and

approximately 39 mm {1.54 in} further downward than the previous engine. This has been made possible by

reducing the height the oil pan and placing intake air related parts at the front of the engine.

End Of Sie

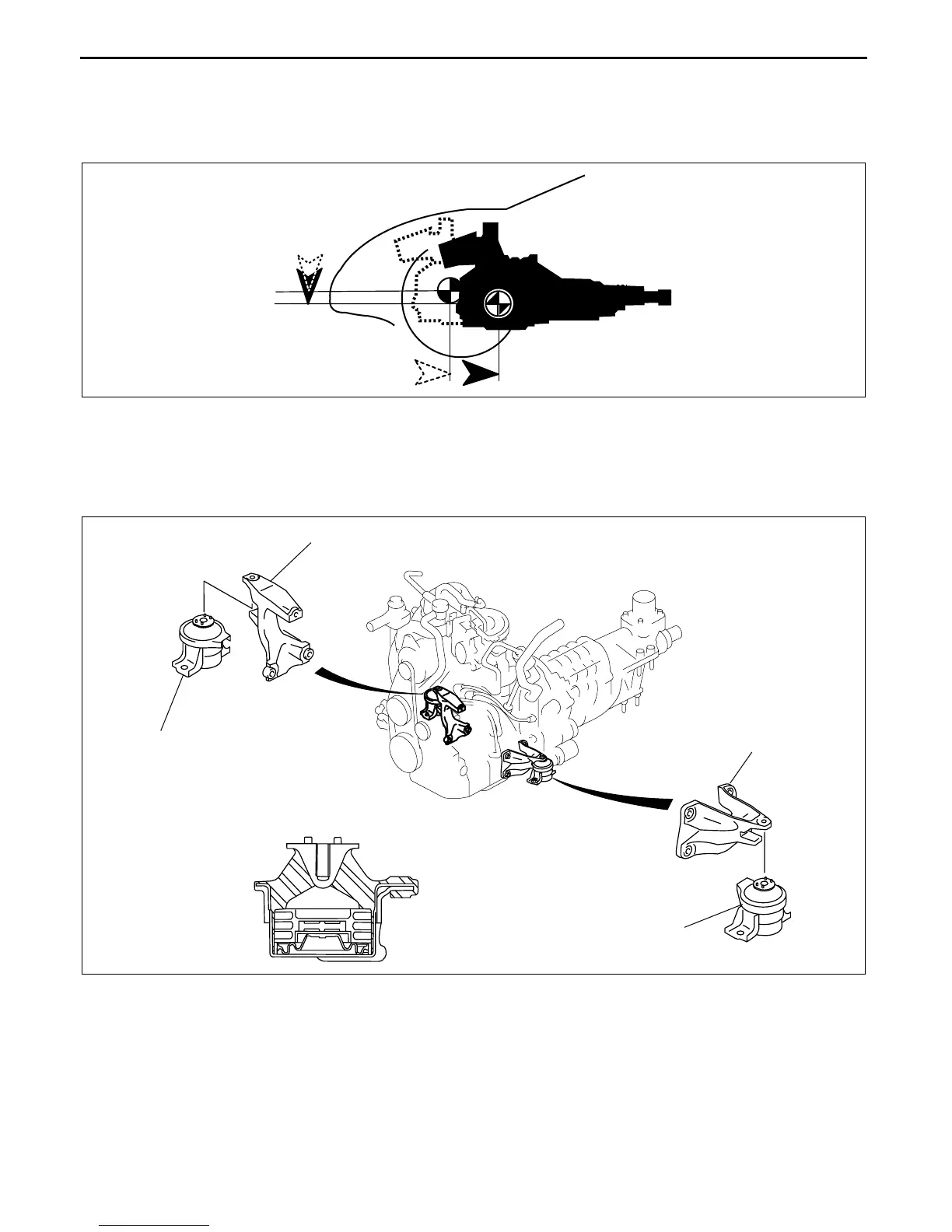

ENGINE MOUNT CONSTRUCTION

CHU011039000S02

• The use of mount rubber to support areas under the engine where there is less vibration as well as oil-filled

mount rubber has reduced engine vibration.

• With the adoption of aluminum engine mount brackets, weight reduction have been achieved.

End Of Sie

BHJ0110N022

ENGINE MOUNT BRACKET (RH)

ENGINE MOUNT RUBBER (RH)

ENGINE MOUNT RUBBER

ENGINE MOUNT RUBBER (LH)

ENGINE MOUNT BRACKET (LH)

CHJ0110S021

Loading...

Loading...